Advancing Hydrogen R&D

Hydrogen holds promise as an important carbon-free energy carrier of the future, particularly for hard-to-decarbonize industrial and transportation applications. But to realize this vision we need new technologies to produce, store, transport, and utilize hydrogen at scale. Brookhaven scientists are innovating processes, materials, and demonstration capabilities to support the acceleration of hydrogen production and utilization. This work draws on our foundational knowledge and expertise in catalysis, supported by a diverse group of regional and national partners.

Capabilities

- Long-standing programs in “green” hydrogen production, purification/utilization, storage, and deployment in mobile (transportation) or stationary (building) applications.

- Advanced experimental capabilities specifically created for hydrogen research at our user facilities, including x-ray science at the National Synchrotron Light Source II (NSLS-II), electron microscopy at the Center for Functional Nanomaterials (CFN), and theory/data science through our Computational Science Initiative (CSI).

- Surface electrochemistry and electrocatalysis: Developing platinum monolayer electrocatalysts for fuel cell reactions.

- Catalysis for alternative fuels production: Aiming to find replacements for platinum, namely nitrides of earth-abundant metals (EAM), suitable for large-scale hydrogen fuel production by water electrolysis at reduced cost

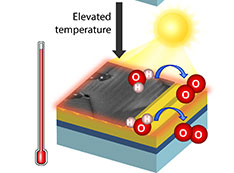

Hydrogen powered by electrocatalysis

Carbon-free hydrogen can be a green energy source when produced by extracting hydrogen from water (H2O) using electricity generated by renewable wind and solar power. Scientists at Brookhaven Lab have pioneered research on novel electrocatalysts that enable these reactions, also known as electrolysis or water splitting. For instance, scientists at Brookhaven are developing low-cost, durable electrocatalysts that avoid the use of expensive platinum group metals currently used in many electrolyzers (electrolysis devices). The goal is to accelerate the scale-up of green hydrogen production.

Brookhaven Lab's Northeast Solar Energy Research Center (NSERC) serves as a solar energy research and test facility for the solar industry. The NSERC includes a solar PV research array for field testing existing or innovative new technologies under actual northeastern weather conditions and is fully instrumented to provide high resolution data for research purposes.

Hydrogen production testbed

Brookhaven Lab is planning a testbed for producing hydrogen via electrolysis using solar energy generated by the Lab’s five-acre solar research array, the 1 Megawatt (MW) Northeast Solar Energy Research Center (NERSC). For the hydrogen testbed (known as DEMO, for H2 design, engineer, materialize, and operationalize), Brookhaven scientists plan to work with industrial partners to test a range of industrial scale systems and run performance and durability evaluations under a wide range of operating conditions. The testbed will enable the performance of electrolyzers to be optimized for seamless coupling to an intermittent solar power resource. In addition, the testbed will permit in-field testing of pre-commercial components and help to optimize the configuration of the renewable power source, the grid, and the electrolyzer to maximize hydrogen production.

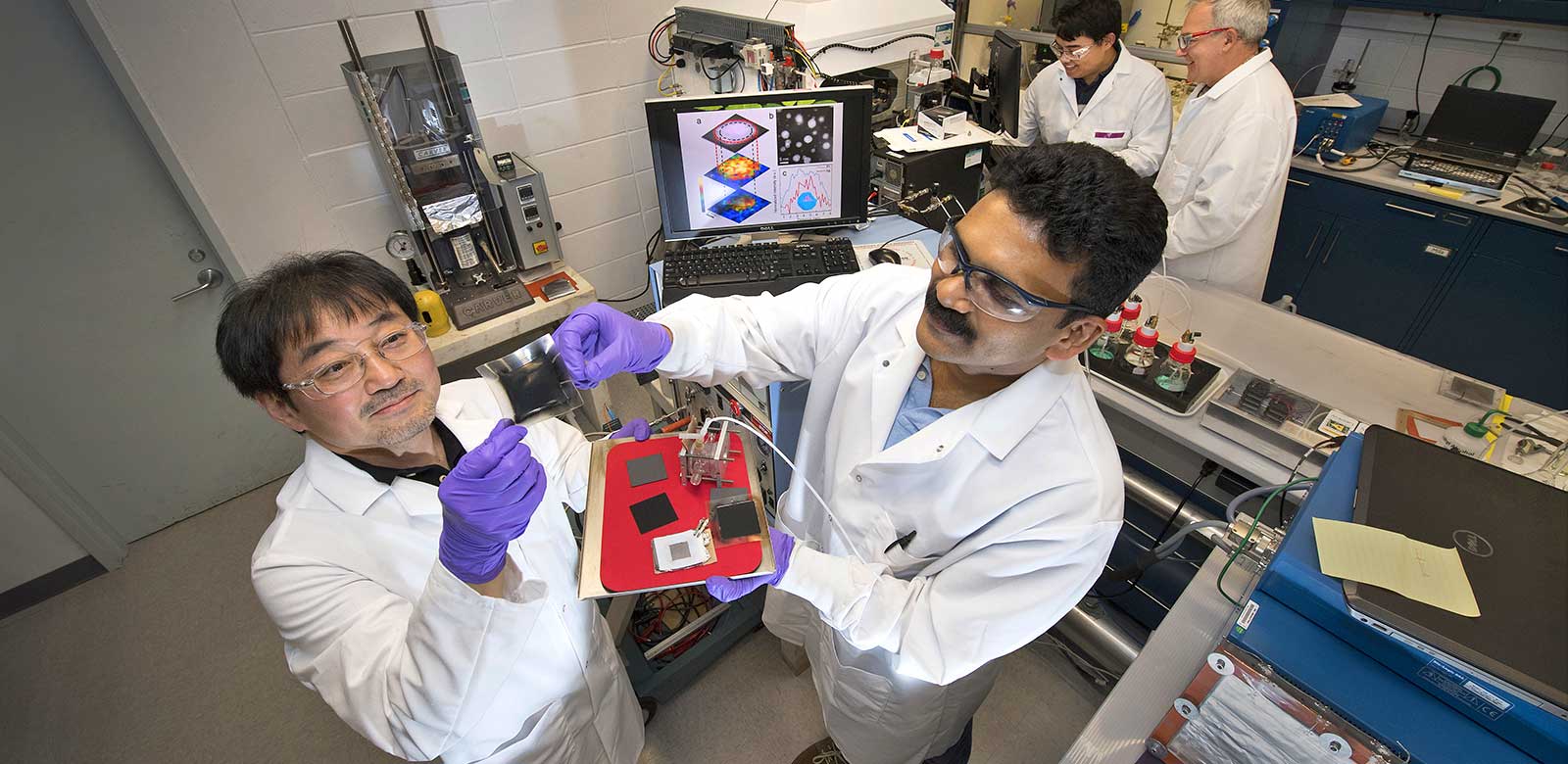

Brookhaven Lab chemists Kotaro Sasaki (left) and Kurian Kuttiyiel with fuel cell catalyst samples.These nitride catalysts are among the materials that Brookhaven will explore through the Million Mile Fuel Cell Truck consortium to develop more durable and efficient fuel cells for heavy-duty vehicles such as trucks.

Hydrogen use in fuel cells

Brookhaven scientists have advanced the use of hydrogen in mobile and stationary applications, including fuel cells for powering transportation vehicles. We work closely with companies interested in licensing or commercializing research applications. For example, Brookhaven scientists developed a single-layer platinum catalyst that reduces the amount of this expensive material needed for powering fuel-cell reactions and advanced fundamental understanding and practical applications for this class of catalyst. Brookhaven also participates in the Million Mile Fuel Cell Truck consortium, which explores and develops more durable and efficient fuel cells for heavy duty vehicles. In addition, through a partnership with the New York State Energy Research and Development Authority (NYSERDA), we’ve received funding to test stationary fuel cells to be used as backup power for data centers.