3D Printing in High Demand

January 20, 2015

Leo Reffi stands in front of the 3D printer in Building 743

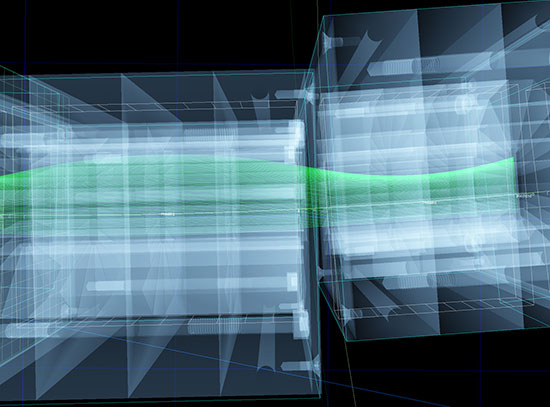

It looks like a coffee dispenser. But the nondescript grey box tucked against a wall in Building 743 is actually a 3D printer. It’s in high demand by scientists and engineers building beamlines for Brookhaven Lab’s National Synchrotron Light Source II (NSLS-II).

“They use it to test their ideas before committing to final designs,” said mechanical designer Leo Reffi, who controls the print jobs.

A 3D printer makes solid objects from digital designs. You choose the design, send it to the printer, and click on the “make” button. The machine heats up a slender filament of material until it melts, then puts down very thin layers in the shape of the object. The process is additive – the printer deposits material layer upon layer to build up the object. This can take hours or days depending on the size and complexity of the object.

While Brookhaven’s industrial setting requires these printers – the Instrumentation Division uses them for work on the Large Synoptic Survey Telescope and Central Fabrication Services has one – the Lab’s Science Learning Center is using 3D printers for a course with teachers and students (see below) to remain on the cutting edge of technology.

Full story: www.bnl.gov/newsroom/news.php?a=25416

2015-5491 | INT/EXT | Newsroom