High-performance, Earth-friendly Materials for Geothermal Wells

New DOE-funded center seeks to cut costs and improve carbon footprint of cement composites and other materials used in extreme geothermal environments

September 29, 2023

enlarge

enlarge

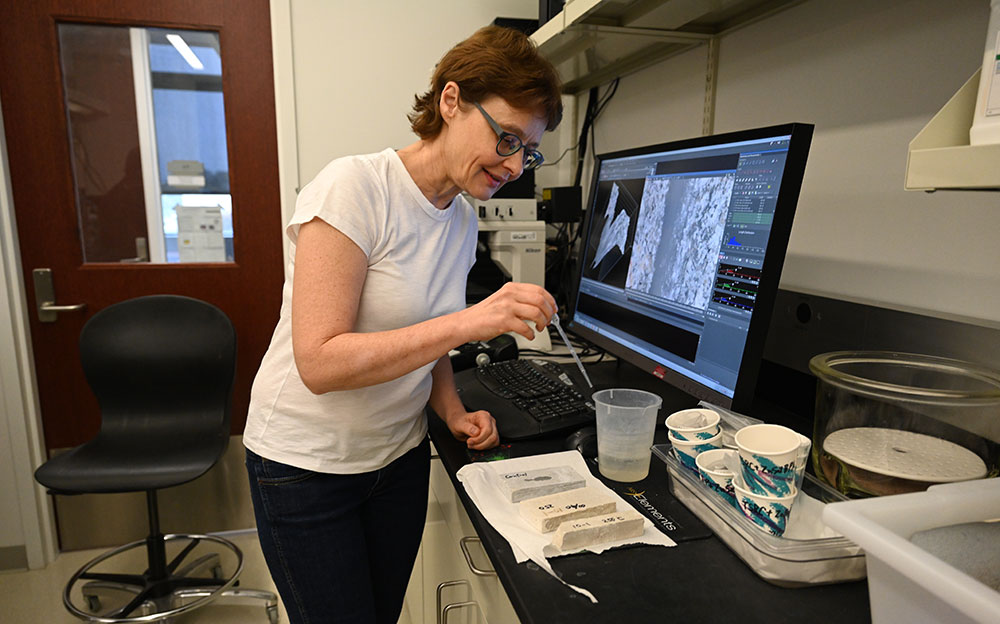

Brookhaven National Laboratory materials scientist Tatiana Pyatina will lead a newly funded DOE Energy Earthshot Research Center aimed at developing sustainable materials for geothermal wells.

UPTON, NY—The U.S. Department of Energy (DOE) has announced $19 million in funding over four years for a new research center focused on exploring the chemical and mechanical properties of cement composites and other materials used in enhanced geothermal systems (EGS). The “Center for Coupled Chemo-Mechanics of Cementitious Composites for EGS” (C4M)—one of 11 Energy Earthshot Research Centers (EERCs) just announced by DOE as part of its Energy Earthshots™ Initiative—will be located in the Interdisciplinary Science Department at DOE’s Brookhaven National Laboratory. Research there and at partner institutions will inform the design of Earth-friendly varieties of cement composites, coatings, and other barriers designed to protect geothermal wells. The ultimate goal is to expand the use of this abundant, sustainable form of energy.

“Our Energy Earthshots are game-changing endeavors to unleash the technologies of the clean energy transition and make them accessible, affordable, and abundant,” said U.S. Secretary of Energy Jennifer M. Granholm. “The Energy Earthshot Research Centers and the related work happening on college campuses around the country will be instrumental in developing the clean energy and decarbonization solutions we need to establish a 100% clean grid and beat climate change.”

Brookhaven Lab materials scientist Tatiana Pyatina, who leads the geothermal materials research effort at Brookhaven Lab and will direct the new C4M EERC, said, “Geothermal energy has the potential to transform abundant heat trapped deep underground into gigawatts of electricity for powering millions of American homes. It is renewable, has a small geographical footprint, and, unlike other green energies [e.g., wind and solar], is available around-the-clock.”

enlarge

enlarge

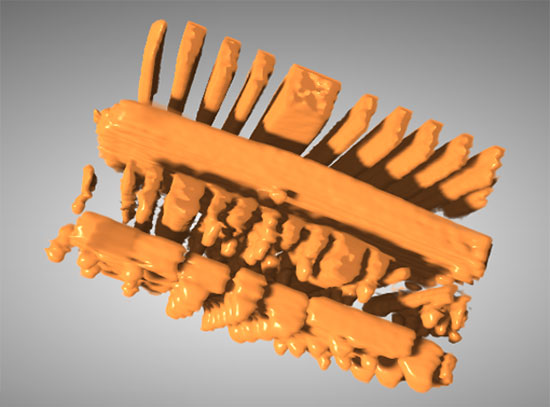

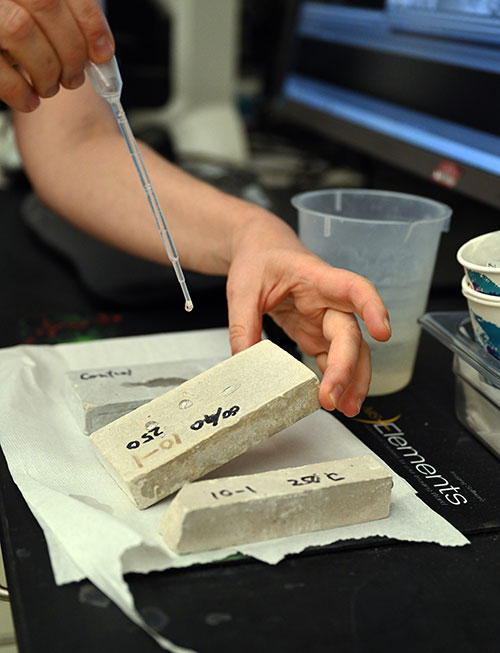

Among the materials the C4M scientists will explore are water-repellent cement composites that help insulate and protect geothermal well infrastructure.

But there are a few sticking points: The materials used to construct the wells—including cement composites that support and insulate the pipelike metal casings that carry Earth-heated fluids from subterranean depths to the surface—must withstand extreme temperatures and corrosive conditions and last for many years. Enhanced geothermal systems, which force more fluid than is naturally present through hot underground rocks to increase the extraction of heat, experience even greater thermo-mechanical stresses. Such stringent materials requirements can drive up construction costs.

In addition, the cement currently used in well-supporting composites is an extreme carbon dioxide (CO2) emitter. Almost a pound of the heat-trapping gas is released for every pound of cement produced—through cement-making chemical reactions and the use of fossil fuels to power the process.

“To realize geothermal energy’s potential, it is therefore essential to rationally design cost-effective, sustainable well-construction materials with a net-zero CO2 footprint,” Pyatina said.

To achieve that goal, the C4M team will conduct extensive studies of the chemical and mechanical properties of new forms of cementitious composite materials. Their goals are to understand the chemical changes that take place in these materials under high temperature and pressure so they can design reliable and durable composites for use in the extremely challenging underground environments. By quantifying the effects of these chemical changes on materials’ performance, they will learn to control the solidification and transformations of these materials so they can be deployed successfully and economically in well construction and operation.

“This work will build on a long history of award-winning research at Brookhaven Lab on materials for sustainable energy applications, including geothermal energy,” Pyatina said. “Our hope is that this research will achieve our goal of developing net-zero CO2 materials that will cut the cost of enhanced geothermal systems by 90% by 2035.”

Amy Marschilok, the energy systems and energy storage division manager of the Interdisciplinary Science Department, noted, “To meet our Nation’s energy goals we need new approaches to harness green energy and release it on demand. The new C4M EERC epitomizes the Interdisciplinary Science Department mission, leveraging Brookhaven Lab’s expertise across the innovation cycle from fundamental materials science to functional energy systems. I look forward to significant advances under Tatiana’s leadership.”

New material needs

In the process of cement production, limestone (calcium carbonate) and other materials are heated to very high temperatures in cement kilns. The high heat triggers a chemical reaction that decomposes the limestone, transforming the calcium carbonate and other ingredients into the compounds that ultimately make up cement powder. The limestone decomposition reaction and the heating that drives it (if powered by fossil fuels) release CO2. To avoid these CO2 emissions, the C4M team will be exploring the use of alternate minerals, possibly even the mud used to drill the wells, which would form its own cement in place.

To ensure well durability, they’ll be seeking to identify materials with geologically stable mineral phases. They will also investigate the use of inorganic coatings that make the pipe-like well casings more resistant to high temperatures and aggressive environments. Some coatings may protect the metal casings so well that cement would no longer be needed.

The team will use both laboratory experiments and computational modeling to elucidate and predict the performance of these new cements and composite materials from the atomic to the macroscopic scale, and for a time span ranging from seconds to years. They expect to use information identified through these studies and the use of artificial intelligence and high-performance computing to design advanced materials with long durability for geothermal applications.

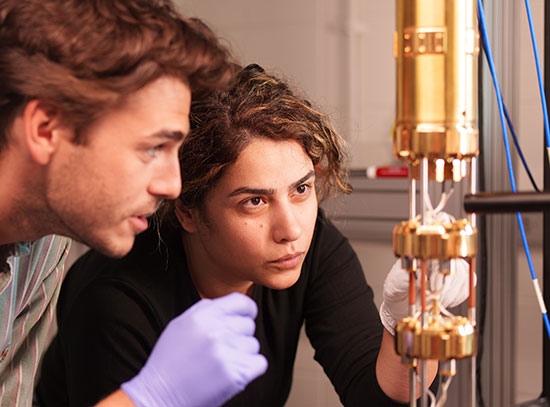

“We have assembled a multi-disciplinary team of leading researchers with complementary expertise,” Pyatina said, noting that the team will leverage expertise and DOE Office of Science user facilities at Brookhaven—including the National Synchrotron Light Source II (NSLS-II) and Center for Functional Nanomaterials (CFN)—as well as at partner institutions, including the Advanced Light Source at DOE’s Lawrence Berkley National Laboratory. Additional partners include DOE’s Sandia National Laboratory, DOE’s Lawrence Livermore National Laboratory, DOE’s Los Alamos National Laboratory, and four universities: University of Texas at Austin (a minority-serving institution), Cornell University, University of Illinois Urbana-Champaign, and Princeton University.

“Through this Center, an incredibly talented team has been assembled to develop the fundamental understanding of the materials needed to push back the pressure and temperature boundaries of geothermal power production,” said Thomas Butcher, a research engineer who leads the energy conversion group in Brookhaven Lab’s Interdisciplinary Science Department. “Each member has been leading research in this area for a long time, but this project will allow them to focus on this important challenge in a truly collaborative way.”

Another group of Brookhaven Lab scientists will participate as partners in one of the other Energy Earthshot Research Centers. That center—“Degradation Reactions in Electrothermal Energy Storage (DEGREES)”—will be led by DOE’s National Renewable Energy Laboratory (NREL). James Wishart, Simerjeet Gill, and Yu-chen (Karen) Chen-Wiegart, staff scientists at Brookhaven, will be partners in this center. They will explore the interactions of molten salts (used here as heat transfer fluids) with thermal energy storage materials and investigate how contact with molten salt affects the thermal materials' stability and performance over time. This research will make use of multimodal x-ray synchrotron techniques at NSLS-II and will include studies on samples brought to NSLS-II from other partner institutions.

Brookhaven National Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit science.energy.gov.

Follow @BrookhavenLab on social media. Find us on Instagram, LinkedIn, Twitter, and Facebook.

2023-21485 | INT/EXT | Newsroom