Meet Guimei Wang, NSLS-II Accelerator Coordination Manager & Problem-Solver

Wang leads the group that collaborates with various experts within NSLS-II to ensure that the photons are delivered reliably and smoothly

March 15, 2024

enlarge

enlarge

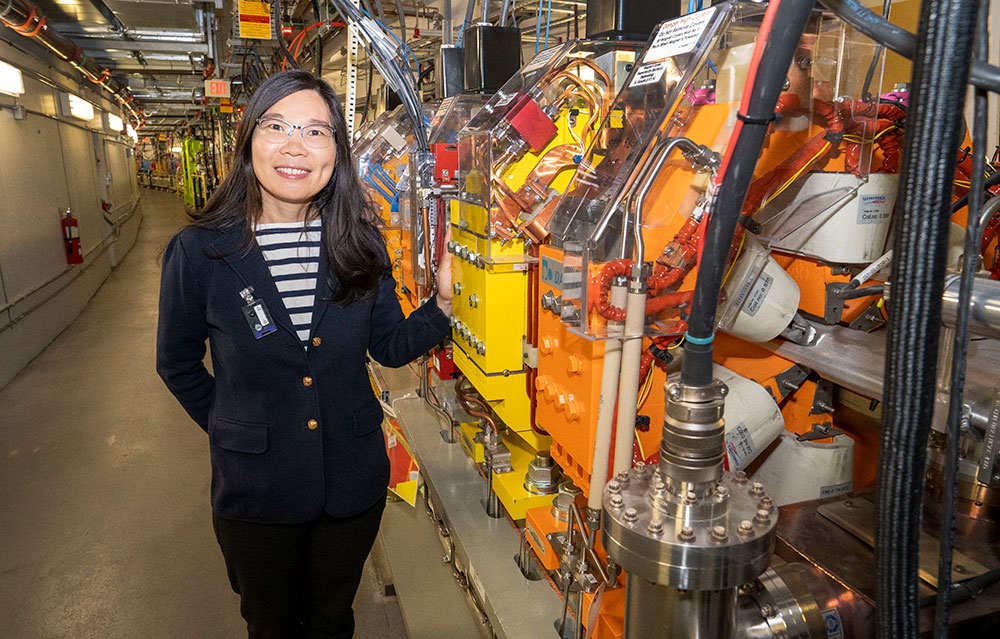

Guimei Wang standing next to the powerful magnets in the NSLS-II storage ring that steer, stabilize, and store electrons racing around at near light speed. (David Rahner/Brookhaven National Laboratory)

Guimei Wang is the leader of the Accelerator Coordination Group at the National Synchrotron Light Source II (NSLS-II), a U.S. Department of Energy (DOE) Office of Science User Facility located at DOE’s Brookhaven National Laboratory. NSLS-II produces ultrabright beams of light, from infrared to x-rays, that scientists use to study a wide range of materials and biological samples.

What kind of work were you doing when you arrived at NSLS-II?

I started my career at NSLS-II back in 2009, at the beginning of the facility’s construction. I was a postdoc at that time, and I was working on the optics design and beam dynamics of the injector, which keeps the storage ring supplied with a high-energy, high-quality electron beam. Then, in 2012, NSLS-II entered the beam commissioning stage, which was a very exciting journey; it was great to contribute to the design of the accelerator complex facility and witness the evolution of the facility from concept, simulation, and paper drawings to routine operation for user experiments. Following the success of the injector commissioning, we moved to commissioning the storage ring. The experience I gained from my work on the injector helped me contribute to this process. Following that, I was appointed as the first-run coordinator for the storage ring commissioning. Later in my career, I moved to the Accelerator Coordination Group and was promoted to my current role as group leader.

Tell us about your current role.

One of my responsibilities is developing the beam studies schedule, which involves structuring approximately 1,500 hours per year of machine time and performing beam studies with my group, which consists of three scientists and a postdoc. During beam studies, we restore the accelerator following a long shutdown or a maintenance period and return the beam quality back to its normal operation state. My group also develops and implements new programs to enhance machine performance, such as achieving higher current, improving beam stability, and reducing beam emittance. We lead the commissioning of any new beamline's source and collaborate on studies with beamlines, such as how the electron beam emittance impacts beamline brightness or coherence.

In the event of an issue with the accelerator or abnormal beam quality at the beamlines, I am always the first point of contact. Our job is to diagnose the problem and address it as soon as possible. When a beamline reports an issue, we first check whether the issue is from the storage ring or the beamline itself. If the storage ring has a problem, we track down the root cause, which means pinpointing a particular subsystem. Then, we will reach out to the appropriate group and work with them. When it comes to troubleshooting, we play a central role among all the various groups.

Coordinating routine maintenance, which occurs every two or three weeks, is also part of my group’s responsibilities. All of these things require extensive cooperation with a variety of experts at NSLS-II.

What is your group’s approach to problem-solving?

Prevention is the first step. Routine accelerator maintenance, just like routine car maintenance, is very important. These regular tune-ups truly make a big difference. In the early years of NSLS-II, we often had to do off-hours problem-solving—we were on call 24 hours a day, year-round. We still are, but over time we have developed the tools and prevention tactics to make these situations easier and happen less often. We’ve been able to get to this point because of the knowledge base we’ve built over time. Whenever there is a problem, we review the issue and develop a work plan to prevent the same thing from happening again. With those lessons learned, and regular maintenance, we don’t have the same frequency of problems as we did in the early days. Every group in the NSLS-II Accelerator Division takes their responsibilities very seriously.

Another part of our job is to develop software-based tools to make operation and beam studies easier and to help us diagnose machine issues. We also write procedures and provide training that is easy for operators to follow. This part of our work helps the team greatly because multiple individuals can be qualified to work on the machine, which is more efficient when problems arise.

The problems we address vary in complexity; some are straightforward, while others can be very complex. Potential sources of the problem can come from multiple systems, such as an issue between the injector and the storage ring, for example. This could come from bad beam quality in the injector, an issue with the performance of the storage ring injection kickers, or even obstacles along the beam path. The symptoms could either be directly related to the root cause or an outcome of a problem with another system. Like a doctor treating a patient, our task is to identify the root cause to prevent its recurrence. Once the root cause is identified, we develop a work plan and procedure to minimize machine downtime.

By doing preventive maintenance, work planning, team cross-training, and using our powerful operations tools, we keep NSLS-II running reliably. Reliability is the top priority for a synchrotron user facility. NSLS-II runs seven days a week, 24 hours a day, for 5,000 hours per year, supporting thousands of user experiments. We target our reliability to be near 97% or above.

What do you like about your job?

I enjoy working with the great, diverse, and talented teams at NSLS-II to solve problems that impact users' experiences. Many users come from various states across the U.S. or even internationally, with reserved experiments in specific time windows. Our efforts directly influence beamline operation, and therefore the scientific outcomes of these experiments. These experiences of fixing problems are very rewarding.

The nature of some problems is that they are unpredictable, and you can’t plan for every scenario. Sometimes you don’t know the solution until you look for it. There can be pressure to solve an issue quickly. Once, for example, we were not able to inject the beam into the storage ring and it took hours to debug the issue. Situations like that can be very stressful, but having a talented team makes a significant difference. If I can’t find an answer right away, I bring the team to collaborate on the problem. Working together with experts from different backgrounds and perspectives is a very enjoyable process. I have learned a lot from them during these collaborative efforts.

What is a typical challenge that you face in your role?

The most common problem I encounter is beam instability, which can be caused by a number of factors, like external vibrations. Something like this can come from an unstable power supply system or the utility system, which are everywhere and necessary for the operation of NSLS-II but can drive large noise levels at a certain frequency. We have about 200 beam position monitors located around the storage ring that allow us to monitor and pinpoint which area an instability comes from. Then, we work with experts to evaluate the subsystem's performance to better figure out what is causing it. Once we understand where the source of the motion is, we fix or minimize the source’s effects.

Another facet of this is the fast orbit feedback system, which is designed to correct the position of the beam and suppress vibrations by incorporating information from the beam position monitors.

Describe a specific challenge for us and how it was handled.

Some beamlines are more sensitive to beam instabilities than others. The Hard X-ray Nanoprobe (HXN) beamline, for example, can achieve world leading nanometer-scale resolution, but it is super sensitive to vibrations. We implemented a unified orbit feedback system with local photon feedback at HXN to stabilize the x-ray photon beam at the micrometer level.

Last year, there was a vibration at a frequency of 35 hertz that strongly affected HXN users’ experiment. We used our diagnostic tools and could not see that specific frequency showing up in the storage ring electron beam. Ultimately, we worked together with the beamline staff and figured out it was coming from the beamline optics and the root source was the utility system at HXN.

What are some activities you enjoy outside of work?

I like to go hiking and just be outside in nature with my family. I am married and have two sons, Eric, who is 14, and Charles, who is 11. We like to go upstate and visit places like Bear Mountain State Park in the Hudson Highlands. It’s a beautiful area, and we go there a few times a year. My family and I also enjoy walking the Setauket-Port Jefferson Station Greenway Trail. It’s a good two or three hours of walking, and at the end of the trail there is a delightful spot to get ice cream.

Another hobby I enjoy is yoga, which led me to join Brookhaven Lab’s yoga club. Because I sit in front of a computer so much, I find that yoga is very helpful for shoulder or back pain.

I also like to go fishing. When I was young, I would always go fishing with my dad. We would spend a whole day at the riverside, and those are special memories. I still like to go fishing. In the summer, my family and I often go to the ocean or a lake, such as Stump Pond in Smithtown, here on Long Island, to enjoy quiet moments and spend good quality time together.

Brookhaven National Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit science.energy.gov.

Follow @BrookhavenLab on social media. Find us on Instagram, LinkedIn, X, and Facebook.

2024-21719 | INT/EXT | Newsroom