Elevating X-Ray Optics to the Next Level

Scientists developed a new method to for high-precision mirror fabrication

June 30, 2021

enlarge

enlarge

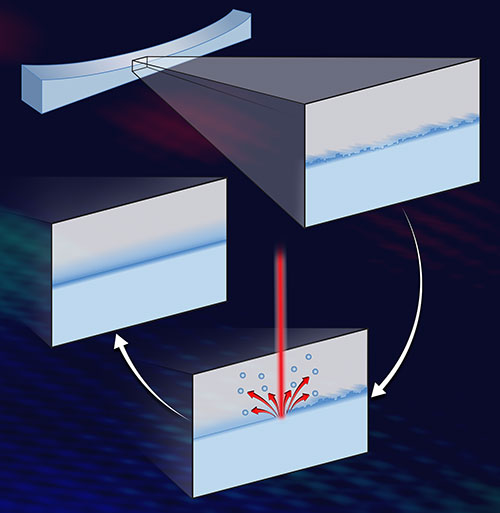

The illustration shows how a used x-ray mirror can be repolished using an ion beam. After this treatment, the newly polished mirror has an enhanced performance up to the diffraction limit. Image credit: Brookhaven National Laboratory

The Science

Scientists demonstrated a method to perform sub-nanometer level x-ray mirror fabrication by coupling state-of-the-art optical metrology and ion-beam figuring (IBF) to polish x-ray mirrors for performance at the diffraction limit.

The Impact

Advances in materials science strongly depend on the brightness of synchrotron light sources, and more light sources can create extraordinarily bright light beams. However, there is a very limited supply of mirrors that can deliver these beams to each experiment. This study opens a new pathway to polishing x-ray optics to reach this ultimate performance.

Summary

From batteries and microelectronics to drug design and future quantum computers, scientists are constantly advancing our understanding of materials to solve the world’s greatest challenges. However, today's problems are so complex that they require researchers to study materials with highly specialized tools that are not readily available at most institutions. This is where synchrotron light sources, such as the National Synchrotron Light Source II (NSLS-II), come in. These facilities create highly intense x-rays to investigate the inner structure and dynamics of materials. While the particle accelerators that create these extraordinary beams start to reach light’s near ultimate quality, the currently existing x-ray optics necessary to focus this x-ray beam to the experiments must continue to improve.

In this study, a team of researchers proposed a pathway to polish x-ray mirrors so that they can deliver these ultrabright beams to the experiments. The team demonstrated that they can re-polish existing mirrors to perform at the diffraction limit by using the ion-beam figuring (IBF) process. The diffraction limit describes the minimum focusing spot size (or the optimal resolution) an optical system can achieve. So far, reaching the Diffraction limit has been limited by imperfections or misalignment of the optical system.

To reach ultimate mirror performance, the team developed a new method that couples state-of-the-art optical metrology with an optimized polishing process called Robust Iterative Surface Extension (RISE) method. This method addresses several problems with existing models, such as high sensitivity to boundary errors and noise.

The team built a dedicated ion-beam figuring (IBF) setup for mirror polishing and state-of-the-art mirror metrology. Using their laboratory setup, coupled with state-of-the-art mirror metrology, the scientists could then demonstrate that they can polish a mirror with the sub nanometer precision as predicted by the RISE model.

This method of mirror polishing will enable new synchrotron light sources to deliver more intense x-rays to their experimental stations and, therefore, enhance the scientific output.

Download the research summary slide

Contact

Tianyi Wang

National Synchrotron Light Source II

tianyi@bnl.gov

Lei Huang

National Synchrotron Light Source II

lhuang@bnl.gov

Heejoo Choi

James C. Wyant College of Optical Sciences

9hchoi@optics.arizona.edu

Publications

T. Wang, L. Huang, H. Choi, M. Vescovi, D. Kuhne, Y. Zhu, W. C. Pullen, X. Ke, D. W. Kim, Q. Kemao, K. Tayabaly, N. Bouet, M. Idir, "RISE: robust iterative surface extension for sub-nanometer X-ray mirror fabrication," Optics Express 29, 15114-15132 (2021) https://doi.org/10.1364/OE.419490

Funding

Resources of the National Synchrotron Light Source II, a US Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Brookhaven National Laboratory under contract no. DE-SC0012704); Brookhaven National Laboratory (BNL LDRD 17-016).

2021-19015 | INT/EXT | Newsroom