Brookhaven Sets the Standard for Chemical Management with RFID and "BNL Flag Tag"

September 24, 2020

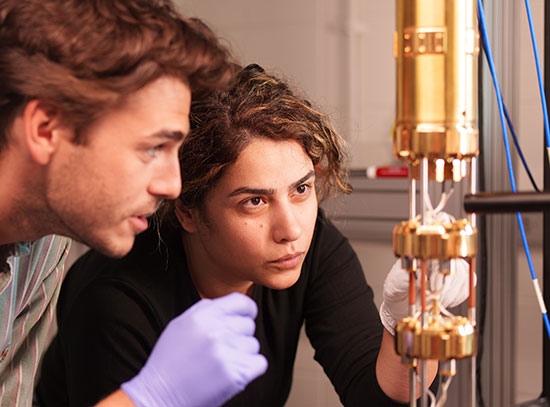

Thanks to the ingenuity and teamwork of a group of Brookhaven Lab employees, the way chemicals are tracked, used, and disposed of at Brookhaven is now safer and more efficient—and considered a best practice.

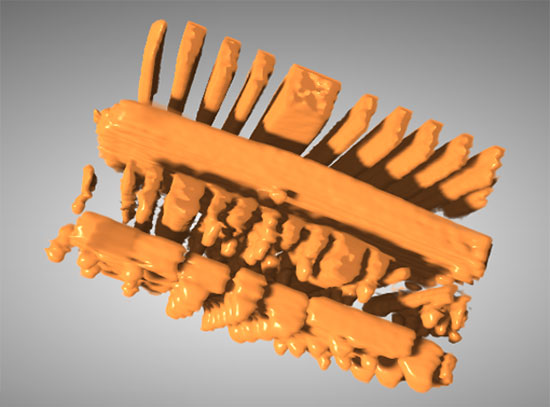

Every chemical container at Brookhaven has a radio frequency identification (RFID) tag – also known as a “flag.” RFID is an advanced method of data collection that uses electromagnetic fields to immediately identify objects via an RFID reader, or scanner. The tagging system, which was painstakingly applied to about 45,000 containers across the Lab site by a handful of Safety & Health Services Division (SHSD) staff, allows users to locate chemicals in a fraction of the time it used to take when optical bar codes were the standard for marking chemicals.

But it isn’t just the savvy application of a technology, the cross-Lab coordination, and immense scope of application that are worth noting.

As a result of this massive effort, Brookhaven was the first U.S. Department of Energy site to conduct a full chemical inventory and place an RFID tag on every one of its chemical containers. Getting to this point of 100 percent tagging was no small feat.

Chemical Management: Paper Labels to Optical Scanners to RFID

Brookhaven’s chemical management system (CMS) was established in the late 1980s when the U.S. Occupational Safety & Health Administration established a hazard communication standard. It relied on paper labels with bar codes, which could be read by optical scanners. This was a major advance for safety—and for inventory management.

“This was valuable, because we could track each chemical in the Laboratory, but to go in and to do an inventory, checking every bottle by hand, was very time-consuming,” explained CMS Team Manager Joe Pavlak.

Taking inventory of a cabinet full of chemical containers was a painstaking process. It meant physically retrieving, turning, scanning, and noting each bottle individually. A cabinet with 20 containers could take five minutes or more. Multiply that by the more than 45 thousand containers across the entire Lab site, and the opportunity for errors was enormous. The CMS database was often out of date and incomplete.

But knowing which chemicals were available, in short supply, or going old and inert helped Lab scientists and the Lab’s Procurement & Property Management Division know what needed to be purchased to keep experiments going.

Around 2010, a few SHSD staff learned of an opportunity to improve the system.

“Robert Petricek, who was the head of CMS at the time, knew about a local wine producer that was using RFID to track its bottles,” said Robert Selvey, former manager of the Industrial Hygiene group. (Both Petricek and Selvey are now retired from Brookhaven Lab.) The two talked often about how RFID could be used to solve Brookhaven’s CMS challenges.

An RFID tag is basically a small chip with an antenna that’s stuck to the side of whatever item you wish to track. But the Lab’s CMS team discovered that what worked on wine bottles wouldn’t work on the Lab’s chemical inventory. Although an RFID tag does not need to be within a scanner’s line of sight—and can even be embedded in a tracked object—some container materials and chemicals themselves blocked the signal. The team needed to find a way to overcome this limitation before committing to an expensive and time-consuming Labwide program.

“We came into Bldg. 480 and we practiced and learned how to do RFID really, really well before we invested money in upscaling,” Selvey said. “We found out a lot of things in that preliminary stage and got a lot of our initial $50,000 investment.”

And, as Selvey recalled, they innovated.

“We invented what’s now known as the BNL Flag Tag,” he said. After many rounds of testing, Selvey, Petricek, and the team learned that by placing an RFID tag on the container surface at a right angle, sticking out, instead of flat, then the scanner could read it.

“And so, this [flag] is a BNL innovation that other laboratories have since adopted a lot,” he noted.

Piloted, Implemented

They moved ahead with a pilot study in 2013, and then by 2015 felt confident enough to move forward with the Lab’s entire chemical inventory. The switch to RFID tagging for all chemicals took about two-and-a-half years.

“This enables us to take a chemical inventory in an area within a matter of minutes, instead of hours,” said Melissa Longpre, a former member of the CMS team and a team lead in the RFID tagging effort. “A scientist or space manager who wants to check their inventory for accuracy doesn’t need to halt all other activity in a lab. We can find chemicals in a lab full of hundreds, if not thousands, of containers. And we can do simple transactions using the scanners while we're in the field.”

And while the program was implemented, the team came across old legacy chemicals, which were taken by Waste Management for proper disposal, making the entire Lab safer.

It’s Popular

Longpre said some scientists have found the RFID tag system so useful, they’ve purchased their own scanners to use in their labs.

“If a scientist has hundreds of chemicals in their name, they can use our six-digit unique RFID barcode number assigned to each of the chemicals on site, to track and identify their inventory,” she said. “They simply type the information into the scanner, and within minutes—if not seconds—they find what they need.”

Dmitry Polyansky, a chemist in the Artificial Photosynthesis Group, said the time savings alone are worth the cost of a scanner.

“In some rooms where you have shelves upon shelves of chemicals, you can take the scanner and, with the push of the button, you have your inventory within less than a second,” he said. “You know what the chemicals in the area are, and it really sheds off at least 10, 15 minutes of your time.”

Safety Innovation Beyond RFID

With the RFID flag tag, the CMS team saw an additional opportunity for safety.

“On the backside of each tag, we just had a white field,” Selvey said. “And so we thought, ‘Hey, let’s use the back of this tag to color code it.’”

So along with RFID tracking, the Brookhaven Lab CMS has a color-coding system for hazard identification.

As the chemicals are delivered to the Receiving warehouse, a CMS team applies the RFID tag, which places all the data into the CMS database, including the primary hazard details.

“Basically, we assigned specific colors to specific hazard groups,” Longpre explained. “For example, we made red stickers for the flammable liquids, and we made yellow for the oxidizers, and so on.” Now, laboratory staff can know how their chemicals can be stored based on color class—which ones can be near each other on a shelf and which must be stored separately, or under special conditions.

CMS, RFID, and the Safe Conduct of Research

Linda Bowerman, the Environment, Safety & Health/Operations Manager for the Environment, Biology, Nuclear Science, and Nonproliferation Directorate, noted how the successful implementation of the RFID program demonstrates a commitment to Brookhaven's Safe Conduct of Research.

“The Safe Conduct of Research principles are something we take to heart at BNL,” Bowerman said. “And ‘SCOR’ principle number one is ‘everyone is responsible for safe operations.’ The researchers now have the ability to look at their chemicals via the inventory. If they can't find something, they can use the CMS RFID program to track items down more easily.”

Bowerman noted out how investment in the RFID program “really helps researchers, space managers, and the technicians who work with the chemicals feel that they have a better way of identifying the hazards that they’re working with.”

“The idea of Bob Petricek and Bob Selvey to look at a technology from one industry and apply it to the Lab was extraordinary,” said SHSD Manager Michael Clancy. “Their effort to pursue the idea, and carry out labeling tens of thousands of chemical bottles, has made the Laboratory a safer and more efficient organization.”

Learn more about Brookhaven Lab’s CMS.

2020-17452 | INT/EXT | Newsroom