Brookhaven to Receive Department of Energy Funding for Battery Manufacturing

April 1, 2021

A collaboration led by the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory, partnering with DOE’s Argonne National Laboratory and New York-based manufacturers C4V and Primet, has been awarded $1.7 million dollars in federal funding to conduct a $4.05 million project to scale up the processing technologies for the manufacturing of manganese-nickel-cobalt (MNC)-based cathodes for lithium-ion batteries (LIBs). The partnership was formally developed through the use of a multi-party Cooperative Research and Development Agreement (CRADA) coordinated by BNL’s Strategic Partnership Programs office.

This effort is an extension of the established partnership between national laboratories and leading manufacturing companies in NY State. It is one of 13 projects that have been selected to receive a total of $15 million in funds for battery manufacturing research from the Advanced Manufacturing Office (AMO) and Vehicle Technologies Office (VTO) within DOE’s Office of Energy Efficiency & Renewable Energy (EERE), with matching funds from the private sector and investors. The funding was designed to establish public-private partnerships that address engineering challenges for advanced battery materials and devices, with a focus on developing new technologies.

This collaboration will, in part, help to create a commercially viable process to produce a new generation of LIBs that are powerful, low-cost, and easy to manufacture but require less cobalt, a metal that is in low supply and is difficult and environmentally harsh to mine.

The partnership was initiated, established, and organized by the Industry Liaison Office within Brookhaven’s Energy & Photon Sciences (EPS) directorate. Establishing a collaboration with industry is a required component of this proposal and was vital for the success of this award.

“I’m happy our industrial research program played a key role in helping the proposal to be funded,” said Jun Wang, the Industrial Liaison Officer for EPS, “We will continue to develop industrial partnerships of this kind.”

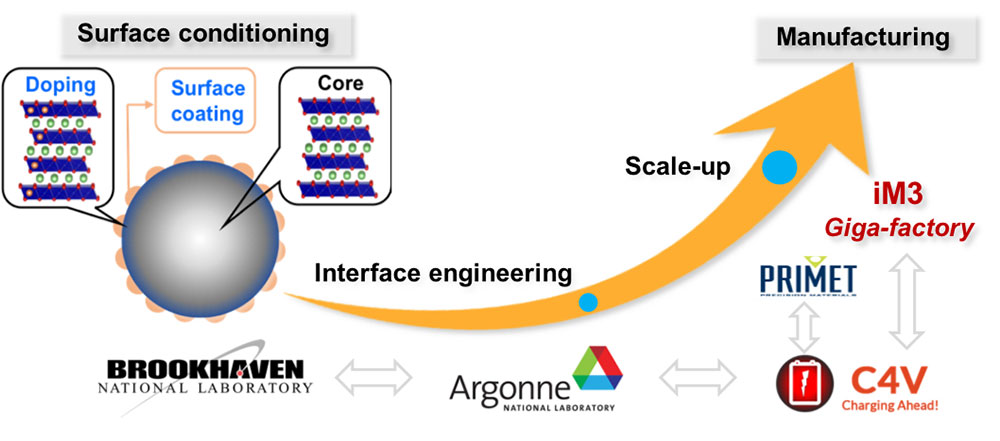

This project is the first at Brookhaven to receive AMO funds. It proposes a scalable “surface conditioning” process for the high-nickel, low-cobalt NMC cathodes (positive electrodes) of LIBs. This conditioning is a necessary step that addresses the instability of the cathode surface; this approach integrates the surface coating/doping process (the additional of very small amounts of an element or compound to boost performance) into the synthesis of the cathode materials.

“This new Brookhaven-led program is an exciting opportunity and part of the EPS strategy in energy storage. I am delighted that this program was awarded and look forward to further growth in this area with the heightened awareness of the importance of energy storage,” says Esther Takeuchi, chair of the Interdisciplinary Science Department (ISB) at Brookhaven Lab.

This project will leverage the innovations and capabilities in materials synthesis/processing and interface engineering established at Brookhaven and Argonne, which were funded through various projects by EERE/VTO. Diagnostic studies ranging from the materials level to large-format cells will utilize the x-ray and electron microscopy facilities at the National Synchrotron Light Source II and the Center for Functional Nanomaterials, both DOE Office of Science User Facilities at Brookhaven.

“The technologies were developed under various projects funded through DOE, from the VTO, and have only been exercised at the laboratory scale so far. We hope to extend the use of those technologies for industrial production, through scaling up and cell prototyping, by partnering with industry,” said the project’s principal investigator, Feng Wang, a materials scientist in ISB. “The technology will enable mass production of high-Ni, low-Co cathodes, with low cost and high performance, for large-scale use, such as batteries for powering electric vehicles.”

The global LIB market has grown steadily over the last 10 years, from less than 10 GWh per annum to more than 100 GWh per annum. Future global LIB production is forecasted to exceed 300 GWh over the next five years and reach more than 1,500 GWh by 2030; it is effectively a $300 billion-dollar industry. Such rapid market growth is a result of product substitution, rapidly falling production costs, and the rise of new applications for these batteries. This has led China, Korea, and Japan to scale up production massively, and now Europe and North America have joined in, with several gigafactories under construction.

The process will initially be appropriate for smaller, pre-commercial production volumes, but will later be taken to market by C4V and produced in ton quantities by Primet, to eventually be adopted by C4V’s “iMperium3” gigafactory, which will be the first of its kind in NY State. It is scheduled to produce LIBs at a mass scale by the middle of 2021. These two companies have been critical to the commercialization of innovative technologies for making more efficient and less expensive batteries.

“Advancing manufacturing science for electrochemical energy storage is key to the future of U.S. economics and technical competitiveness in the field of vehicle technology and beyond. We are pleased to advance this strategically important field and appreciate the support from EERE, AMO, and VTO,” said Amy Marschilok, manager of ISB’s Energy Storage Division.

The focus of the collaboration between Brookhaven, Argonne, C4V, and Primet has been to bridge the gap between laboratory research and large-scale battery manufacturing. To fast-track the commercialization of the technology, C4V would establish a well-qualified supply chain for every step of the development.

This process could improve the sustainability of the LIB market by reducing its dependence on cobalt, which, in turn, could have effects on other industries, such as boosting the electric vehicle market.

“While the U.S. has always been at the forefront of innovation of LIBs, with two Nobel Laureate-winning awards for their pioneering work in the field, it is behind on commercialization and manufacturing. This project directly aligns the national interest with a goal to invent here and manufacture here,” said the CEO of C4V, Shailesh Upreti, who leads efforts in building iMperium3.

This funding opportunity is part of the Energy Storage Grand Challenge, a DOE-wide effort to create and sustain global leadership in energy storage utilization and exports, with a secure domestic manufacturing supply chain that does not depend on foreign sources of critical materials. Visit the Energy Storage Grand Challenge website to learn more.

Brookhaven National Laboratory is supported by the U.S. Department of Energy’s Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit https://energy.gov/science.

Follow @BrookhavenLab on Twitter or find us on Facebook.

2021-18801 | INT/EXT | Newsroom