- Home

-

Divisions

Energy Systems Division

- Grid Modernization and Security

- Energy Conversion

- Geothermal Materials

Energy Storage Division

- In-situ and Operando Analysis

- Vehicle Technologies

- Grid-level Storage

- Center for Mesoscale Transport Properties

- Long Island Solar Farm

- NSERC

- People

- Org Chart

Energy Systems Division

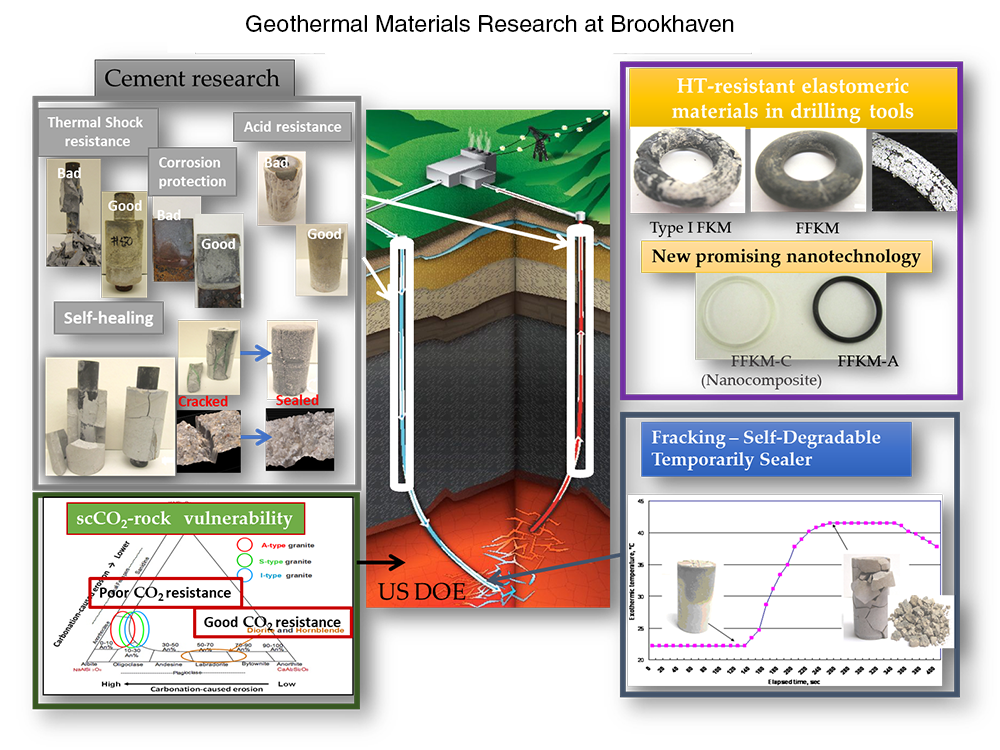

Geothermal Materials Research

Our Geothermal Materials research focuses on the development of new materials that can withstand the extreme conditions found in geothermal wells and facilitate the use of geothermal reservoirs for power generation and storage as an “always on”, renewable solution for energy diversification worldwide.

The U.S. Department of Energy’s Geothermal Technology Office (GTO) conducted a rigorous technical analysis (GeoVision) that evaluated future geothermal deployment opportunities and outlined necessary actions for success of geothermal energy in the GeoVision roadmap. Our research directly addresses GeoVision roadmap actions that call for durable materials to improve well-completion technology for better well life cycles, improved zonal-isolation techniques, and development of geothermal hybrids allowing pairing of geothermal energy with other energy sources, e.g. solar.

Capabilities

Brookhaven scientists have world-class capabilities to conduct research in the development of new geothermal well materials. A state-of-the-art testing laboratory is available on site for formulating and evaluating new materials developed. The laboratory contains equipment for sample preparation (autoclaves, ovens, mixers), testing and characterization (mechanical Instron testing, thermogravimetric analyzer, differential scanning and isothermal calorimeters, optical 3-d microscope, X-ray diffractometer, FTIR spectroscope, µEDX, carbon analyzer, and AC/DC electrochemical corrosion testing, contact angle, thermal conductivity measuring equipment).

-

Tatiana Pyatina

Energy Systems Division

Interdisciplinary Science Department

(631) 344-8646, tpyatina@bnl.gov

Research Areas

TEST-CEM

Sustainable geothermal well cement for challenging thermo-mechanical conditions. TEST-CEM aims to improve the technology used in the development of geothermal solutions that harnesses the earth’s energy in a safe, reliable, and cost-effective approach to help address the need for renewable energy sources to combat climate change.

Self-degradable sealer for EGS applications

The objective of this project is to develop temporary sealers possessing self-degradable properties in terms of conversion of bulk cement into fine crumbles under the hydrothermal environment at temperature >150oC.

Anti-corrosion and Anti-fouling coatings

The objective of this project is to develop the processing and synthesis technologies of coating materials providing corrosion-, abrasive wear-, and scale fouling-mitigations of carbon steel (CS)-based -heat exchangers, -wellhead pipes, and -steam separators, and aluminum (Al)-finned-air-cooling condensers, in geothermal power plants.

Underground energy storage system

The aim of the project is to facilitate combining energy production (solar, wind) and energy storage, to smooth out fluctuations in energy production caused by changing weather and time of a day, reduce demand charges, and provide clean energy to the grid when it is most valuable, through development of innovative cementitious materials that enable economical and resilient natural energy storage.

Multifunctional, self-healing, self-re-adhering cementitious composite

In recent years, with the support of DOE GTO, BNL developed a superheat- and thermal shock resistant cement (TSRC) as a non-Ordinary Portland Cement system (non-OPC).

HT resistant elastomeric materials in drilling tools

Brookhaven Lab in collaboration with Sandia National Laboratory and with the support from DOE GTO conducted a study evaluating the degradation of six elastomeric polymers used for O-rings: EPDM, FEPM, type I- and II-FKM, and FSR in five different geothermal environments at 300oC:

CO2- as a working fluid

Based on the excellent heat transport properties of supercritical carbon dioxide (scCO2) compared with that of water, scCO2 is very attractive for use as a geo-working fluid in Enhanced Geothermal Systems (EGS). However, one serious concern raised for scCO2 geofluid is its reactivity with rock formations.