Toshifumi Sugama Honored for Contributions to Geothermal Industry

Recognized for developing several materials that make geothermal energy accessible and reduce reliance on fossil fuels

October 4, 2023

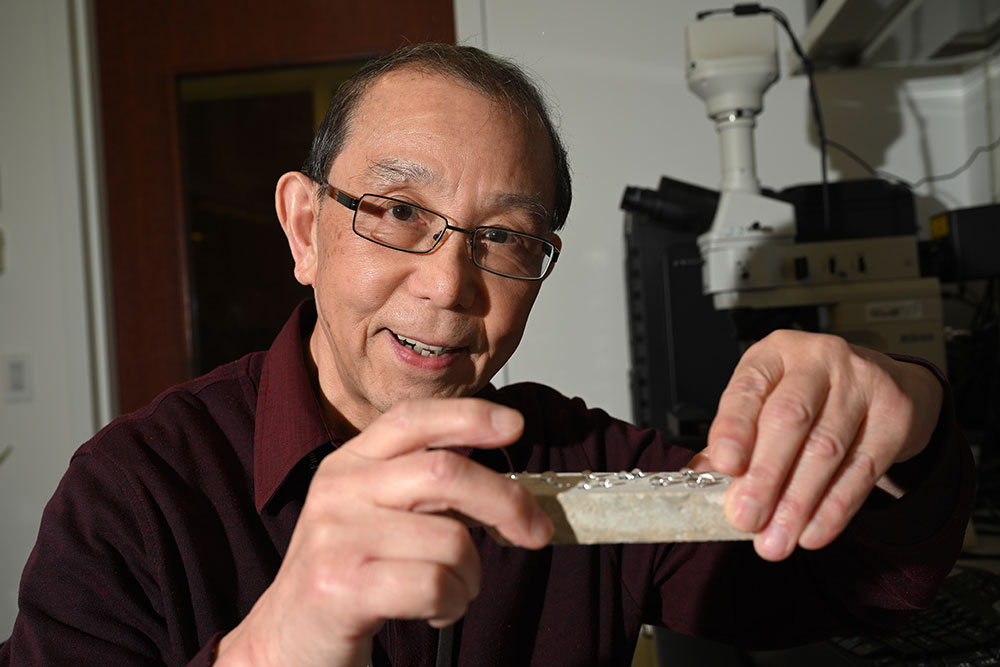

UPTON, NY—Toshifumi Sugama—a chemist in the Interdisciplinary Science Department at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory who designs, develops, and evaluates materials for geothermal wells—received the Outstanding Research Award from Geothermal Rising, a non-profit organization advocating for the advancement of geothermal energy around the world. Recipients of the Outstanding Research Award are recognized for their excellence in research and potential impact on the geothermal industry.

Sugama’s award was announced on Oct. 3 at the 2023 Geothermal Rising Conference in Reno, Nevada. He was honored for his nearly five decades of work in the geothermal energy field, which seeks to generate electricity from heat trapped deep underground.

“I was very happy to learn that I had been selected as the recipient for this award and I would like to express my sincere gratitude to the geothermal community for the recognition of my work,” said Sugama, who joined Brookhaven Lab in 1978.

Temperatures at the center of the Earth can exceed 9,000 degrees Fahrenheit—largely due to the heat remaining from Earth’s formation and the immense amounts of energy released from the radioactive decay of molten rock at Earth’s core. Though this heat is generated nearly 2,000 miles below Earth’s surface, it radiates out from the center of the planet and warms the layers of rock lying between the planet’s core and its surface. In some parts of the world, the heat can rise to the surface as lava or get released as hot water through geysers and hot springs. Sugama’s work, however, has focused on tapping into the heat trapped in rocks deep below the surface.

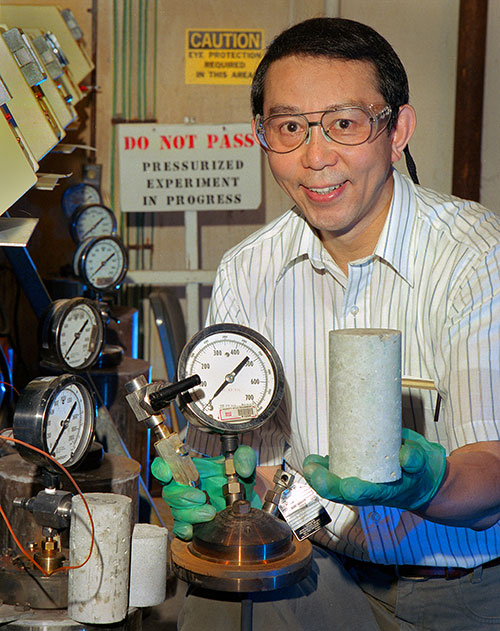

Sugama develops materials that allow geothermal engineers to access Earth’s underground heat using geothermal wells, cylindrical structures typically made up of concentric layers of carbon-steel casing and cement. These pipe-like structures are designed to pump water—heated by the surrounding rocks to more than 400 degrees Fahrenheit—to the surface so that its steam can spin an electricity-generating turbine. Once the heat is extracted, the water is pumped back into the ground to be used again, making this a sustainable energy source.

A key challenge of geothermal energy, however, is that all the infrastructure needs to withstand the harsh conditions created by the hot, wet, and chemically corrosive environment. That’s where Sugama’s decades of contributions to the industry come in.

Cements, Coatings, and Sealants

Most recently, he and Tatiana Pyatina, a Brookhaven Lab materials scientist, developed a lightweight, water-repelling cement (published in Materials in 2021). The water repellency lowers the thermal conductivity of the new cement to nearly one-third that of traditional cement. This minimizes the amount of heat lost to the cement as the hot fluid is recovered from deep wells. This cement also protects the geothermal wells from thermal shock—a rapid and drastic change in temperature that could cause the carbon-steel structures to expand or shrink. Similar to the way water can seep into asphalt, freeze, and expand to cause cracks or potholes in roads, expansion or shrinkage of the geothermal well casing can create cracks in the structures, rendering them useless. Sugama and Pyatina’s insulating cement prevents that from happening.

“Our new technology is just one of Toshi’s legendary contributions to the industry,” said Pyatina. “He has been creating award-winning materials for decades.”

One of Sugama’s most significant commercial innovations is ThermaLock Cement—the only commercial cement designed for geothermal wells with high carbon dioxide (CO2) content. CO2 is common in geothermal fields because this gas is released from the molten underground rocks. The gas remains dissolved in the fluid carrying heat from the rocks until it boils out with the steam that spins the turbine. Constant exposure to CO2 degrades traditional cement because of a chemical reaction called carbonation. To prevent this carbonation and the resulting corrosion, Sugama created zeolite and calcium phosphate minerals that make up ThermaLock Cement by combining fly ash, calcium aluminate, and sodium polyphosphate. This innovation—which was commercialized by Halliburton and won a Research and Development (R&D) 100 Award in 2000—has an expected 20-year service life.

Sugama has also developed a polyphenylene sulfide (PPS) coating for heat-exchanger tubes. The coating prevents corrosion, enhances heat conductivity, and even has the self-healing ability to fill in microscopic cracks that result from physical wear. In contrast to the six-month lifespan of its competitors, this coating can endure 20 years of harsh geothermal conditions. Sugama and Curran International (formerly Curran & Sons) commercialized the PPS coating as CurraLon, which earned them an R&D 100 Award in 2002.

In addition, Sugama improved the efficiency of geothermal-well drilling with a self-degradable sealing material that plugs or seals cracks in surrounding rocks. This sealant reduces the cost of the drilling process by preventing the loss of fluid used to cool and lubricate the drill, which could otherwise seep into the cracks. Once drilling is complete, the sealer self-degrades so that heat-exchanging fluid can flow through the rocks and carry absorbed heat to the well.

Broader Impacts

Sugama’s innovations have had impacts far beyond the geothermal industry. His ThermaLock Cement, for example, is also used to protect infrastructure when drilling for oil and gas. ThermaLock can even remediate soil by trapping contaminants and preventing them from seeping into groundwater or getting carried away by rain or melted snow. His coatings have been used in seawater-desalination, water-treatment, and air conditioning facilities, all of which experience harsh and corrosive conditions like those found in geothermal wells. Manufacturers have also used Sugama’s coatings to protect vehicle bodies, ships, helicopters, and aircraft engines. Sugama and Pyatina’s new cement has potential applications in the construction industry, where its water-repellant properties could help protect buildings from ice, snow, and rain damage.

“Toshi is incredibly creative and continuously coming up with ideas for new materials that have unique properties,” remarked Pyatina.

“We are delighted that Toshi is receiving this special honor for his important contributions to geothermal energy,” said Amy Marschilok, manager of the energy storage and energy systems divisions in the Interdisciplinary Science Department. “We are fortunate to have him as a member of our department and look forward to his next advances in the field including contributions to a new Energy Earthshot Research Center (EERC) focused on materials for Enhanced Geothermal Systems.”

Sugama completed a Ph.D. in chemistry in 1975 at Denk University in Tokyo, Japan. He joined Brookhaven Lab three years later and has served as the principal investigator on almost every project funded by the DOE’s Geothermal Technologies Office. He received a Brookhaven Lab Science & Technology Award in 2001 and was named a Battelle “Distinguished Inventor” in 2003. Sugama has also received two additional R&D 100 Awards in 1988 and 1999 for a zinc-phosphate coating that reduces corrosion of steel and an asbestos-digesting foam. Sugama has over 200 publications in the geothermal materials field and holds 15 patents.

Brookhaven National Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit science.energy.gov.

Follow @BrookhavenLab on social media. Find us on Instagram, LinkedIn, Twitter, and Facebook.

2023-21430 | INT/EXT | Newsroom