- Home

-

Research Groups

Division Groups

- Artificial Photosynthesis

- Catalysis: Reactivity & Structure

- Electrochemical Energy Storage

- Electron- and Photo-Induced Processes for Molecular Energy Conversion

- Neutrino and Nuclear Chemistry

- Surface Electrochemistry and Electrocatalysis

Associated Groups

- Catalysis for Alternative Fuels Production

- Nanostructured Interfaces for Catalysis

- Structure and Dynamics of Applied Nanomaterials

- People

- Operations

- News

- Events

Neutrino and Nuclear Chemistry

The NNC group utilizes several analytical instruments, chemical synthesis and production systems, and support facilities to develop and produce cutting edge scintillator materials, tailored specifically to meet the stringent measurement needs of highly sensitive radiation detector systems. Our group has developed capabilities which enable us to reach beyond laboratory scale R&D and have created a unique facility able to support large scale experiments and scientific collaborations.

Scintillator R&D requires the ability to synthesize novel materials and quantify their chemical properties and characterize their radiation response. Our laboratory is well equipped with analytical instrumentation for characterization of material and scintillation properties. Our scintillator production facility is equipped for large scale production of the scintillator materials developed in our lab. The following is a brief description of our analytical instruments, production equipment, and support facilities:

Research Instruments

Shimadzu 1800 -UV-Visible spectrophotometers

The UV-1800 is an advanced high-resolution spectrophotometer utilizing a precision Czerny-Turner optical system. Liquid scintillators are optical materials and this instrument allows us to analyze and understand the materials’ properties by measuring optical parameters. The instrument has different measurement modes to measure several optical properties of samples. Photometric Mode measures the optical absorbance or transmittance, i.e. how clear and transparent the material is at a single wavelength, or at multiple discrete wavelengths of light.

Spectrum Mode measures the absorbance or transmittance for a continuous range of wavelengths and obtains sample spectra using wavelength scanning. The instrument is also used in a quantification mode, in which absorbance spectra are recorded for standard solutions to build a calibration curve which can then be used to calculate the concentration of unknown solutions. The UV-Vis spectrophotometer with either 1 cm or 10 cm pathlength sample cells is one of our workhorse instruments to characterize liquid scintillators.

Shimadzu IRPrestige-21 FTIR spectrometer

Fourier transform infrared (FTIR) spectroscopy is a technique used to obtain the infrared absorption and emission spectra for solid, liquid, or a gaseous material. When an organic compound is subjected to electromagnetic radiation in the infrared frequency range (780 nm to 1000 µm), the absorbed resonant frequencies give the molecules enough energy to allow their bonds to stretch, bend, or rotate more actively.

The resonant frequency depends on the strength of the bond, which in turn depends on the atoms connected by the bond, the type of bond involved, and, to a certain extent, the environment around each bond. Most functional groups have characteristic absorptions in certain frequency ranges. In FTIR spectroscopy these characteristic absorptions are used to identify what functional groups are present in a sample; we can thereby identify the chemical composition and the structural characteristics of organic materials and mixtures thereof.

Liquid scintillators are chemical cocktails consisting of a base solvent scintillator into which two or more organic and inorganic solutes are dissolved. The concentrations of each component are adjusted to obtain the necessary scintillation response and optical characteristics. The presence of impurities and other unwanted chemical species also affect the properties of the scintillator. The FTIR spectrometer is therefore a useful instrument to keep track of the constituents of the liquid scintillators produced in our lab.

Thermo Scientific ARL QUANT’X Energy Dispersive X-ray Fluorescence (EDXRF) Spectrometer/Thermo Scientific Niton XL3 Portable XRF

X-Ray Fluorescence (XRF) analysis is based on the principle that a sample excited by an X-ray beam returns to its ground state by releasing energy in the form of X-rays. Measurement of the energy and intensity of these secondary X-rays provides information about the material’s elemental composition.

X-rays from the instrument’s X-ray tube source excite the atoms of elements in a sample by ejecting inner orbital electrons by a process known as the photoelectric effect. As the excited atoms return to their ground state, they emit fluorescent X-ray photons with energies that are characteristic of each element in the sample.

These X-ray photons are measured by a detector, which produces a spectrum with peaks corresponding to each element present in the sample. The intensity of the analyte peak is proportional to the amount of that element present in the sample. Therefore, the XRF is a great way to quantify the concentration of a certain element in an unknown sample, provided an accurate calibration curve has been prepared by measuring standard samples.

Our group uses the ARL QUANT’X and a Niton XL3 primarily as quantification tools for specific chemical elements (e.g. gadolinium, indium, neodymium, and tellurium, etc.), that we use to prepare metal-loaded liquid scintillator. We also use the XRF for material screening while selecting new materials or for impurity analysis.

QUANTX-EDXRF

Niton XL3 Portable XRF

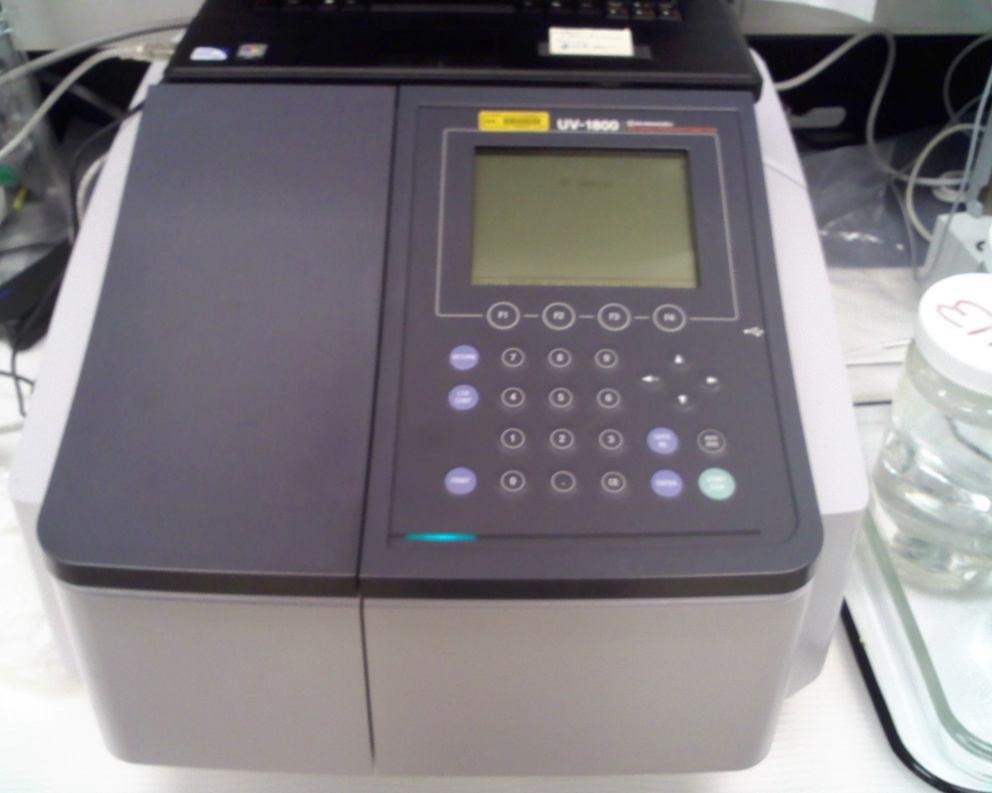

PTI QuantaMaster 8000 Spectrofluorometer

Fluorescence is the property displayed by some atoms and molecules whereby light is absorbed at a wavelength and subsequently emitted as light of longer wavelength after a brief interval, termed the fluorescence lifetime. The fluorescence process is governed by three important events, all of which occur on timescales that are separated by several orders of magnitude: excitation of a susceptible molecule by an incoming photon, vibrational relaxation of excited state electrons to the lowest energy level, and finally the emission of a longer wavelength photon and return of the molecule to the ground state.

The study of the spectral wavelengths that the molecules of a material can absorb to become excited (fluorescence excitation spectra) and the spectral wavelengths the excited molecule emits to return to the ground state (emission spectra) can reveal information regarding the molecular structure of the material.

Since organic liquid scintillators are a mixture of light emitting molecules, each with a characteristic range of emission wavelengths, the PTI fluorometer is used as a tool to characterize the emission response of the scintillator. Future upgrades are planned to modify the instrument to be able to measure the optical anisotropy of the liquid scintillators.

The geometry of the optics in the fluorometer enable the measurement of scattered light at wavelengths beyond intrinsic fluorescence emission of the sample. Since optical scattering is a significant factor causing optical attenuation in the liquid scintillator, it is necessary to characterize this parameter. The fluorometer therefore has a secondary use in measuring the wavelength-dependent optical scattering.

PTI QuantaMaster 8000

PTI QuantaMaster 8000 Experimantal Setup

Zoom

Beckman Coulter LS6500 Multi-purpose Liquid Scintillation Analyzer

The light yield is the number of visible light photons emitted by a liquid scintillator per unit of energy deposited in the scintillator by an ionizing radiation particle. In the case of our organic liquid scintillators, we measure the relative light yield as compared to a well-known organic scintillator such as anthracene or linear alkyl benzene. The light yield of liquid scintillator samples relative to a known scintillator sample is measured with an automatic liquid scintillator counter (Beckman LS6500). The counter is equipped with a 137Cs gamma source, two photomultiplier tubes (PMT) in coincidence mode, and a multichannel analyzer.

The counter performs automatic cyclical measurements of the liquid scintillator and reference scintillator samples over an extended period of typically 70 hours. Each sample is measured for 15 minutes in each cycle during which, 662 keV gamma-rays from the 137Cs source are made incident onto the sample vial and the ionizing energy of the gamma-rays causes the scintillator to emit visible light which is counted by the PMT’s. The output signal of the PMT’s is analyzed and a pulse height histogram is generated. The relative light yield is estimated by comparing the pulse height histograms of the sample and the reference scintillator.

Beckman Coulter LS6500

High Purity Germanium HPGe Compton Suppression Spectrometer

The Compton-suppressed HPGe spectrometer is a highly sensitive gamma-ray spectroscopy system capable of detecting and identifying ultra-low levels of radioactive sources in samples. The spectrometer is used for screening materials and chemicals used for making liquid scintillator precursors to determine the presence of any radioactive impurities.

The spectrometer consists of a HPGe detector encased in a radiopure lead radiation shielding vessel called a “pig” (made from lead produced pre-WW-II to limit background radiation from 137Cs). The intrinsic sensitivity of the HPGe detector is enhanced by not just the lead shield but also an annular veto detector made from BGO, which is a fast, inorganic scintillator.

The veto detector eliminates the signals from any Compton scattered gamma-rays, thereby enhancing the “true” signals form the potentially radioactive impurities in the samples being measured by the HPGe detector. This active suppression of stray radiation signals significantly enhances the sensitivity of the HPGe detector.

HPGe detector setup

PerkinElmer Flexar Ultra-High Performance Liquid Chromatography Mass Spectroscopy (UHPLC-MS) System

UHPLC-MS is a chemistry technique that combines the physical separation capabilities of liquid chromatography with the mass analysis capabilities of mass spectrometry. UHPLC-MS is a powerful technique used for many applications which has very high sensitivity and selectivity. Generally, its application is oriented towards the general detection and potential identification of chemicals in the presence of other chemicals (in a complex mixture).

The technique has both qualitative and quantitative uses. These include identifying unknown compounds, determining the isotopic composition of elements in a molecule, and determining the structure of a compound by observing its fragmentation. Other uses include quantifying the amount of a compound in a sample.

Due to its capabilities listed above, the PerkinElmer Flexar is powerful tool to screen liquid scintillator samples to determine the presence of unwanted and unintentional chemical impurities that may have an adverse effect on the properties of the scintillator.

Liquid Chromatography Mass Spectroscopy (UHPLC-MS) System

LED-pulsed 2-m vertical attenuation system

Good optical transparency is a fundamental requirement of the organic liquid scintillators (LS), and characterizing the transparency of the organic liquid to its own scintillation light is the key parameter to determine the overall sensitivity of the detector. The attenuation of light in a clear liquid scintillator can be characterized by measuring its optical attenuation length, i.e. the minimum distance photon can travel before undergoing an absorption or scattering event.

Optical absorption and scattering parameters measured by UV-Vis and scattering spectrometers can have intrinsic measurement errors that are magnified when the attenuation length is significantly greater than the measurement path length of the spectrometer. Therefore, a standalone photometer with a long pathlength (~2m) was developed in-house to provide measurements of attenuation length much longer than those practically accessible by commercial spectrophotometers.

This 2-meter vertical system measures light transmission at different pathlengths and different wavelengths (with low luminosity LEDs) simultaneously. LEDs of different wavelengths are mounted in precision optical stages coupled with optical fibers to the vertical stainless-steel tube (which has a reflective Teflon inner liner), that can be filled to various heights with scintillator. A PMT mounted below the tube is used to collect the light. The intensity of the transmitted light is compared to that of a reference LED and the resulting ratio is used to estimate the optical attenuation.

LED-pulsed 2-m vertical attenuation system

Karl Fisher titrator (KF)- Mettler Toledo

This instrument uses either coulometric or volumetric titration methods to determine the amount of water of organic liquids in a sealed system. It measures small amounts of moisture accurately in as low as 0.1 microgram of water or below 1% where a sample contains less than 200 micrograms.

The water content in an organic liquid scintillator is an important parameter to monitor since excess water can cause hydrolysis and polymerization or other types of chemical reactions that can adversely affect the stability and optical properties of the scintillator.

Karl Fisher Titrator

KNF Liquiport high-precision liquid-transfer pumps (6x)

We use several of these pumps throughout our lab to transfer liquid to and from various synthesis systems and storage containers. The KNF pumps allow fine control over a wide range of flow rates.

The pumps are manufactured to be compatible with a range of solvents by utilizing Teflon (PTFE) components. The pumps use a reciprocating PTFE diaphragm to generate the driving pressure to transfer the liquid.

KNF Liquiport

ChemGlass Reactor Systems (10L, 50L, and 90L volumes)

Synthesis of the liquid scintillator precursor components is carried out using special glass process reactors. The reactors are made from Type 1, Class A borosilicate glass and have a jacketed design, which allows for temperature-controlled processes. The reaction vessels have multiple inlet ports, a drain valve, a mechanical stirrer with controller, and a thermocouple for temperature monitoring. The reactor vessel is mounted on a custom-made stainless-steel frame with movable wheels that can be locked. The reactors are placed in fume hoods and have secondary containment for spill control.

The process reactors are primarily used for synthesizing or purifying precursor components that are later used in large scale liquid scintillator production. The reactors are also used for producing smaller batches of new scintillator materials for R&D purposes.

The reactor vessels are easy to use and to keep clean, which helps maintain consistency in production. The clear glass structure also helps keep a visual check for quality control during synthesis.

ChemGlass-Reactor-Systems: 10L | 50L | 90L

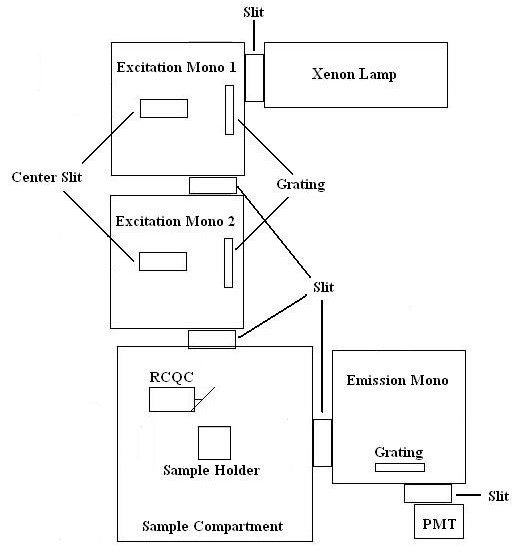

Laboratory Short-Path Vacuum Distillation Systems

The short-path vacuum distillation systems are used to purify a variety of organic solvents and liquid scintillator precursor materials, such as LAB, the carboxylic acid TMHA, surfactants such as TritonX, etc.

The systems use “wipers” to produce a thin film of heated liquid from which evaporation and subsequent condensation onto a cold surface occurs. This method provides the means of isolating impurities from the liquid of interest in a safe and fast manner by

- Enabling distillation at lower heating temperature (e.g. TMHA can be distilled at 50-90°C at 0.001 bar vacuum compared to 160°C at 0.02 bar), this is due to the better vacuum achieved with the aid of an oil diffusion pump backed up by a mechanical vacuum pump.

- Only heating and processing small quantities per unit time of the liquid during the distillation process

- Relying on a shorter run time for the evaporation of the thin liquid film.

The single stage distillation systems can run at 25 liters per 8-hour shift. (This maximum value corresponds to ~35 ml per minute.) The complete system includes the feed vessel, short-path evaporator and internal condenser, computer-controlled heated oil bath, condenser cooling system, cold trap, and vacuum system.

The short-path evaporator, internal condenser, and associated connectors and piping are constructed of high-quality Duran glass; the wiper basket and rotary vacuum pump are constructed of stainless steel. Gaskets are made of Teflon. The systems are mounted on stainless-steel frames.

Of the two systems described above one is manufactured by the InCon Processing Co. in Illinois and the other is manufactured by VTA GmbH.

Miscellaneous Equipment

In addition to the laboratory equipment listed above we also have a number of hot plates, weighing scales, high precision micro-balances, pH meters, thermometers, temperature monitors and controllers, shakers, stirring plates, a centrifuge, drying ovens, UV-lamps, Millipore Ω-18 ultrapure water filtration systems, etc. all of which are vital for the day to day activities of scintillator R&D.

Coming Soon

We are currently in the process of acquiring new lifetime and molecular-size and Zeta potential measurement systems that will enhance our characterization capabilities. These systems would help us further understand the nature of existing liquid scintillators as well as developing new ones.