Meet Christine Ali: Military War Veteran and Chemical Engineer

From setting up fuel stations for the U.S. Army in Iraq to monitoring complex gas-delivery systems at NSLS-II, Christine Ali brings a wealth of experience and passion to science

April 17, 2020

enlarge

enlarge

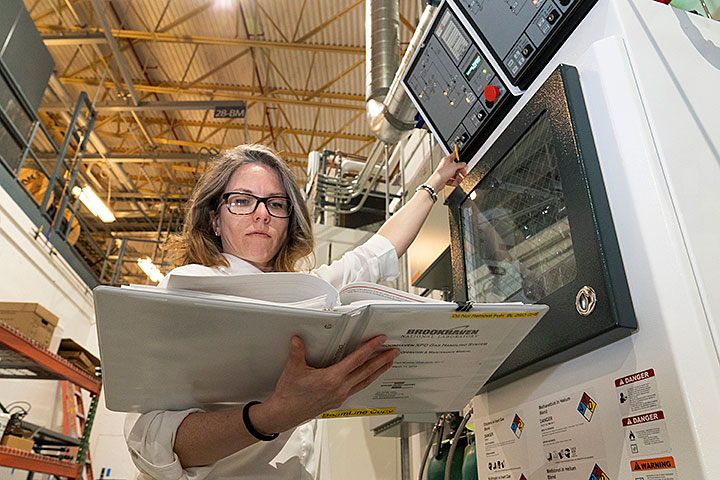

Christine Ali oversees the needs of all the laboratories at Brookhaven's National Synchrotron Light Source II, manages two large multipurpose chemistry labs, and is the system expert for several gas-handling systems that enable cutting-edge research at this facility.

Christine Ali discovered the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory on a drive-by. She and her husband, both U.S. Army veterans of Operation Iraqi Freedom, were on the highway in search of a home on Long Island. She saw a sign for the Lab and Googled it.

“I see Nobel Prizes, the incredible range of research, and I say, ‘They do science there; it's amazing! I have to work there!’ And even though it had nothing to do with what I was doing at the time, I knew I wanted to be a part of that.”

Now she oversees the needs of all the laboratories at Brookhaven’s National Synchrotron Light Source II (NSLS-II), manages two large labs, and is the system expert for several gas-handling systems at this DOE Office of Science user facility. Based on procedures and protocols she’s written and systems she’s helped to develop, implement, and test, she is working on the design of new gas-handling capabilities.

“These are huge, complex systems designed to introduce ultra-high-purity compressed gas under a variety of gas-temperature-pressure-controlled conditions for studies of catalysts and battery materials. We are pioneering a whole new type of sample environment, and ideally it will bring us to new types of batteries, or new types of catalysts,” she said.

When fully implemented, these systems will make NSLS-II one of only a handful of synchrotron facilities in the world with such complex gas-handling capabilities.

Operation Iraqi Freedom

Ali is no stranger to huge, complex systems. As a petroleum supply specialist in the Army, she drove 5,000-gallon tanker trucks filled with jet fuel or diesel, and set up mobile fueling stations.

“We had to set up temporary systems that were like gas stations to fill trucks, tanks, planes, and helicopters—any type of aviation or ground vehicles that we used overseas in Iraq—and then break it down and pack it away,” she said.

She’d joined the military just after graduating from high school in a small town outside Buffalo, New York, when a military recruiter showed up at her door hoping to convince her brothers to sign up.

Slideshow from Christine (Huber) Ali’s time serving with the U.S. Army’s 424th Quartermaster Company out of Shoreham, NY, at the Balad Air Base and working on fuel convoys with the 1st Infantry Division in Iraq. One photo shows Christine with fellow soldier Zaheer Ali, who is now her husband. Hover over image to reveal slideshow controls.

“I wasn't sure really what I wanted to do or what direction I wanted to go in. And, to me, if something's not a challenge, I don't want to do it because it becomes very boring. I figured the military would be really challenging, and it would keep me on track,” she said. “I was like the easiest recruit that recruiter ever had!” (Her brothers did not join.)

Given the option of working in public affairs, which would involve a lot of community outreach and interaction, or the mobile fuel-station gig, she chose the latter, where she’d work with just the soldiers in her unit.

“I wasn't a people person,” she said.

She did meet one special person, before even shipping out to Iraq.

“I got deployed in 2003 for 545 days as part of the second wave of soldiers to serve in Operation Iraqi Freedom. I started out attached to a unit here in Shoreham, where I met my husband. We’ve been together ever since—all through the war. When we came back, I finished out my contract with the military in Buffalo and then moved to New York City.”

It took some time for her to get her footing. “It’s not the best when you come back from a war zone and try to readjust back into civilian life,” she noted. “When I got my head back on my shoulders, I decided I wanted to do something in science.”

Discovering science

While living in the Bronx, she started studying “criminalistics” at John Jay College of Criminal Justice, which she thought would lead to a career in crime-scene investigation. But she learned, after enrolling, that she would first need to become a police officer (with more training at the police academy) to pursue this career.

Fortunately, while interning in the evidence unit of the medical examiner’s office in Manhattan, she discovered a more scientific side to evidence—the biochemical details.

enlarge

enlarge

The gas-handling systems Ali has implemented at NSLS-II can be operated via an HMI touchscreen interface.

“I like evidence. It tells a story that people just don't see, especially when we look at the fine details. That's what convinced me I was studying the wrong thing and I switched to toxicology.”

After completing her bachelor’s degree, she worked in clinical and forensic toxicology labs analyzing biological specimens such as blood, hair, urine, and saliva, looking for traces of alcohol and drugs as evidence for court cases. It was interesting at first, but then started to become too routine. “It’s not anything like what they display on TV,” she said.

When she learned about a roadblock to potential advancement—a New York State requirement for an additional 800-hour certification—she said, “I basically hit this wall: either I do the training, or I'm stuck where I am, or I look for something else.”

That’s when she saw the sign for Brookhaven Lab, at Exit 68 on the Long Island Expressway.

From six-month position to new career

Ali came to Brookhaven at the start of January 2018 by way of a temporary position, helping to manage two NSLS-II laboratories focused on structural biology and studies of soft matter. The job was to assure safe operations of the lab space and equipment, train Lab staff and guest users and enforce rules, keep required supplies fully stocked, test new lab capabilities, and so on.

It was only a six-month appointment, and a career change. “Were we willing to throw all of our apples into this once-in-a-lifetime possibility?” she asked.

Her husband pointed to her leadership qualities and military experience and said, “You can do it.”

“I swung and I got it,” said Ali.

Almost as soon as she started, NSLS-II Research Operations Manager Michael Buckley, her supervisor, recognized her potential to do even more challenging work. He encouraged her to apply for an open position as an NSLS-II chemical engineer. Ali jumped at the chance to help bring the facility’s gas-handling system into full operation.

Gas system up and running

“I was so nervous,” she recalls. “I felt like an imposter. I just have a bachelor's degree and all these people have doctorates,” she thought.

“But after learning the system components and mechanics, and how they relate to other beamline experimental instrumentation, it became easier,” she said. “I’m writing procedures and policies and conducting training on how the gas system works, and still being able to oversee the individuals that run the laboratories.”

The gas-delivery system is expected to be used by a wide set of scientists studying energy-related materials, including the catalysts that speed up chemical reactions relevant to every aspect of modern industry.

enlarge

enlarge

Electrochemical sensors detect and monitor for toxic and combustible gas leaks. If a leak is detected, these sensors will automatically trigger alarms and place the gas-system into a safe state to prevent accidental exposure.

“One major advantage of synchrotron x-ray measurements like those they do at NSLS-II is the ability to study the atomic-level structure of materials under changing conditions, often to simulate real-world operating conditions,” said Ali. These studies could lead to discoveries about how to make more-efficient catalysts for cleaner-operating chemical production of fuels and other products.

The biggest challenge has been to develop and implement the administrative and engineering controls for using potentially hazardous gases.

“We’ve installed a wide range of sensors and developed special procedures to provide the level of safety required to handle hazardous gases such as hydrogen (highly flammable), nitric oxides (toxic), ammonia (corrosive), and others, while also allowing operations with nonhazardous, inert gases such as nitrogen, argon, and helium,” Ali said.

To ensure safe experimental operation, Ali takes into account the hazards of the gases, the concentration of the mixtures, the experimental flow rates, the sample set-up, and ensures that any connections made downstream of the sample have been sufficiently tightened to prevent gas leaks or incorrect flow rates.

“Sniffers” monitor gas at the point of use, constantly sampling air around the sample; other sensors monitor the air flow that vents gases away from the experimental station; additional sensors detect if any gas is leaking or approaching a certain limit that will shut the entire system down.

“All sensors are wired and monitored by Brookhaven’s Fire Rescue Group, who will respond if an alarm is triggered,” Ali said.

enlarge

enlarge

The gas handling system on the inboard side of NSLS-II's beamline 28ID. Multiple valves and monitoring devices ensure safe operations during research on catalysts and other energy-related materials.

Ali also thinks about the role that heat or the material composition of the sample may play in experimental operating conditions or results. There could be “decomposition hazards”— changes caused by chemical interactions between a gas and a catalyst or other material under study.

“I’ve said to the scientists, ‘You're responsible for your scientific experiment. I'm responsible for getting everything that you use for that scientific experiment, to make sure it's functioning, operating, and in proper order to do your science,’” she said.

Building skills and relationships

Clearly, the details can be daunting, and Ali tracks everything in a notebook she carries with her at all times. She walks through the labs and takes notes every morning, then figures out what needs to be fixed, ordered, or implemented as she interacts with lots of people—and then more people as she calls vendors and manufacturers and works out contracts for maintaining systems to keep things running smoothly.

“There’s lots of coordination with many different departments both inside and outside Brookhaven Lab,” she said. “It’s the complete opposite end of the spectrum from where I was people-wise at the age of 18!”

She credits Michael Buckley and several training programs—including Stony Brook University’s Women in STEM Leadership program—with helping her develop the skills she’s needed to succeed.

“I thrive under challenges, and in stressful situations, I’m very calm. I'm very detail oriented, very structure- and policy-oriented. I’m also very direct. I tell it like it is without beating around the bush. It goes back to my core values—the things that were established in the military—honesty, integrity, and loyalty.”

She’s also very disciplined when it comes to blowing off steam: She goes to the gym every day at lunchtime. And after being bombarded with requests and demands at work, she enjoys time with her husband and two dogs, tending her own vegetable garden and incorporating her harvest into cooking at home.

It may have taken some time for Ali to find something that fit her personality, but she seems quite at home, now.

“Here I get a whole spectrum of things that I thoroughly enjoy. I get to interact with students in the structural biology lab. I'm still a part of managing the laboratories. And I support people working on protein structures and how they function down to the molecular level, how atoms vibrate, how their energy changes the molecules. Or at other beamlines, where they diffract x-rays to tell you what form things are in, whether they’re crystalline or some other state. And then batteries—they’re doing experiments to learn whether lithium metal will make batteries last longer for your vehicles, cell phone, and laptop,” she said. “It’s all super cool.”

NSLS-II is operated with funds from the DOE Office of Science.

Brookhaven National Laboratory is supported by the U.S. Department of Energy’s Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit https://www.energy.gov/science/

Follow @BrookhavenLab on Twitter or find us on Facebook

2020-17053 | INT/EXT | Newsroom