Designing a Better Catalyst for Solar-Powered Hydrogen Production

December 3, 2013

enlarge

enlarge

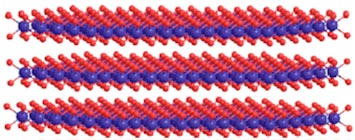

Ball-and-stick representation of nanoscale clusters within cobalt-based thin film using borate electrolyte (red spheres are oxygen, blue spheres are cobalt)

Hydrogen is a “green” fuel that burns cleanly and can generate electricity via fuel cells. One way to sustainably produce hydrogen is by splitting water molecules using the renewable power of sunlight, but scientists are still learning how to control and optimize this reaction with catalysts. At the National Synchrotron Light Source, a research group has determined key structural information about a potential catalyst, taking a step toward designing an ideal material for the job.

Due to the mechanical and electrical complexity of the water-splitting reaction, there are many requirements in order for a catalyst to perform optimally. Scientists must understand not only a candidate’s local molecular structure but also its structure over longer ranges – particularly the nanoscale, which tends to be a good indicator of a material’s electronic behavior and therefore its overall catalytic activity.

Scientists are increasingly focusing on a particular group of catalysts: cobalt-based thin films. These films are created via electrodeposition from aqueous solutions of cobalt mixed with an electrolyte. In this study, researchers from Columbia University, Harvard University, and Brookhaven Lab used x-rays to better understand the intermediate-range nanoscale structure of one of these films. They also investigated the structural differences between films grown using two electrolytes: phosphate, a negative phosphorous-oxygen ion, and borate, negative a boron-oxygen ion. The resulting films are denoted CoPi and CoBi, respectively.

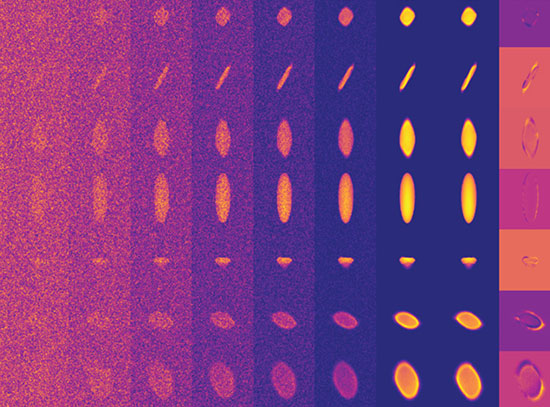

X-ray scattering data from the CoPi and CoBi samples, taken at NSLS beamline X7B, indicate that both are nanocrystalline. This means that they consist of nanoscale grains, each ranging from about 1.5 to 3 nanometers (nm) in size with an ordered molecular structure. Aside from this, there are clear and important differences.

The CoBi films consist of 3-4 nm cobalate (cobalt–oxygen) clusters that stack neatly up to three layers deep. The CoPi films consist of significantly smaller clusters that do not stack in an ordered way.

These structural differences seem to tie into the films' catalytic activity. Electrochemical data show that, as film thickness increased, the CoBi films were more active than CoPi and ultimately displayed a “significantly superior” performance. These findings suggest that the increase in CoBi film thickness also increases the effective surface area available for catalysis, while at the same time preserving the charge-transport properties of the films.

“Our results show a concrete difference between CoBi and CoPi, thus allowing the first insight into a tangible structure-function correlation,” said Harvard chemist and professor Daniel Nocera.

The group plans additional studies to explore some related issues, such as the nature of charge transport between the CoBi layers and the films' behavior over ranges longer than the nanoscale.

This research is published in the April 2, 2013, online edition of the Journal of the American Chemical Society. It was supported by the U.S. Department of Energy.

2013-4444 | INT/EXT | Newsroom