Toyota to Use Brookhaven Lab's Center for Functional Nanomaterials to Advance Vehicle Battery Tech

Scientists will collaborate with Brookhaven experts and use world-leading electron microscopes to explore the real-time electrochemical reactions in promising new batteries

October 30, 2014

enlarge

enlarge

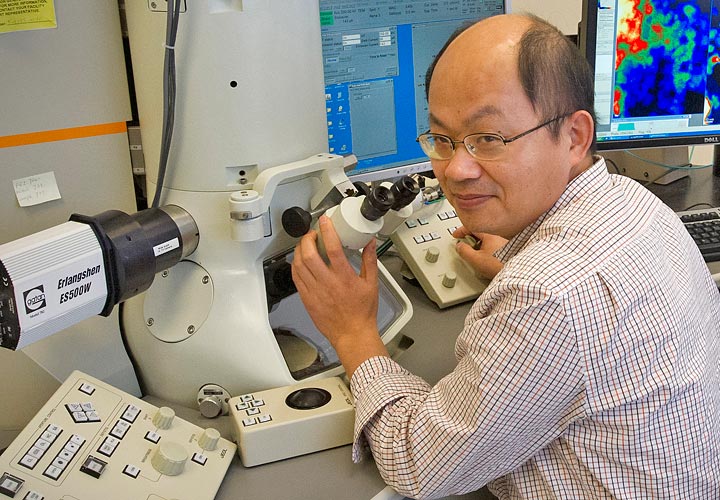

Brookhaven Lab scientist Feng Wang of Brookhaven Lab's Sustainable Energy Technologies Department, who will lead the collaboration with Zhang's team at CFN.

Future fleets of electric vehicles will require high-capacity batteries that recharge rapidly, degrade very little over time, and operate safely. Lithium-ion (Li-ion) batteries—similar to the ones found inside portable electronics—currently lead the charge, but not without significant problems.

“Issues related to cost, power, energy density, and durability of Li-ion batteries have slowed their implementation in large-scale applications, such as electric and hybrid vehicles,” said Ruigang Zhang, a Toyota Motor Corporation scientist specializing in energy storage technology. “A rechargeable magnesium (Mg) battery system is one interesting candidate that offers much greater earth abundance than lithium and higher storage capacity—but the necessary research remains a challenge.”

“Toyota’s research goals are a perfect match for our expertise in tracking the real-time chemical reactions of cutting-edge materials.”

— J. Patrick Looney, Chair of Brookhaven Lab’s Sustainable Energy Technologies Department

To probe molecular structures and track the rapid chemical reactions in these promising batteries, Zhang and colleagues turned to the Center for Functional Nanomaterials (CFN) at the U.S. Department of Energy’s Brookhaven National Laboratory.

“CFN possesses a full suite of powerful observational and analytical instruments,” said scientist Feng Wang of Brookhaven Lab’s Sustainable Energy Technologies Department, who will lead the collaboration with Zhang’s team at CFN. “With our newly developed imaging techniques, we are able to track the magnesium reactions in real time with nanoscale resolution, letting us understand how and why structural disorder emerges and impacts performance. And it is personally exciting to analyze and optimize materials that may one day make transportation more sustainable.”

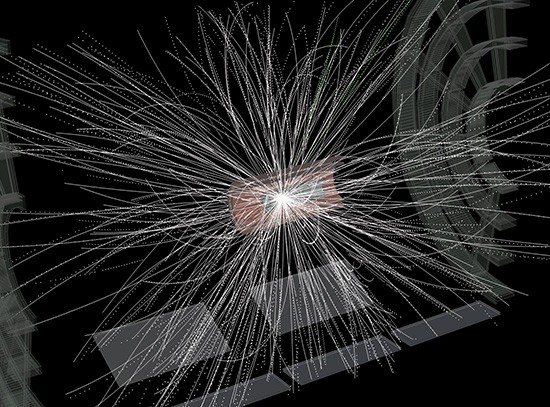

In rechargeable batteries, ions are shuttled back and forth between the oppositely charged anode and cathode—flow in one direction generates electricity (discharge), while applying external voltage causes flow in the other (charge). Magnesium ions carry twice the intrinsic charge of lithium ions, meaning they store and deliver more energy. But as those ions move during each cycle, the billionth-of-a-meter structure of the battery material degrades and transforms.

The degradation rates and patterns—whether uniform or asymmetrical—must be probed in a variety of conditions to understand the underlying mechanisms. Once pinpointed, scientists can then design new atomic architectures or customized compounds that overcome these obstacles to extend battery lifetimes and optimize performance.

The Toyota researchers plan to target the specific chemistry of a promising magnesium cathode composed of hollow carbon molecules called fullerenes. The compound offers consistent energy output, a rapid cycling rate, and extremely low voltage hysteresis—meaning it stays relatively intact even after many cycles of charge and discharge. Despite all that, the performance and ease of battery integration still need work, and scientists need a full understanding of structural evolution, crystallization mechanisms, and other factors influencing the electrochemical reactions.

“Unfortunately, our preliminary x-ray diffraction (XRD) results indicated material amorphization—a loss of crystalline structure—during operation that makes it challenging to follow the structural evolution,” Zhang said. “We now plan to use the advanced electron microscope facilities at CFN for local structural studies, particularly to track the reaction as it occurs rather than just before or after.”

enlarge

enlarge

Brookhaven Lab's Center for Functional Nanomaterials, home to world-leading electron microscopy instruments and expertise.

Zhang’s team will work with Wang to use CFN’s high-resolution transmission electron microscopy (TEM) and electron energy loss spectroscopy (EELS) techniques to identify morphologies and chemical elements as they emerge or transform. In these techniques, a focused beam of electrons strikes and interacts with the material’s atomic structure and then carries that information into highly sensitive detectors.

“Toyota’s research goals are a perfect match for our expertise in tracking the real-time chemical reactions of cutting-edge materials,” said J. Patrick Looney, who leads Brookhaven’s Sustainable Energy Technologies Department. “Our focus on connecting fundamental with use-inspired science aligns well with the very practical challenges tackled by Toyota and other industrial collaborators.”

Wang will work alongside CFN’s electron microscopy staff and other experts across Brookhaven Lab to facilitate Toyota’s research and even pioneer new technologies and techniques.

“Down the road, we also plan to use Brookhaven’s powerful new x-ray light source facility, the National Synchrotron Light Source II, to investigate battery properties and reaction evolutions in real time under real-world reaction conditions,” Zhang said.

The world-leading NSLS-II, scheduled to begin operations in 2015, will achieve single-nanometer resolution and enable unprecedented in operando energy research.

“CFN and NSLS-II share a singular partnership, allowing scientists from all over the world to synthesize, characterize, and analyze materials at one location,” said CFN Director Emilio Mendez. “This kind of collaboration aligns with our own mission of addressing the nation’s energy challenges as well as providing an unparalleled service to external users, including those from industry. We will operate several beamlines at NSLS-II, and I’m eager to see the kinds of breakthroughs achieved by Toyota and other users.”

Added Zhang, “Solving the magnesium challenges may open the door for other multivalent batteries such as cadmium or aluminum, thereby shedding light on the next generation of battery technology.”

Brookhaven National Laboratory is supported by the Office of Science of the U.S. Department of Energy (DOE). CFN and NSLS-II are both DOE Office of Science User Facilities. Toyota researchers gained access to the facilities on a competitive peer-reviewed basis as users undertaking open, non-proprietary research.

The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.

2014-5125 | INT/EXT | Newsroom