Aerosol Related Infrastructure

Aerosol Related Infrastructure provides measurement capabilities to the DOE Atmospheric Radiation Measurement (ARM) program. Approximately six full-time scientific and professional staff work to meet the goal of providing long-term measurements of aerosols and their precursors across a global network of ground- and aircraft-based locations.

Mobile Laboratory Design and Integration

Beginning in 2009, a new deployment strategy was developed for mobile Aerosol Observing Systems (AOS). As part of the American Reinvestment and Recovery Act, three new AOS systems were designed and integrated at BNL.

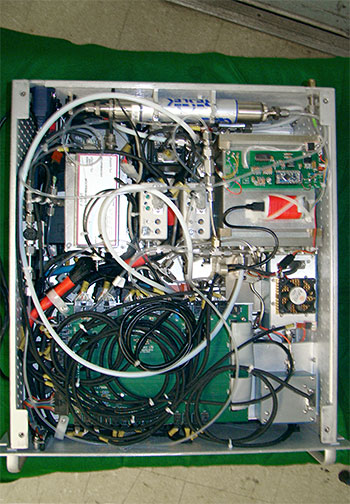

These mobile laboratories are designed to be self-contained, requiring just power and internet, stations complete with an array of instrumentation for characterizing aerosol number concentrations, size distributions, optical properties, hygroscopicity, cloud-forming propensity and supporting measurements. Unlike previous ARM mobile laboratories the instrumentation is permanently installed in shock-mounted racks for ease of transportation and in-field set up. The inside of the structures provides a climate controlled laboratory space.

Based on the success of the earlier systems, ARM asked BNL to build two new additional systems, the first to be deployed to the North Slope of Alaska as part of the AMF3 and the second to replace a 25-y old AOS at the Southern Great Plains site.

Self-contained mobile laboratory.

Climate controlled laboratory space.

To date, these units have been deployed in desert, arctic, mountain, and tropical environments. The AMF2 AOS is capable of marine deployments and has operated for months at a time on ships. A super-site, the Mobile Aerosol Observing System (MAOS), consists of 2 containers and has all the instrumentation of the basic AOS plus extended instrumentation for trace-gas precursors and aerosol characterization.

Instrument Design and Modification

Instruments provided for ARM must be capable of long-term deployments and operation under adverse weather conditions with minimal on-site support by on-site technicians who may have only a background in general instrumentation. Instrumentation is either commercial units modified for these applications or custom units built at BNL or in conjunction with vendors.

Vacuum UV fluorescence detector designed and built in cooperation with Resonance Limited, Inc.

Three channel oxides of nitrogen for airborne

deployment. Custom designed and built by Air Quality Design, Inc.

Field Campaign and Permanent Measurement Site Support

The group provides on-site and remote support to the five current AOS systems. This support consists of on-site training for new shifts of Operators, repair, calibration and maintenance visits, remote monitoring of instrument operation and coordinating Operator activities on a daily basis.

Upcoming field campaigns include deployments on an Antarctic supply ship, on the plains of Argentina and a year-long stint on a German research ice-breaker in the Arctic. This continues ARM’s record of making measurements in some of the harshest environments on earth.

The AMF2 AOS (center) during a deployment at the ARM Southern Great Plains site.

(L to R) Art Sedlacek, Chongai Kuang and Stephen Springston aboard the DOE AAF.

ARM Aerial Aircraft (AAF) Support

The group supports aircraft operations for a complete suite of trace-gas instrumentation and a Single Particle Soot Photometer.

Software Development

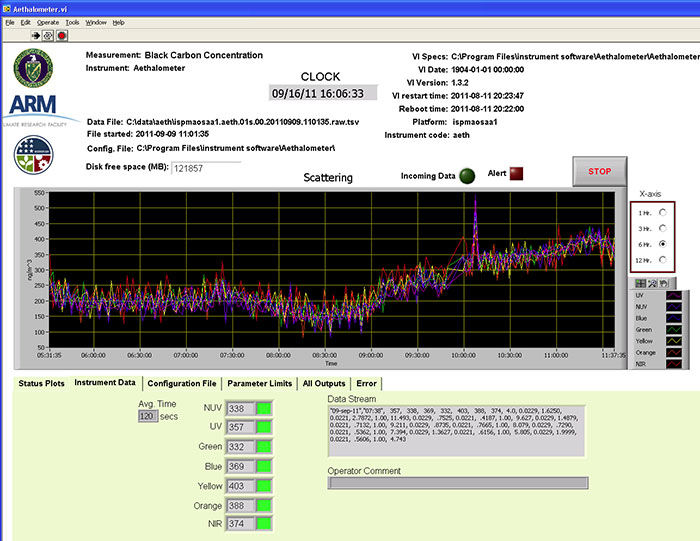

The wide variety of instruments, both custom made and commercial, come with widely disparate software for operation and data acquisition. This presents support and training challenges. To simplify support, training and data processing, a uniform set of programs with an identical Graphical User Interface has been written for all the major instrument systems. This GUI is the front end of a series of LabView programs that ingest the raw instrument data and save a flat ASCII file at 1-s time resolution for all instruments with all instrument data including comprehensive meta data.

In addition, the AOS provides multiple redundant levels of data storage. Each instrument computer saves at least 1-y of raw data locally. A second local computer saves a copy of these data. The local site data system ingests these local files for transmittance and archival storage at the ARM Data Management Facility.

Using the networking capabilities of ARM and the software developed at BNL, Mentors are able to remotely access all instrumentation and the infrastructure of the AOS units.

Documentation, Data Sets and QA/QC

A comprehensive electronic documentation suite is provided for Operators. This Standard Operating Procedure covers each instrument system as well as the custom infrastructure of the AOS. Regular maintenance and standard repair procedures are described. Hot links are provided to local electronic copies of manufacturer’s and vendor documentation. Hot links are also provided to MSDS for all chemicals used.