Microwaving New Materials

Reeja Jayan has made a breakthrough in our understanding of how microwaves affect materials chemistry, laying the groundwork for tailor-made ceramic materials with new electronic, thermal, and mechanical properties.

September 4, 2020

The following news release was originally issued by Carnegie Mellon University. The story describes how researchers investigated the in situ growth of thin films samples using microwave synthesis. The researchers leveraged the highly specialized experimental setup at the X-ray Powder Diffraction (XPD) beamline to watch the reaction occur using x-ray pair distribution function analysis. The XPD beamline is part of the materials characterization suite at the National Synchrotron Light Source II (NSLS-II), a U.S. Department of Energy (DOE) Office of Science User Facility located at DOE's Brookhaven National Laboratory. For more information about Brookhaven's role in this research, contact Cara Laasch, laasch@bnl.gov.

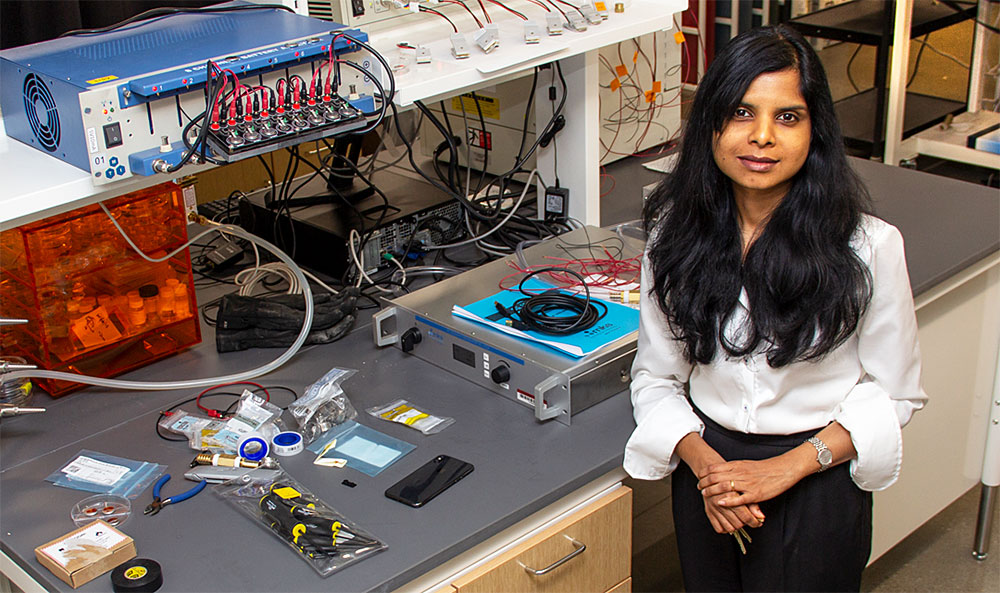

Microwave ovens are the mainstay of cooking appliances in our homes. Five years ago, when Reeja Jayan was a new professor at Carnegie Mellon University, she was intrigued by the idea of using microwaves to grow materials. She and other researchers had shown that microwave radiation enabled temperature crystallization and growth of ceramic oxides. Exactly how microwaves did this was not well understood, and this mystery inspired Jayan to reengineer a $30 microwave oven so she could investigate the dynamics effects of microwave radiation on the growth of materials.

enlarge

enlarge

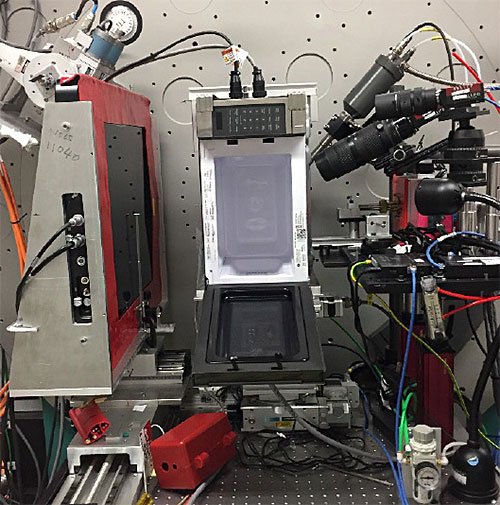

If you look carefully in the center of this photo, you will see the $30 microwave oven that Reeja Jayan reengineered to start her experiments. (Source: Reeja Jayan)

Today, Jayan, who is now an associate professor of mechanical engineering, has made a breakthrough in our understanding of how microwaves affect materials chemistry. She and her student Nathan Nakamura exposed tin oxide (a ceramic) to 2.45 GHz microwave radiation and figured out how to monitor (in situ) atomic structural changes as they occurred. This discovery is important because she demonstrated that microwaves affected the tin oxide’s oxygen sublattice via distortions introduced in the local atomic structure. Such distortions do not occur during conventional materials synthesis (where energy is directly applied as heat).

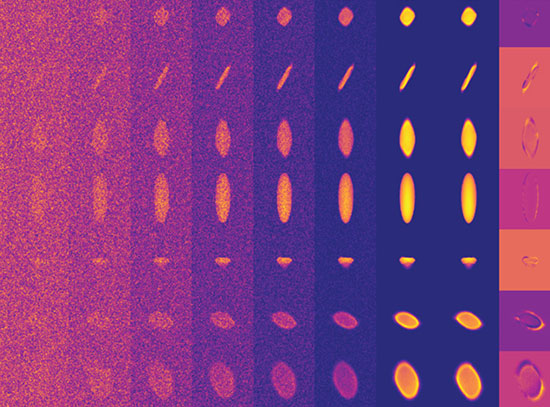

Unlike prior studies, which suffered from the inability to monitor structural changes while the microwaves were applied, Jayan developed novel tools (a custom-designed microwave reactor enabling in-situ synchrotron x-ray scattering) for studying these dynamic, field-driven changes in local atomic structure as they happen. By revealing the dynamics of how microwaves affect specific chemical bonds during the synthesis, Jayan is laying the groundwork for tailor-made ceramic materials with new electronic, thermal, and mechanical properties.

enlarge

enlarge

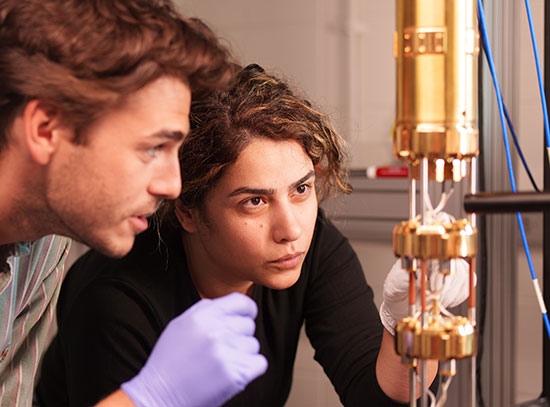

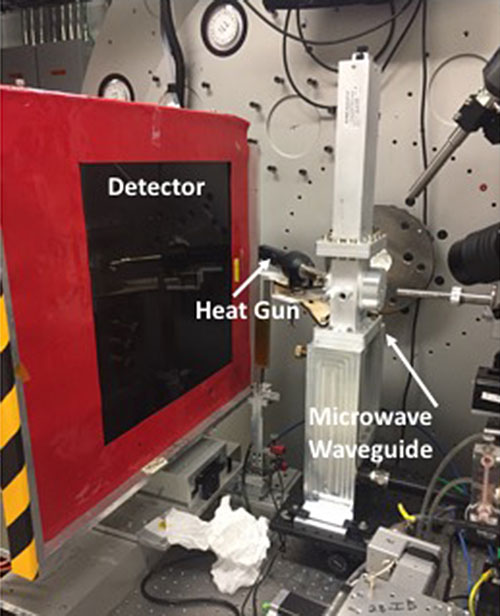

In-situ PDF Data Collection: Waveguide installed at 28-ID-2 beamline at the National Synchrotron Light Source II, Brookhaven National Laboratory. The results in Jayan's paper came from the custom-built microwave reactor, which offers precise engineering controls. (Source: Reeja Jayan)

“Once we know the dynamics, we can use this knowledge to make materials that are far away from equilibrium, as well as devise new energy efficient processes for existing materials, such as 3D printing of ceramics,” she says. The commercialization of additive manufacturing of metals and plastics is widespread, but the same cannot be said for ceramic materials. 3D printing of ceramics could advance industries ranging from healthcare—imagine artificial bones and dental implants—to industrial tooling and electronics—ceramics can survive high temperatures that metals can’t. However, integrating ceramic materials with today’s 3D printing technologies is difficult because ceramics are brittle, ultrahigh temperatures are required, and we don’t understand how to control their properties during printing processes.

Jayan’s findings were derived from unconventional experiments that relied on a combination of tools. She used x-ray pair distribution function (PDF) analysis to provide real-time, in situ structural information about tin oxide as it was being exposed to microwave radiation. She compared these results to tin oxide that was synthesized without electromagnetic field exposure. The comparisons revealed that the microwaves were influencing atomic-scale structure by disturbing the oxygen sublattice. “We were the first to prove that microwaves create such localized interactions by devising a method to watch them live during a chemical reaction,” says Jayan.

enlarge

enlarge

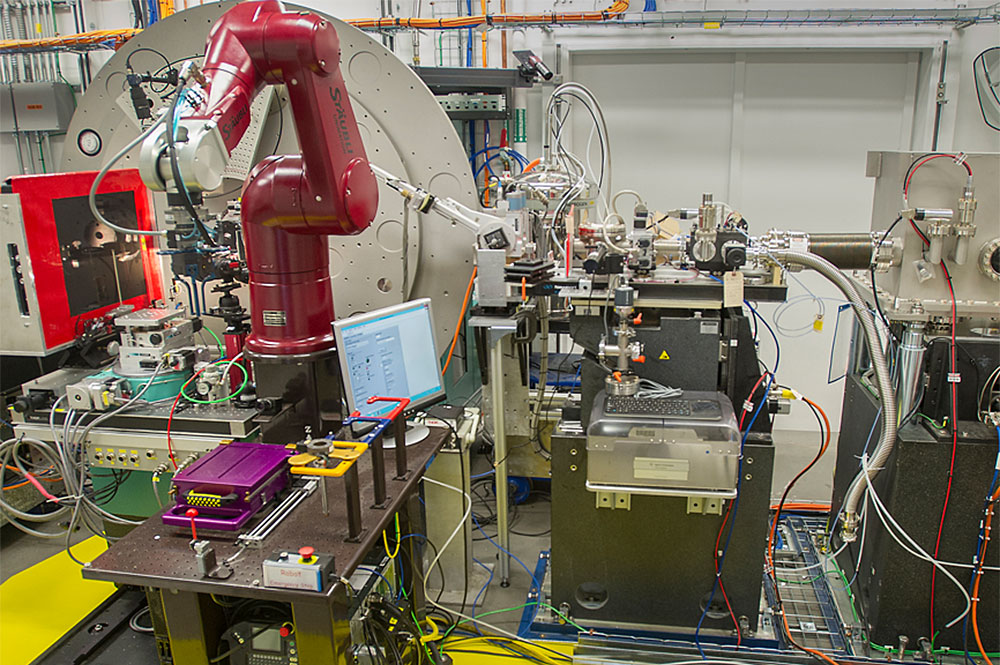

The custom-built microwave reactor was integrated into the X-ray Powder Diffraction (XPD) beamline located at the US Department of Energy Brookhaven National Laboratory.

These experiments were extremely difficult to conduct and required a custom-built microwave reactor. (This represented a significant upgrade in cost and engineering compared to the original domestic oven). The reactor was designed in collaboration with Gerling Applied Engineering, and the experiments were conducted at the US Department of Energy Brookhaven National Laboratory (BNL). Dr. Sanjit Ghose and Dr. Jianming Bai, lead scientists at BNL, were instrumental in helping Jayan’s team integrate the microwave reactor into the beamline.

“Another takeaway from this research is that microwaves can do more than just heating. They can have a non-thermal effect, which can rearrange the structure of materials like a jigsaw puzzle,” says Jayan. Building on this concept, she is investigating how to use microwaves to engineer new materials.

The results of Jayan’s research were published in the Journal of Materials Chemistry A. The paper was recognized as part of the 2020 Emerging Investigators Issue of the journal. Jayan’s work was supported by a Young Investigator grant from the U.S. Department of Defense, Air Force Office of Scientific Research.

2020-17398 | INT/EXT | Newsroom