Unraveling The Fundamental Principles of Eutectic Solidification With Real-Time, Nanoscale Imaging

Understanding how to control microstructure during solidification can help achieve desirable properties like strength and ductility

September 19, 2024

By Patricia DeLacey

enlarge

enlarge

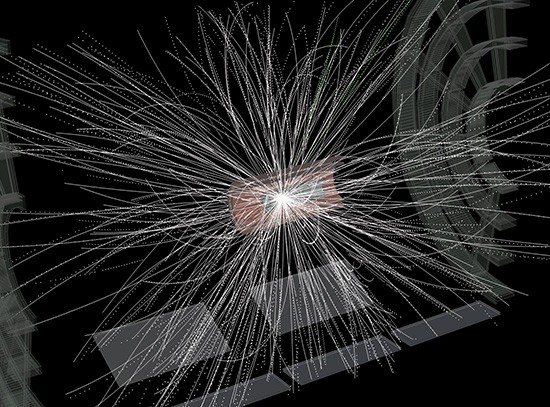

A 3D reconstruction of an Al3Ni crystal splitting upon increasing the velocity in directional solidification. Credit: Shahani Laboratory.

Editor’s note: The following article was originally issued by the University of Michigan (UMich). Beamline scientist Xianghui Xiao collaborated with researchers from UMich to study the solidification mechanism of an aluminum-nickel alloy. The team used a state-of-art transmission X-ray microscope at the Full Field X-ray Imaging (FXI) beamline at the National Synchrotron Light Source II, a U.S. Department of Energy (DOE) Office of Science User Facility at DOE’s Brookhaven National Laboratory and they combined real-time radiographic imaging within a limited angle range with high-resolution tomographic imaging in an innovative way. The data collected from these techniques helped the team unveil the mechanism controlling the formation of different microstructures as solids self-assemble. What they have learned could lead to the ability to tune properties of materials such as strength and flexibility for a wide range of applications. Xiao was able to host this student project with sponsorship from DOE’s Science Graduate Student Research program. For more information on Brookhaven’s role in this research, contact Denise Yazak (dyazak@bnl.gov, 631-344-6371).

During eutectic solidification, a mixture of two or more solids self-assemble, forming composite microstructures ranging from ordered layers to intricate maze-like patterns that underlie properties like tensile strength or ductility. Up to this point, researchers have not understood what conditions drive eutectics to form certain patterns, which is critical for designing reproducible next-generation eutectic composites.

Capturing real-time solidification of an aluminum-nickel eutectic alloy (Al-Al3Ni) in nanometer resolution revealed that increasing the solidification velocity shifts microstructure from irregular and faceted to regular and rounded, according to a study led by University of Michigan researchers recently published in Acta Materialia.

Leveraging this new understanding of eutectic formation will help tune microstructure for the material class used in high-temperature components in turbines or reactors.

“I have always been captivated by patterns in nature—like snowflakes, where no two are ever identical. This fascination with how such seemingly simple processes can give rise to endlessly rich, complex, and unique structures drives me to explore the underlying principles behind them,” said Ashwin Shahani, an associate professor of materials science and engineering and chemical engineering at U-M and senior author of the study.

“In materials science, the same kind of wonder applies: how do small changes in conditions lead to dramatically different microstructures?”

To better understand how eutectic microstructures form, the research team designed a new in-situ furnace at the synchrotron beamline for directional solidification—a technique where the crystal growth from the liquid to solid phase is oriented in a specific direction. The apparatus permits precise control over the solidification processing space, enabling detailed study of pattern formation during eutectic solidification.

To correlate the nanoscale observations with microscale phenomena, the researchers combined two visualization techniques. Optical microscopy captured solidification over large space- and time-scales while synchrotron transmission x-ray microscopy provided nanoscale insights. The latter was conducted at the full-field X-ray imaging beamline 18-ID at Brookhaven National Laboratory’s National Synchrotron Light Source II.

With this, they directly observed the interaction between the liquid, aluminum (Al) and nickel aluminide (Al3Ni) crystals during solidification under different conditions. The growth rate of Al3Ni compared to Al—called the degree of coupling—determined the shape of the solid microstructures left behind. For example, when solidifying at lower velocities, the leading tips of the Al3Ni grow ahead of Al, causing irregular, faceted growth. At high solidification velocities, Al3Ni and Al grow at the same rate, resulting in rounded, regular growth.

In a casting, solidification velocity depends on several factors, including the thermal conductivity of the melt and the rate of heat extraction.

“Our first-of-its-kind experiments and real-time observations help to explain the great diversity of patterns produced by the solidification of eutectics containing stiff, intermetallic phases. These insights are essential to inform and validate simulations of materials synthesis,” said Paul Chao, a doctoral graduate of materials science and engineering at U-M, who spent a full year in 2022 as a resident researcher embedded at the synchrotron beamline, and first author of the study.

“Our experiments serve as an example of how excellent mentorship at the University of Michigan, partnership with Brookhaven National Laboratory, and international collaboration are critical to cutting-edge research that can resolve fundamental scientific enigmas.”

This finding is of broad relevance to a wide spectrum of eutectic systems including those that are metallic, semi-metallic and organic.

“Manipulating these patterns is more than just a technical pursuit—it is a way to unravel fundamental principles and apply them in meaningful ways, from improving the strength of materials to pioneering new approaches in materials design,” said Shahani.

This research was supported in part by the National Science Foundation CAREER program (1847855), Air Force Office of Scientific Research United States (FA9550-21-1-0260) and the Department of Energy (DE-SC0012704; 2021 Office of Science Graduate Student Research Award).

Full citation: “From irregular to regular eutectic growth in the Al-Al3Ni system: in situ observations during directional solidification,” Paul Chao, Shanmukha Kiran Aramanda, Xianghui Xiao, Sabine Bottin-Rousseau, Silvère Akamatsu, and Ashwin J. Shahani, Acta Materialia (2024). DOI: 10.1016/j.actamat.2024.120314

Open access version available on Arxiv.

2024-22089 | INT/EXT | Newsroom