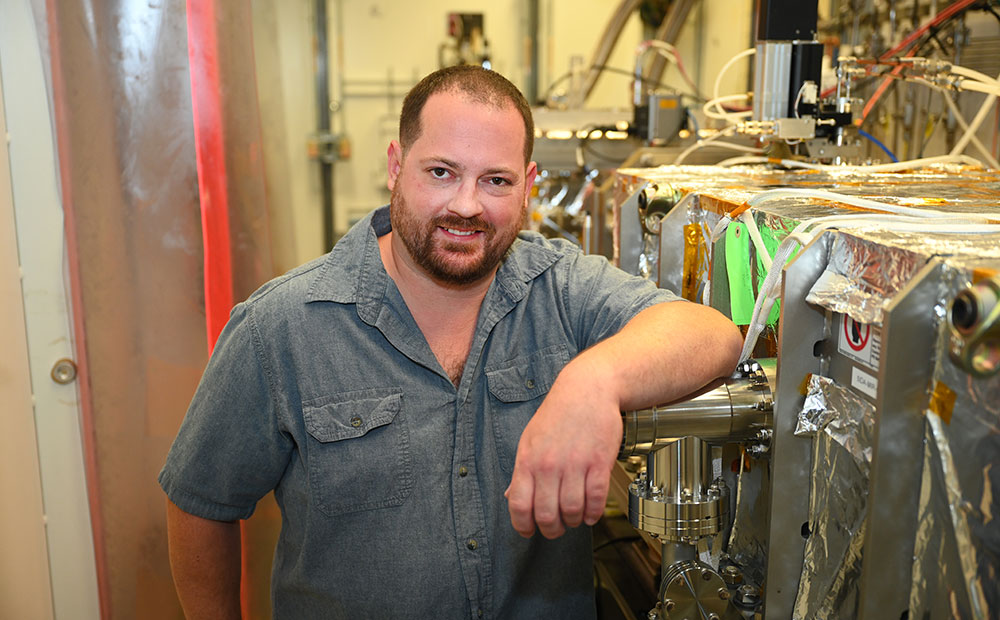

Meet Michael Maklary, NSLS-II Electro-Mechanical Technician

Maklary provides beamline and scientific workspace support for NSLS-II's imaging and microscopy program

December 4, 2023

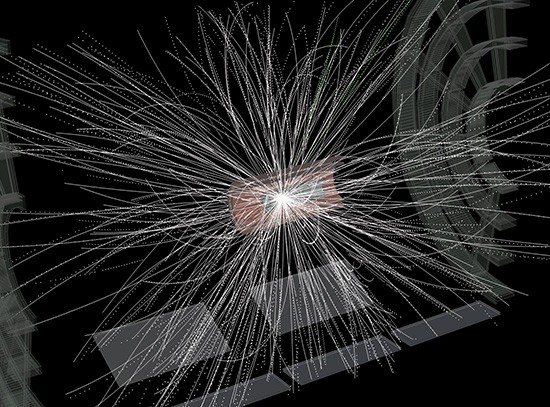

Mike Maklary is an electro-mechanical technician for the imaging and microscopy program at National Synchrotron Light Source II (NSLS-II), a U.S. Department of Energy (DOE) Office of Science User Facility located at DOE’s Brookhaven National Laboratory. The NSLS-II facility produces ultrabright beams of synchrotron light, from infrared to x-rays, that scientists use to study a wide range of materials and biological samples.

What is your role at NSLS-II?

I am responsible for many support functions for the five beamlines that make up the imaging and microscopy program. For example, I am involved in construction and upgrades of the experimental areas. One of the main ways I do this is by designing and fabricating parts—I am a computer numeric controlled (CNC) machinist, which means that I use large computer-controlled machines to input the designs and produce what we need.

The NSLS-II technicians and engineers are often considered jacks-of-all-trades. Do you find that to be true in your case?

I agree with that—I do a little bit of everything. I’m also the machine shop supervisor, which requires me to maintain different pieces of machinery, qualify people to use the equipment, and make sure they are using it safely.

I also do a lot of mechanical assembly of systems, including vacuum work. I work with the rigging crew to move in the equipment and then work with the engineers, designers, and scientific staff to do the installation. Additionally, I am a work control coordinator. I work hand-in-hand with various groups to make sure all jobs are being done safely.

I also have an administrative role, being the credit card holder for my group. This means that I’m in charge of a lot of the purchasing that is required.

What is a typical workday like for you?

My workday begins at home, where the first thing I do is check my phone for any emergencies that may have arisen overnight or in the early morning. If all is well, I usually log into my computer when I arrive at work, check email, and determine what needs to be done that day. Depending on the day, I might attend a “morning toolbox” meeting hosted by NSLS-II Accelerator Division Deputy Director for Projects Greg Fries and Photon Sciences Directorate Liaison Engineer Steve Sherwood. The meeting brings together many of the work control coordinators and supervisors. I also have a weekly meeting with my group where we discuss upcoming tasks.

Even when the facility is operating smoothly, I don't have a typically structured day. I get requests to make parts, design parts, or do installations. I do a lot of one-off type of projects. Some of these parts need to be made on the CNC mill, which means I have to take the time to tell the machine what to do and how to do it. This part of my job is not particularly exciting but it’s necessary.>

What are some recent projects that you have worked on?

An exciting project I am involved with is a new end station installation at the Tender Energy X-ray Absorption Spectroscopy (TES) beamline. This particular installation has been very hands-on, as it was designed here at NSLS-II and many of its parts were fabricated at Brookhaven Lab—and not to mention, we physically assembled just about every bit of hardware.

I’m also working on a sample holder right now that will be used on various beamlines in my program. Additionally, I recently worked with a vendor to put in a new mirror system at the Hard X-ray Nanoprobe (HXN) beamline.

Let’s talk about your background. What brought you to Brookhaven?

I started in 2011 as a job shopper during the construction phase of NSLS-II. I was a cable puller, which is exactly what it sounds like it is. Just about everything at the Lab has wires and cables attached to it, and my task was to move those wires wherever they needed to go. I did that for the construction of the accelerator and, once that part was over, I moved on to the construction of the beamlines.

I was fortunate in that I was given the opportunity to continue on at the Lab and become more involved. That’s when my job really started taking off. I have to acknowledge the late NSLS-II beamline technician James Biancarosa for his critical role in that. He took me under his wing and was a mentor to me. He is a big, big part of my growth at Brookhaven.

Did you plan on a career in the science and technology field?

Actually, no—I never expected to work at Brookhaven, but I did always enjoy science and technology. In high school, I took every single elective related to that. I have always been mechanically inclined, but after high school I attended Long Island University and got my bachelor’s degree in criminal justice, which is very different than what I’m doing now. After graduation, I was working part time for different law enforcement agencies on Long Island. I also worked at a custom glass company, where we installed custom windows, doors, and enclosures for residential properties.

Then, my brother, who was a surveyor at NSLS-II, told me that the Lab needed people to pull cables. I saw it as an opportunity to make some additional income and try something new. It turned out to be really great, working with my mentor and being involved in every single thing that we did in a hands-on way. It was a very valuable on-the-job learning experience for me and I’m hoping to mentor someone myself one day.

What do you enjoy about your job? What are the challenges?

I like that no day is the same. There is always a fire to put out so that the science can happen. During operations, I’m almost like an emergency response technician. Though I’m not a police officer, like I had planned to be at one point, I’m still responding to emergencies.

But you’ve got to make it happen for the users. The scientific and engineering staff all work together to make sure that the users can take advantage of the beam—and hopefully help to solve the world’s problems.

An example of this happened just recently, causing me to reschedule my appointment with the photographer for this piece. After our facility-wide power shutdown in August, one of my three liquid nitrogen cryocoolers did not recover properly. The cryocoolers are essential for operation at three of my program’s beamlines because they send liquid nitrogen to the crystals of the monochromator—one of the beamline optics—to cool them down. This is necessary because the energies of those beamlines cause the optics to heat up quite intensely. Other beamlines experience the same thing, but to a lesser degree, such that water cooling is sufficient.

With operations lurking around the corner, I had to do all I could to make sure the cryocoolers were operating correctly. This effort carried on so long that another member of my team and I were remotely logging into workstations at the beamline at off hours to check for any major status changes. Sure enough, two days before operations resumed—and, of course, on the weekend— we responded to NSLS-II, completed the final preparation tasks, and cooled down our monochromator crystals successfully with less than 48 hours to spare. It feels like the middle of the night and weekends are when most emergencies or time sensitive tasks like to occur. Needless to say, I slept a bit better that night.

Tell us a bit about life outside of work.

I am happily married to my wife, Jen, and we have two beautiful little girls. My eldest is six and my youngest is three. I enjoy being a dad and a husband; I like to do things with the girls and we all like to go on vacation when we can.

I enjoy fishing and have been trying to get my girls involved in that. My wife and I also love to cook.

Brookhaven National Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit science.energy.gov.

Follow @BrookhavenLab on social media. Find us on Instagram, LinkedIn, Twitter, and Facebook.

2023-21571 | INT/EXT | Newsroom