Brookhaven Lab Chemists Win R&D 100 Award for Fuel Cell Research

June 20, 2012

enlarge

enlarge

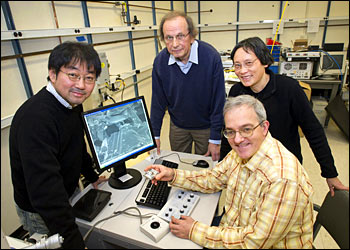

(From left) Brookhaven National Laboratory chemists Kotaro Sasaki, Radoslav Adzic, Jia Wang, and Miomir Vukmirovic work on the recently licensed electrocatalysts using a new electron microscope in their laboratory.

Chemist Radoslav Adzic and his research team at the U.S. Department of Energy’s Brookhaven National Laboratory have won a 2012 R&D 100 award from R&D Magazine for their work designing durable electrocatalysts for use in fuel cells. Their work could make future fuel cell vehicles more reliable and economical.

The R&D 100 awards recognize the 100 most technologically significant products introduced into the marketplace over the past year. Brookhaven scientists have previously won R&D 100 awards for excellence in a diverse array of fields, including imaging techniques, cancer detection, and microscopes for nanomaterials.

“We are deeply honored to be receiving this prestigious award,” said Adzic. “We hope it will lead to even greater interest in this type of catalyst.”

Adzic collaborated on the award-winning research with Brookhaven scientists Jia Wang, Miomir Vukmirovic, and Kotaro Sasaki. On Nov. 1, they will be honored alongside the rest of the R&D 100 winners at a banquet in Orlando, FL.

“Congratulations to this year's R&D 100 award winners,” said Energy Secretary Steven Chu. “The research and development at the Department of Energy’s laboratories continues to help the nation meet our energy challenges, strengthen our national security and improve our economic competitiveness.”

Fuel cells convert chemical energy into electricity, using a catalyst for the necessary oxidation and reduction reactions. Platinum is the most efficient electrocatalyst for fuel cells, but it is also expensive and unstable.

To help reduce the cost and improve stability, the Brookhaven team developed an electrocatalyst that uses a very small amount of platinum, a one atom thick nanoshell surrounding a palladium or palladium alloy nanoparticle core. Proper design of the alloy core both improves the catalytic activity and the durability of the platinum monolayer nanoshell.

“The core-shell structure of this catalyst is amenable to tailoring its properties,” Adzic said.

Since platinum in automotive fuel cells tends to corrode during the voltage cycling of stop-and-go driving, the improved durability through proper design of the palladium alloy core is an important improvement. The core keeps the platinum stable and further increases the fuel cell’s resilience.

The resulting catalyst is durable, highly active, and significantly less expensive than other catalysts, containing just one-tenth as much as platinum as a conventional catalyst. With platinum hovering at prices approaching $50,000 a kilogram, this advance represents a significant potential cost savings for fuel cell manufacturers.

Adzic’s group is now working on finding alternative materials for the palladium core to make electrocatalysts even more affordable.

Earlier this year, the team’s invention was licensed for use in electric vehicles by N.E. Chemcat Corporation, Japan’s leading catalyst manufacturer.

Adzic’s research is funded by the DOE Office of Energy Efficiency and Renewable Energy and the DOE Office of Science, with some Cooperative Research and Development (CRADA) funding from industrial partners.

2012-11428 | INT/EXT | Newsroom