New Microscope Construction Builds New York State Business Opportunities

March 12, 2010

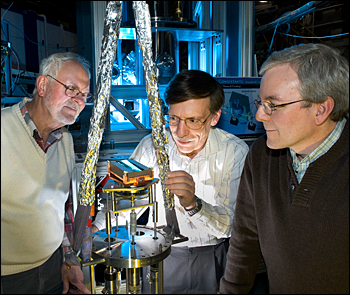

Physicists Peter Takacs (left), Dan Fischer, and Steven Hulbert install a custom-made synchrotron mirror, manufactured by the upstate optics company Optimax, for a new XPS microscope at the NSLS.

A local optics company, Optimax, has been successful in learning to make synchrotron mirrors — creating a new niche for the New York business and for the U.S.

This work came about during the development of a new, high-tech x-ray photoelectron spectroscopy (XPS) microscope prototype being conducted by a methods and instrumentation development team (MIDT) at the NSLS. The MIDT is led by The National Institute of Standards and Technology (NIST) and is a collaborative effort with the NIST Small Business Innovation Research (SBIR)-funded company called R. Browning Consultants.

Scientists employ XPS microscopes to study materials that are used to make nanotechnologies such as computer chips and solar cells. The new microscope will have a 1000-fold higher resolution than the technology currently available and will be the world’s most advanced XPS microscope when combined with Brookhaven’s National Synchrotron Light Source II (NSLS-II).

In order to reach these new technological heights, the microscope requires a high-intensity laser-like x-ray beam to be focused precisely onto a small region where nanomaterials are inserted. While “breathing life” into the prototype, Dan Fischer, the NIST physicist who is leading the project, found that the x-ray beam couldn’t be aimed in the exact spot required for the microscope’s design. He decided that a new toroidal mirror was needed to focus the x-ray beam in the proper location.

The simple solution quickly became difficult for the team after they learned that there are no U.S. companies that manufacture these synchrotron mirrors. Peter Takacs, a physicist in Brookhaven’s Instrumentation Division, presented the problem to Optimax, which specializes in the rapid fabrication of optics for devices such as cameras and telescopes.

“Optimax has specialized machines that are capable of making the grazing incidence aspheric mirror that we need, but the optics they normally make are much different than this mirror,” said Takacs. “We wanted to convince them to take on the project since there are currently no U.S. suppliers of these synchrotron mirrors.”

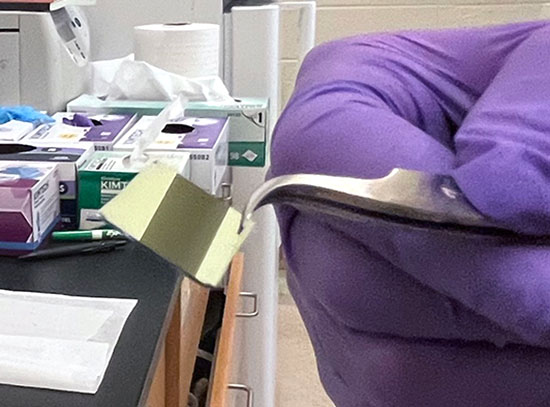

After visiting the NSLS to understand the technological requirements and several months of reviewing specification drawings, the Optimax team figured out a process to fabricate the 3 x 4.5-inch mirror.

“This was actually a very challenging project,” said Joseph Spilman, the sales engineer from Optimax who helped determine whether the company should take on the new niche product. “Brookhaven needed a toroidal mirror, which is a free-form shape that is completely different than what most optics companies in America are used to making.”

The company applied its machine expertise and knowledge of optics together with the methodological advice from the MIDT and successfully manufactured the mirror to the precise parameters provided to them by the MIDT and Steven Hulbert, a vacuum ultra-violet (VUV) optics expert and head of the NSLS Experimental Systems Division.

“Manufacturing the mirror helped us develop new capabilities in an area that we are excited to build upon, “ said Spilman. “We would like to strategically align ourselves, and our capabilities, to be a good supplier of synchrotron optics for Brookhaven.”

The project opened the way for Optimax and other local companies with similar capabilities to manufacture synchrotron optics that could meet the specialized needs of the numerous synchrotrons located around the world, in addition to Brookhaven’s NSLS and NSLS-II.

“We couldn’t be happier that Optimax took a chance on this project and was successful,” said Takacs. “It means that we and other synchrotrons all over the U.S. and the world can now use them as a resource and go back for additional mirrors.”

“This was a great opportunity for government to reach out to small, local companies to help them begin working in technical fields and become a partner for producing synchrotron optics in the U.S.,” said Fischer.

New York State is a major center for optics fabrication in the U.S., encompassing many small businesses that supply the majority of the optics industry needs. The team hopes to inspire additional local optics companies to take up the niche.

“The entire world sees New York State as one of two or three centers for optics, photonics, and imaging work,” says Thomas Battley, executive director of New York Photonics, a non-profit dedicated to the growth of the photonics, optics, and imaging industry of New York State. “There is no optics or photonics problem that couldn’t be solved by a local company, and there is no reason that Brookhaven should have to look anywhere else for solutions to its photonics and optics needs. This project with Optimax is a great example of that.”

“My vision is to eventually partner with New York state trade organizations and try to develop the next generation of local optical fabrication technicians,” said Takacs.

“This project has turned out to be a great success,” said NSLS Chair Chi-Chang Kao. “We are looking forward to working with the team to bring this new capability online as soon as possible. Moreover, the partnership with Optimax is an excellent example of how BNL and New York companies can work together to meet Brookhaven’s research needs and create new in-state business opportunities.”

2010-1630 | INT/EXT | Newsroom