New Supercomputers at Brookhaven will Advance Nanomaterial Design

March 22, 2012

Just one rack of the Blue Gene/Q supercomputer, seen here with its complex wiring and cooling tubes exposed, will rapidly perform complex tasks that would require 18 racks of the previous generation of IBM supercomputers.

Heavy construction projects demand precision and planning, particularly if the end products need to perform a specific function. The degree of complexity increases as the raw materials become smaller and more specific: Just consider the difference between constructing a house, a car, or the tiny circuitry within a computer. The challenges and opportunities of ground-up design are rarely more pronounced than on the nanoscale — the scale of billionths of a meter — where atoms and molecules are the basic building blocks.

Atomic-level tailoring promises important breakthroughs in energy technology, such as the development of new materials that will make efficient fuel cells inexpensive enough for widespread use. But nanoscale engineering requires cutting-edge facilities and expertise in the dizzying laws of quantum mechanics that govern the interactions between atoms. The sheer number of variables in effect during any chemical reaction would make complete understanding impossible without another essential tool: a powerful computer to connect the atomic dots.

This spring a new supercomputer will come online at the Department of Energy’s Brookhaven National Laboratory, arming its scientists and engineers with a cutting-edge tool to advance their research. Brookhaven’s Center for Functional Nanomaterials (CFN) and the Chemistry Department will use this big boost in computing power, called Blue Gene/Q, to tease out new ways to put nanoscale materials to work. In particular, Blue Gene/Q will decode and map out the complex array of chemical reactions that can occur on a single nanoparticle with greater speed and precision than ever before.

“Computer modeling is the key to the rational design of catalysts,” said Mark Hybertsen, who leads the Theory and Computation Group at CFN. "This machine will more rapidly advance the development of new electrocatalysts for use in clean-burning fuel cells.”

The new Blue Gene/Q, the latest version in the IBM supercomputer series that includes Brookhaven Lab’s Blue Gene/L, will add 600 teraflops, or floating operations per second, of processing power. Only three racks of the new Blue Gene/Q will soon complete operations that required 18 racks of the previous generation machine. The system consists of two racks for the RIKEN BNL Research Center (RBRC) operated with Japan, and a third belonging exclusively to Brookhaven and run by the Computational Science Center (CSC). It all boils down to handling more complex data at faster speeds and giving scientists throughout Brookhaven access to that computational power.

Like many scientific disciplines, building and understanding nanomaterials requires teamwork and strong integration of experiment and theory. Experimental work provides tremendous data, but often the theoretical computer analyses point the way toward future innovations.

“Over the past decade, growing computational power has transformed the practice of catalysis science,” said Alex Harris, Chair of Brookhaven’s Chemistry Department. “Calculations of atomic and electronic structure can now give reliable insight to guide the design of better catalysts. We’re excited to see what Blue Gene/Q can do, and we appreciate the effort of the CSC to get the key software tools for catalyst modeling up and running.”

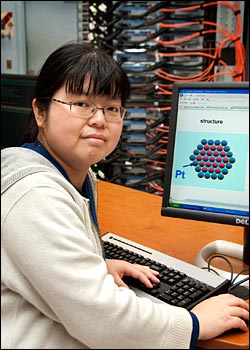

Brookhaven chemist Ping Liu, who helps guide the integration of computational theory and experimentation, sits in front of an open Blue Gene/Q supercomputer rack, showing a schematic of a platinum-shell electrocatalyst designed at the CFN.

As scientists seek to discover the most efficient catalysts for specific applications, they audition many new compounds. Platinum, for example, is an excellent catalyst for many applications, but it is both rare and expensive. One innovation pioneered at Brookhaven reduced the platinum to a one-atom thick layer coating over a less-expensive metal such as palladium. On the atomic scale, the individual platinum atoms then “felt” the influence of the palladium atoms below, instead of platinum atoms. Difficult questions arose about whether or not the chemical reactions on the surface would still produce the same reactions, and if the palladium nanoparticles with their fancy platinum coats would remain stable or shed their new skin.

Experiments showed that not only was this novel core-shell structure stable, but it was an even better catalyst than pure platinum particles in fuel cells. In a surprising discovery, nanoparticles with a partially hollow palladium core actually functioned even more efficiently. That’s when the power of computer simulations came into the picture to explain those results, led by Ping Liu of the Chemistry Department and the CFN.

“The computer calculations revealed to us why the hollow core-shell nanoparticle was the most stable and the best catalyst at the same time. The thin palladium layer in the core led to strain and electronic effects throughout that not only stabilized the catalyst, but promoted the catalytic activity of platinum.” Liu said. “In fact, we learned that the stability of these particles depends on their size, and in the future we will need to study and model even more complex particles with hundreds or thousands of atoms.”

With the detailed information about the atomic-scale interactions available from the computer simulations, the scientists can examine how the catalyst might be improved by small changes, such as substituting gold atoms for palladium atoms in these core-shell particles. The new Blue Gene/Q will make these challenging calculations feasible, allowing theory to guide future experimentation.

Upgrades like Blue Gene/Q will help take nanoconstruction along a similar path, Hybertsen said. With greater processing speed, breakthroughs in energy technology may become both more frequent and more innovative.

2012-2869 | INT/EXT | Newsroom