Insights into Preceramic Polymer-Based Inks for 3D Printing

December 11, 2024

enlarge

enlarge

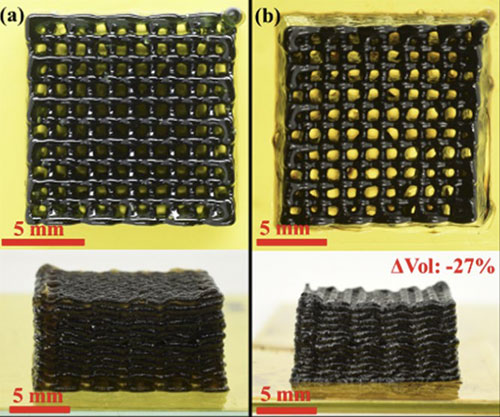

Images of (a) the top and side view of a sample printed using a PCP/PCPGNP mixture and (b) the same sample, thermally-treated. Credit: Science ACS Appl. Eng. Mater. 2024, 2, 10, 2379–2390.

The Science

A commercial preceramic polymer (PCP) dispersed with PCP-grafted nanoparticles (PCPGNPs) was shown to have more desirable properties than PCPs alone.

The Impact

PCP/PCPGNP mixtures are an underexplored, promising route to better feedstocks for 3D printing, and ultimately the creation of better 3D-printed products.

Summary

Preceramic polymers (PCPs) are a class of polymers that can be converted into ceramic compounds through the process of pyrolysis, a heat treatment used to induce chemical changes in a material. The preceramics can be processed in multiple ways, such as into fibers, thin films, and complex shapes, and the resulting ceramics have high thermal and chemical stabilities. They have the potential to make excellent feedstocks for the inks used in 3D printers.

However, there are challenges to overcome. For example, the ceramics can experience volume shrinkage and loss of mass during pyrolysis, leading to pores and cracks. One potential fix is to combine PCPs with PCP-grafted ceramic nanoparticles (PCPGNPs), but this approach has not been thoroughly explored.

In this study, researchers studied a PCP/PCPGNP system using a rheological approach, which focused on measuring the material’s flow and deformation characteristics. They used a commercially available PCS, known as SMP-877, that was dispersed with silica nanoparticles grafted with a silicon-based polymer.

The group studied the effect of increasing concentrations of PCPGNPs on the system’s behavior. Among their findings was that some of the mixtures — those with concentrations above a critical “percolation threshold” — displayed higher viscosities and rapid shear thinning, a property in which a material reversibly becomes more like a liquid when pressure is applied. These samples also responded better to the heat treatment. Overall, the samples showed promise for direct-write 3D printing applications.

The rheology results were corroborated with X-ray photon correlation spectroscopy studies, which were performed at the Coherent Hard X-ray Scattering (CHX) beamline at National Synchrotron Light Source II (NSLS-II). NSLS-II is a U.S. Department of Energy (DOE) Office of Science user facility located at DOE’s Brookhaven National Laboratory.

This work was conducted by researchers from the Florida A&M University-Florida State University College of Engineering, the Air Force Research Laboratory, and Brookhaven National Laboratory. It was led by FAMU-FSU engineering PhD student Gary Germanton, whose work is partially supported by a grant from the U.S. Department of Defense.

Download the research summary slide (PDF)

Contact

Matthew B. Dickerson

Air Force Research Laboratory

matthew.dickerson.6@us.af.mil

Subramanian Ramakrishnan

FAMU-FSU College of Engineering

srama@eng.famu.fsu.edu

Publications

Gary Germanton, Kara Lindsey Martin, Md Alamgir Hossain, Nicholas Dunn Posey, James F. Ponder Jr., Camilo Ramirez, Pitchaimari Gnanasekar, Lutz Wiegart, Pavan Polisetty, Daniel T. Hallinan Jr., Matthew B. Dickerson, Subramanian Ramakrishnan. "Insights into Preceramic Polymer-Based Additive Manufacturing Inks via Rheological and Scattering Studies of Preceramic Polymer-Grafted Nanoparticles Suspended in Polycarbosilane." ACS Applied Engineering Materials 2024, 2, 10, 2379–2390.

DOI: https://doi.org/10.1021/acsaenm.4c00411

Funding

The authors declare no competing financial interests. The authors gratefully acknowledge funding from the Air Force Research Laboratory and Air Force Office of Scientific Research (AFOSR). We would like to thank Dr. Ming-Jen Pan, the program officer for the Aerospace Composites Portfolios, for his support of our research. Research was performed by UES employees (K.L.M., N.D.P., J.F.P.) on site at AFRL/RX under contract FA8650-21-D-5279. S.R., M.A.H., and C.R. would like to acknowledge funding from the Department of Defense proposal agreement number W911NF2320222. P.G. would like to acknowledge funding from Department of Defense proposal agreement number W911NF2310172. G.G. was supported by the Department of Defense through the National Defense Science and Engineering Graduate (NDSEG) fellowship program and would also like to acknowledge partial support from the AFRL-MLRCP program. D.T.H. would like to acknowledge support from AFOSR grant number FA9550-23-1-0288. This research used resources and the Coherent Hard X-ray Scattering (CHX, 11-ID) beamline of the National Synchrotron Light Source II, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Brookhaven National Laboratory under contract no. DE-SC0012704. Distribution A: Approved for public release: distribution unlimited.

2024-22286 | INT/EXT | Newsroom