Painting Nanopatterns with Molecular Bottlebrushes

January 22, 2019

What is the scientific achievement?

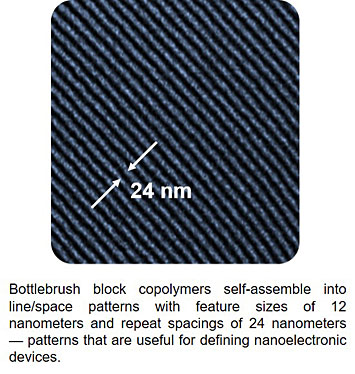

In this work, MIT scientists worked with CFN members to study the process by which silicon-containing polymers with a ‘bottlebrush’ molecular architecture can spontaneously form ordered patterns with nanoscale dimensions. Thin-films of the bottlebrush materials self-assembled into line/space patterns with repeat distances of about 24 nanometers.

Why does this achievement matter?

This bottlebrush material forms high quality nanopatterns over large, micron-sized areas. Moreover, its ordering can be directed using topographic templates. Because the bottlebrush contains silicon, the material can be used as a mask for subsequent nanofabrication steps. Taken together, these make the bottlebrush well-suited for use in fabricating nanoelectronic devices.

What are the details?

Self-assembling materials spontaneously form desired nanostructures. Molecules are designed so as to organize themselves into desired nanoscale shapes, which thereby bypasses the need for laborious fabrication of nanostructures. While polymer-based self-assembling materials are well-known, their use in patterning applications such as the lithography used to make microchips has so far remained elusive. This research investigates a new kind of self-assembling polymer. This new material combines two interesting features: (1) a ‘bottlebrush’ architecture—where a long backbone has many ‘bristles’ emerging from it—which allows it to form nano-stripes in a well controlled way; (2) one of the self-organized domains is silicon-containing, which is ideal for eventual nanopatterning/microelectronics applications. To demonstrate the potential for such electronics applications, this material was ordered using `directed self-assembly,’ where topographic features made using conventional lithography guide the organization of the nanostripes. This combination of conventional patterning and nanoscale self-assembly paves the way towards facile fabrication of future nanoelectronics.

CFN Capabilities:

The CFN/NSLS-II partner instrument at NSLS-II was used to measure the assembly process during vapor exposure.

Publication Reference

L. –C. Cheng, K. R. Gadelrab, K. Kawamoto, K. G. Yager, J. A. Johnson, A. Alexander-Katz, and C. A. Ross, Templated Self-assembly of a PS-branch-PDMS Bottlebrush Copolymer, Nano Letters 18, 4360 (2018).

DOI: 10.1021/acs.nanolett.8b01389

Acknowledgement of Support

The support of NSF DMR-1606911, NSF CHE-1629358, and AFOSR FA9550-14-1-0292 is gratefully acknowledged. Shared experimental facilities of CMSE, an NSF MRSEC at MIT under award NSF1419807, and the NanoStructures Laboratory were used. This research used resources of the Center for Functional Nanomaterials and the National Synchrotron Light Source II, which are U.S. DOE Office of Science Facilities, at Brookhaven National Laboratory under Contract No. DE-SC0012704. We also thank the U.S. DOE, Office of Basic Energy Sciences, Division of Materials Science and Engineering for partial support of this work through award No. #ER46919 (simulations and analysis).

2019-14347 | INT/EXT | Newsroom