- Home

-

Research Groups

Division Groups

- Artificial Photosynthesis

- Catalysis: Reactivity & Structure

- Electrochemical Energy Storage

- Electron- and Photo-Induced Processes for Molecular Energy Conversion

- Neutrino and Nuclear Chemistry

- Surface Electrochemistry and Electrocatalysis

Associated Groups

- Catalysis for Alternative Fuels Production

- Nanostructured Interfaces for Catalysis

- Structure and Dynamics of Applied Nanomaterials

- People

- Operations

- News

- Events

Catalysis: Reactivity and Structure

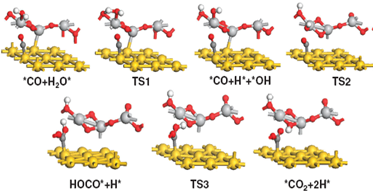

Mechanistic understanding of WGS catalysts from first principles: Au(111) Supported Oxide Nanoparticles

Water-gas

shift (WGS, CO + H2O → H2

+ CO2) is critical to get clean hydrogen from fuel cells and

other industrial applications. A fascinating puzzle has recently emerged:

Au/CeO2 and Au/TiO2 nanomaterials show very efficient

for WGS catalysis. This is remarkable since in bulk form Au, ceria and

titania are not known as WGS catalysts. The nature of the active phase(s) in

these metal/oxide nanocatalysts is unclear at the present time. Is it AuOx,

metallic Au, or an oxide nanoparticle?

To address these questions, coordinated effects have been made from

experiment and theory. Our experimental collaborators have grown and

characterized inverse model catalysts: CeO2 and TiO2

nanoparticles dispersed on a Au(111) template. The experiments show

activities comparable to good WGS catalysts (e.g. Cu(100), Cu(111)).

Theoretical calculations based on DFT are also carried out to understand the

active sites in the oxide/gold catalysts, by probing reaction scenarios on

Au(100) and Au(111) surfaces, a free Ti2O4 cluster,

and a TiO2/Au(111) catalyst model structure. In accordance with

experiment, our calculations show a very high barrier for the dissociation

of water on Au(111) or Au(100) and the formation of very stable formate

species on free TiO2 that prevents the production of H2

and CO2. The model TiO2/Au(111) catalyst

overcomes these bottlenecks: the moderate chemical activity of gold is

coupled to the more reactive TiO2 nanoparticle. The dissociation

of water takes place on the oxide easily, a reaction that extended surfaces

and nanoparticles of Au cannot perform. CO adsorbs on sites of the gold

substrate located nearby (bifunctional catalyst). Then all the subsequent

steps occur at the oxide-metal interface at a reasonable speed. Our results

imply that the high performances of Au/CeO2 and Au/TiO2

nanocatalysts in the WGS rely heavily on the direct participation of

oxide-metal interface.

Water-gas

shift (WGS, CO + H2O → H2

+ CO2) is critical to get clean hydrogen from fuel cells and

other industrial applications. A fascinating puzzle has recently emerged:

Au/CeO2 and Au/TiO2 nanomaterials show very efficient

for WGS catalysis. This is remarkable since in bulk form Au, ceria and

titania are not known as WGS catalysts. The nature of the active phase(s) in

these metal/oxide nanocatalysts is unclear at the present time. Is it AuOx,

metallic Au, or an oxide nanoparticle?

To address these questions, coordinated effects have been made from

experiment and theory. Our experimental collaborators have grown and

characterized inverse model catalysts: CeO2 and TiO2

nanoparticles dispersed on a Au(111) template. The experiments show

activities comparable to good WGS catalysts (e.g. Cu(100), Cu(111)).

Theoretical calculations based on DFT are also carried out to understand the

active sites in the oxide/gold catalysts, by probing reaction scenarios on

Au(100) and Au(111) surfaces, a free Ti2O4 cluster,

and a TiO2/Au(111) catalyst model structure. In accordance with

experiment, our calculations show a very high barrier for the dissociation

of water on Au(111) or Au(100) and the formation of very stable formate

species on free TiO2 that prevents the production of H2

and CO2. The model TiO2/Au(111) catalyst

overcomes these bottlenecks: the moderate chemical activity of gold is

coupled to the more reactive TiO2 nanoparticle. The dissociation

of water takes place on the oxide easily, a reaction that extended surfaces

and nanoparticles of Au cannot perform. CO adsorbs on sites of the gold

substrate located nearby (bifunctional catalyst). Then all the subsequent

steps occur at the oxide-metal interface at a reasonable speed. Our results

imply that the high performances of Au/CeO2 and Au/TiO2

nanocatalysts in the WGS rely heavily on the direct participation of

oxide-metal interface.

Ref. J.A. Rodriguez, S. Ma, P. Liu, J. Hrbek, J. Evans, and M. Perez, Science 318, 1757 (2007).