Advanced Heating Technologies Show Potential

March 21, 2014

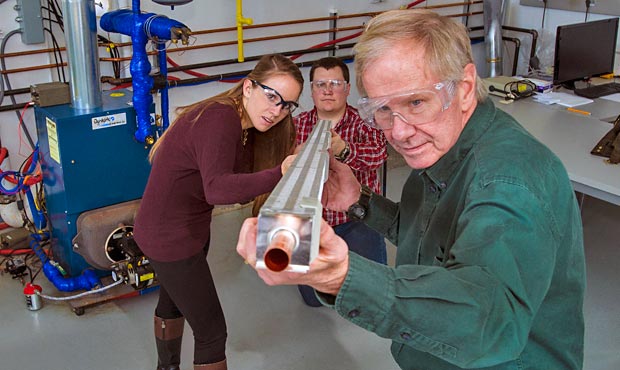

Tom Butcher, right, and team members Rebecca Trojanowski and Chris Brown examine a length of the fin-tube heat exchanger the team will study.

The New York State Energy Research and Development Authority (NYSERDA) recently selected several Brookhaven Lab projects aimed to develop advanced technologies for more energy-efficient buildings. Tom Butcher and his Energy Conversion Group from Brookhaven Lab’s Sustainable Energy Technologies Department will collaborate with Stony Brook University and several private companies on this work.

“In the interest of getting to higher efficiency levels in heating systems, water temperatures are getting colder, making boilers more efficient in the steady state and also reducing their idle losses,” Butcher said.

In the past, he explained, heating systems were designed based on 180 degree water temperature. To increase efficiency, that’s being reduced to as low as 120 degrees depending on weather conditions. The common, inexpensive baseboard radiator is widely used across the United States, but has a problem being compatible with this practice because energy output falls off very strongly as the water temperature decreases. Butcher’s team aims to improve the low temperature performance of baseboard radiators by supplementing the buoyancy-driven flow with a forced convection flow.

In another heating systems project, Brookhaven Lab collaborators will work to develop a low-cost, corrosion-resistant heat exchanger for a high-efficiency steam boiler using thermally conducted polymers. “As these systems get higher in efficiency, they reduce the exhaust gas temperature. The condensate that’s formed is corrosive because of the acids associated with the combustion process,” Butcher said. “That leads to the use of more expensive alloys for those heat exchanger materials. We’d like to eliminate or reduce that high cost through the use of polymer heat exchangers. Polymers for heat exchangers traditionally have low thermal conductivity. To overcome that, we’re interested in the use of filler materials, including nanomaterials, to increase the conductivity of the polymers.”

To learn more about these projects visit: http://www.bnl.gov/newsroom/news.php?a=24484

2014-4735 | INT/EXT | Newsroom