Characterizing the Corrosivity of Nuclear Reactor Materials with Trishelle Copeland-Johnson

interview with a CFN user

January 24, 2022

Trishelle Copeland-Johnson is the Glenn T. Seaborg Distinguished Postdoctoral Fellow at Idaho National Laboratory and the Users’ Executive Committee (UEC) chair at the Center for Functional Nanomaterials (CFN). She is a materials engineering researcher specializing in optimizing the performance of materials in order to understand how materials’ properties relate to their performance. Some of the many applications of this approach are biomaterials for therapeutic treatments for cartilage, developing better thin-film deposition techniques for solar energy technologies, and – her current area of research – assessing corrosion performance of structural materials in molten salts. She holds a doctorate in Materials Science and Engineering from Iowa State University, a Masters of Chemical Engineering from the University of Delaware, and a B.S. in Chemical Engineering from the University of South Florida.

What kinds of materials are you currently studying?

My current research is focused on studying alloys for use in molten salt reactors, which employ molten (liquid) salts as the primary coolant and sometimes also as the medium to dissolve the fuel. This reactor design has been around since the 1960s but is gaining traction as a better way to look at nuclear energy. Molten salt reactors have some advantages over conventional nuclear reactors in terms of performance but we want to make them even safer by finding materials that perform better.

We are studying materials that are better choices for the reactor infrastructure. We’re looking at nickel (Ni) based alloys; specifically, how corrosion on these materials, which is inevitable, affects their performance.

How could your work help to improve these reactors?

One of the current challenges faced by nuclear power plants of this type is that the materials that are traditionally used undergo high rates of corrosion. We are looking at the type of oxidation that occurs on the surface of these alloys and how it affects how they hold up during operating conditions. The goal is to expand our knowledgebase of corrosion performance in molten salts. We also want to expand the types of materials that can be used in these reactors, since the number of alloys that have been fully assessed for use in constructing molten salt reactors is limited. Enhancing the fundamental knowledge base of these alloys will ultimately aid in enhancing the materials’ operating lifetime.

What tools and approaches do you use in this work?

My group and I use a suite of advanced characterization techniques. These include powder x-ray diffraction, both conventional approaches and synchrotron-based, spectroscopy, and electron microscopy.

What has been your overall impression of the U.S. Department of Energy (DOE) national laboratory system, given your extensive experience working within it?

I have interned at two national labs, Oak Ridge National Laboratory and Ames Lab. And I’ve done research at Brookhaven Lab – at two DOE Office of Science user facilities, CFN and National Synchrotron Light Source II (NSLS-II) – and am currently employed by Idaho National Laboratory. So I have spent a lot of time working within the national lab system. Being a researcher in that context does require patience, persistence, and the ability to delegate tasks to others, since it is a very complex infrastructure. But, that infrastructure grants us the ability to pursue complex and challenging research, which may not be feasible elsewhere and has a broad impact on the world’s population. My two internships were valuable because they allowed me to better figure out what research I wanted to pursue.

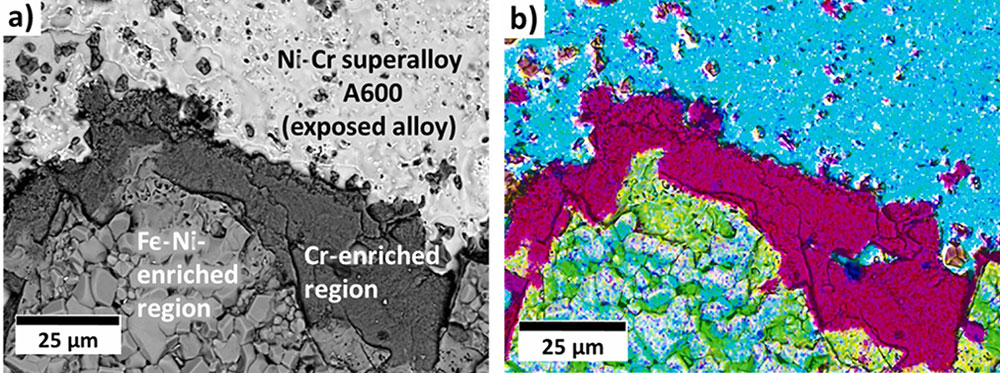

Scanning electron microscope (SEM) images (a) of the surface of the nickel/chromium (Ni/Cr) "superalloy" that Copeland-Johnson studied as part of her thesis research, with the shading representing different elements, and (b) the same image with colors representing the elements (Trishelle M.Copeland-Johnson, et al. Corrosion Science 195 (2022) 109950).

The CFN and NSLS-II are DOE Office of Science User Facilities.

Interested in becoming a CFN user? Submit a proposal through the online proposal system. The next deadline is January 31. If you have questions about using CFN facilities or partnering with CFN scientists, please contact CFN Assistant Director for Strategic Partnerships Priscilla Antunez at (631) 344-6186 or pantunez@bnl.gov.

Brookhaven National Laboratory is supported by the U.S. Department of Energy’s Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit https://energy.gov/science.

Follow @BrookhavenLab on Twitter or find us on Facebook.

2022-19381 | INT/EXT | Newsroom