Sulfur Polymer Material Poised for Commercialization

May 19, 2015

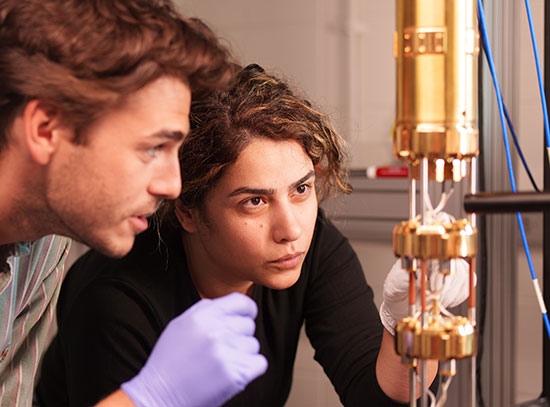

Preparing to load materials for pilot-scale SulfCrete equipment testing.

Long Island start-up company SulfCrete, Inc. has been exploring commercialization of sulfur polymer, a unique and affordable construction material developed at Brookhaven Lab that has a very small carbon footprint compared to the existing concrete products it might one day replace.

Production of concrete, a ubiquitous construction material, is one of the biggest contributors to our world’s carbon footprint. Between the energy needed to heat limestone – one of concrete’s key ingredients – and the carbon dioxide released when producing cement, concrete production is estimated to be responsible for five to ten percent of all greenhouse gases released to the atmosphere.

SulfCrete, Inc. has licensed the technology from Brookhaven Lab, and its product, which uses sulfur polymer to replace cement, will be more than 90 percent “greener” than existing concrete. Unlike conventional cement, which requires the addition of water and a chemical hydration reaction to set and cure over time, sulfur polymer is melted, mixed with aggregate, and cures to 90 percent full strength within hours after cooling to ambient temperatures.

To learn more about this exciting technology visit: www.bnl.gov/newsroom/news.php?a=25063

2015-5722 | INT/EXT | Newsroom