Technologies Available for License

Categories: advanced materialselectronics & instrumentation

2019-006: Inorganic-infiltrated polymer hybrid thin film resists for advanced lithography

Invention: 2019-006

Patent Status: U.S. Patent Number 121,408,652 was issued on November 12, 2024

For technical and licensing related questions, email tcp@bnl.gov.

Summary

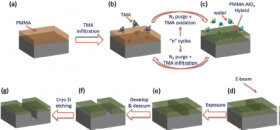

A schematic representation of the process flow (a) PMMA 950 A2 was spin coated on cleaned Si substrates at 7500 rpm for 60 s resulting in a B60 nm thick PMMA film. During the infiltration process alternating half-cycles of (b) TMA infiltration and (c) water infiltration are repeated for a given number of times in order to synthesize the ex situ processed hybrid resist composition. The sample with the hybrid resist is then subjected to e-beam exposure (d); and the resulting modified resist with specific patterned areas (e) is then developed in a 1 : 3 MIBK : IPA solution for 45 s followed by 15 s IPA rinse to acquire the patterned substrate (f). After an appropriate descum process, the patterned substrate is then subjected to the cryogenic Si etch process at minus 100 degree centigrade using a combination of SF6O2 gas mixture to transfer the pattern to the Si substrate (g).

Lithography-based patterning has been instrumental in the realization of the immense computational power possessed by modern day computers. In order to meet the continued growing requirements of patterning smaller and smaller linewidths at high throughput, continuous advances in the lithography techniques are essential. Extreme ultraviolet (EUV) lithography, is one such advancements being implemented for high volume manufacturing. However, the resists for EUV lithography pose rigorous requirements such as high optical absorption, high etch resistance, high sensitivity and resolution as well as low line edge roughness (LER). The traditional candidates, such as Chemically Amplified Resists (CARs) do not meet these necessities. Metal containing organic-inorganic resists are being investigated to meet these needs. Studies have shown that these resists depend heavily on optimizing complex chemical synthesis and require establishment of new infrastructure. Moreover, the limited shelf-life of these resist materials also possess restriction on their long-term use. This Brookhaven technology relies upon infiltrating required metals as well as their oxides into the thin films of resist material such as poly(methyl methacrylate) (PMMA) by vapor phase infiltration to synthesize hybrid nanocomposite resist with enhanced properties. The synthesized hybrid resists can then be subjected to the lithographic patterning and subsequent pattern transfer.

Description

This Brookhaven method relies upon infiltrating required metals, including but not limited to Al, Zn, Sn, Ti,Zr, Hf, In, Sb, Co, Ni, Pd, W, Pt, Au etc., as well as their oxides into the thin films of resist material (including but not limited to poly(methyl methacrylate) (PMMA) and similar acrylate based resist derivatives, ZEP series, CSAR series, polystyrene derivatives, poly(2- vinylpyridine) derivatives) to synthesize hybrid nanocomposite resist with enhanced properties. The infiltration of the metal or metal oxide can be carried out by vapor phase infiltration using the tools including but not limited to atomic layer deposition chamber and/or by liquid-based infiltration using solutions of metallic salts. The synthesized hybrid resists can then be subjected to the lithographic patterning and subsequent pattern transfer. As a proof of concept study, the Brookhaven researchers have developed organic-inorganic hybrid resists by utilizing infiltration synthesis of AlOx into spin-coated thin films of a commonly used resist, PMMA. The results have been published and the insights gained from the study contribute to developing novel hybrid nanocomposite resist platform for next generation lithography without the need for complex synthesis chemistry.

Benefits

The Brookhaven method provides an improved cost effective procedure to prepare organic-inorganic hybrid resist materials for use in advanced lithography techniques. Unlike other approaches this method neither requires heavy optimization of complex chemical synthesis nor the establishment of new infrastructure.

Applications and Industries

Method to prepare organic-inorganic hybrid resist materials for advanced lithography for the semiconductor industry.

Journal Publication & Intellectual Property

- Advancing next generation nanolithography with infiltration synthesis of hybrid nanocomposite resists (.pdf)

- US 12,140,865 B2 (.pdf)

Tags: device

Contacts

-

Poornima Upadhya

Manager Technology Transfer & Commercialization

Technology Commercialization

(631) 344-4711, pupadhya@bnl.gov

-

Avijit Sen

IP Licensing & Commercialization

Technology Commercialization

(631) 344-3752, asen@bnl.gov