- Home

-

Divisions

Energy Systems Division

- Grid Modernization and Security

- Energy Conversion

- Geothermal Materials

Energy Storage Division

- In-situ and Operando Analysis

- Vehicle Technologies

- Grid-level Storage

- Center for Mesoscale Transport Properties

- Long Island Solar Farm

- NSERC

- People

- Org Chart

Energy Systems Division

Geothermal Materials Group

Self-degradable sealer for EGS applications

A critical operation in constructing EGS is the construction of the hydrothermal reservoir in an impermeable rock formation at temperatures >200oC located at 3-10 km below the surface. In this operation, water is pumped down from the injection well to stimulate the hot rock formation. This hydraulic stimulation initiates the opening of existing fractures. After forming the reservoir consisting of a permeable fracture network, a production well is installed into this network. During the wellbore construction in strongly fractured formations, drilling operations often encounter severe or complete loss of the drilling fluid into the formation (lost circulation) at temperatures between 70o and 110oC. Fluid circulation cools down the well (circulating temperature). After the well drilling is completed and fluid circulation stops, the well temperature rises to that of the natural reservoir (static temperature).

To deal with the lost circulation problem, the lost circulation zones must be sealed or plugged with appropriate materials. Once this problem is resolved, the drilling operation can resume and continue until the wellbore structure is completed. Next, all sealing and plugging materials must disintegrate at elevated static temperature (>150oC) in order to facilitate heat recovery through the fracture network. Thus, the objective of this project is to develop temporary sealers possessing self-degradable properties in terms of conversion of bulk cement into fine crumbles under the hydrothermal environment at temperature >150oC.

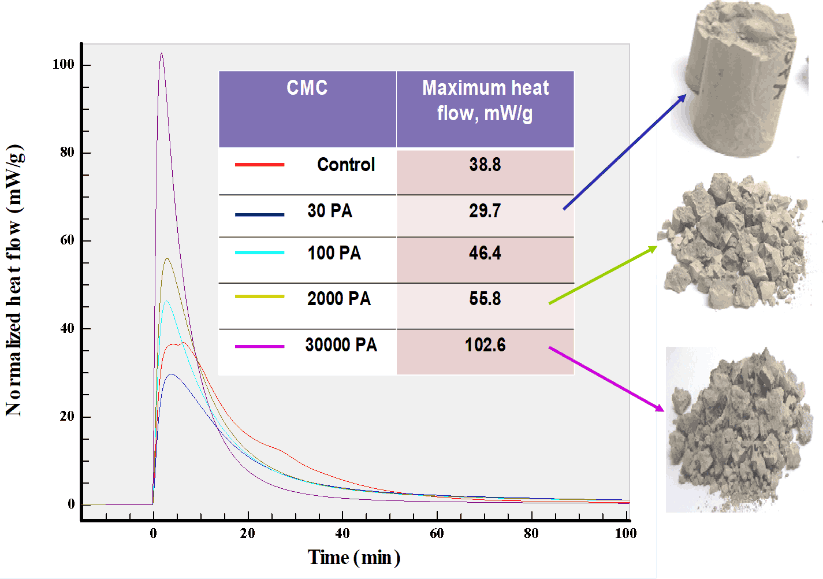

Self-degradation performance vs. in-situ heat flow rates generated in cements modified with different CMCs after it meets water.

Thus far, two approaches to achieve this project goal were made by alkali oxidation of specific cement additives for cement-based sealers: One was the utilization of alkali-oxidized sodium carboxymethyl cellulose (CMC) as a water-catalyzed self-degradation promoter; the other was polyvinyl alcohol (PVA) flakes as an in-situ gel→ sol phase transition-initiated self-degradation promoter. For the former, the degradation pathway was due to the CO2(gas) evolution generated in highly exothermic reactions between water and salt reactants derived from oxidized CMC. For the latter, oxidized PVA at 85oC forms PVA gel phase in cement. When hydrothermal temperature increases to >150oC this phase transforms to easily dispersible sol phase in cement partially leaching out of the cement matrix and leading to the cement self-degradation.

-

Tatiana Pyatina

Energy Systems Division

Interdisciplinary Science Department

(631) 344-8646, tpyatina@bnl.gov