Recovery Act Pushes High-Field Magnet Development Forward

August 25, 2009

A collaboration of national laboratories, universities, and industry is testing a new material that could help to revolutionize the superconducting magnet field.

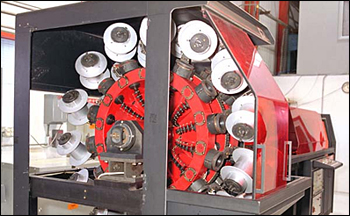

The U.S. Department of Energy is providing $4 million in Recovery Act funds over the next two years to the Very High Field Superconducting Magnet Collaboration to develop a bismuth-based material that may allow scientists to create high-field superconducting magnets that could achieve more than twice the strength of existing magnets. Fermi National Accelerator Laboratory will manage $1.5 million of the new funds and has already started making cable to test the new material. Brookhaven staff, led by physicist and program manager Arup Ghosh, will test these cables at a specialized facility in the Lab’s Superconducting Magnet Division. So far, Brookhaven has received $55,000 in stimulus funds for the project, with more expected next year.

Brookhaven’s Relativistic Heavy Ion Collider (RHIC), Fermilab’s Tevatron, and the Large Hadron Collider (LHC) at CERN all use superconducting magnets made of niobium-titanium to steer their beams of particles. Of that bunch, the LHC’s magnets can achieve the highest field – 8 Tesla. But recent tests on alternative materials, such as niobium-tin, reached a magnetic field of 13 Tesla.

The development of high-field magnets that can exceed 50 Tesla could provide a path forward for a possible muon collider.

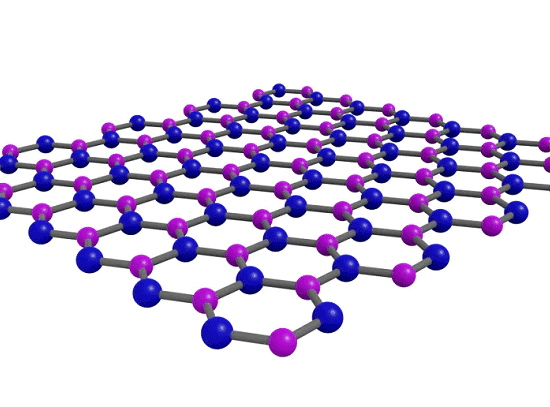

Led by spokesperson David Larbalestier of the National High Field Magnet Lab at Florida State University, collaboration members believe that BSCCO2212 is the answer. But because it has a completely different structure than niobium-titanium, it comes with a new set of challenges, namely that it breaks very easily.

“In order to turn it into a superconductor, we heat the BSCCO2212 up to 800 degrees,” said Fermilab physicist Alvin Tollestrup. “The trouble is that it becomes more or less a ceramic. If you bend it, it breaks.”

In the project’s first phase, Fermilab will purchase the bismuth-based material from U.S. vendors to conduct cabling and coil studies. Collaboration members will research the material’s properties in detail and determine how much they can stretch it and whether they can make it into cables.

In addition to Fermilab, Florida State, and Brookhaven, other members of the collaboration include Lawrence Berkeley National Laboratory, Los Alamos National Laboratory, the National Institute of Standards and Technology, and Texas A&M University.

Collaboration members also will partner with businesses to encourage industrial fabrication of high-field magnets, an effort that could result in cutting edge technologies for other applications.

“Superconducting magnets have been one of the main keys for enabling technology,” Tollestrup said. “There is no doubt that there are uses both in high-energy physics and areas of industry and medicine that will require high-field magnets.”

Elizabeth Clements of Fermilab contributed to this story.

2009-1393 | INT/EXT | Newsroom