Industrially Favorable Fabrication of Electrodes for High-Performance Supercapacitors

November 20, 2015

What Is The Scientific Achievement?

enlarge

enlarge

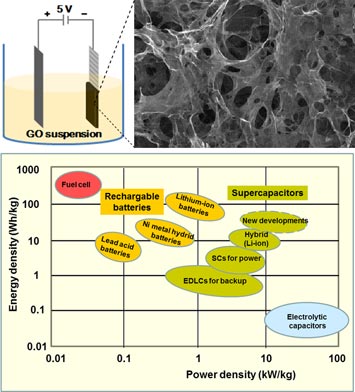

Top Left) Schematic illustration of the electrophoretic fabrication of RGO hydrogel electrodes. Top Right) SEM image of a freeze-dried RGO hydrogel electrode. Bottom) The favorable power and energy densities of supercapacitors make them desirable for myriad applications, such as energy storage for automobiles, trains, and other transportation systems.

Reduced graphene oxide (RGO) hydrogel, the assembly of reduced graphene sheets into three-dimensional porous structures, has emerged as a promising candidate for use as a high-performance supercapacitor electrode material. Entrapped water in the RGO hydrogel acts as spacer, preventing the restacking of the RGO sheets; this yields a highly open and porous structure that creates continuous ion transport networks and allows electrolyte solutions to access to the surface of individual RGO sheets easily. Further, this allows RGO-based hydrogel supercapacitors to operate at ultrafast charge-discharge rates. However, RGO hydrogels have very low mechanical strength due to their large water content, which is easily altered during electrode processing. In this work, we have developed a one-step electrodeposition approach toward the preparation of electrodeposited RGO hydrogels (ERGO) on stainless steel meshes, which can be used directly as high-performance supercapacitor electrodes without post-treatment. The ERGO exhibited excellent specific capacitance, rate performance, and cycling stability. More interestingly, a >50% enhancement of the specific capacitance % was achieved by using HQ as redox-active electrolyte. In total, our results have demonstrated the great potential of ERGO hydrogels as a promising electrode material for high-performance supercapacitors.

Why Does This Matter?

This one-step, scalable technique to prepare RGO hydrogel electrodes for supercapacitors can be used with a wide variety of materials and substrates and can be incorporated into existing industrial electrochemical manufacturing protocols.

What Are The Details?

CFN Capabilities: CFN’s Electrophoretic Deposition Facility was used to synthesize the RGO suspension and to fabricate the RGO hydrogel-based electrodes. The Electrochemical Characterization Facility was used to characterize the supercapacitor performance. The scanning electron microscopy was performed in the Electron Microscopy Facility.

Publication Reference

Facile electrodeposition of reduced graphene oxide hydrogels for high-performance supercapacitors

Viet Hung Pham,a Tesfaye Gebre,b James H. Dickerson,a

a Center for Functional Nanomaterials, Brookhaven National Laboratory, Upton, NY 11973

b Department of Physics, Florida A&M University, Tallahassee, Florida 32307, USA.

Nanoscale 7, 5947 (2015)

Acknowledgement of Support:

This work was performed at the Center for Functional Nanomaterials, Brookhaven National Laboratory, which is supported by the U.S. Department of Energy, Office of Basic Energy Sciences, under Contract no. DE-AC02-98CH10886.

2015-6197 | INT/EXT | Newsroom