Technologies Available for License

Categories: advanced materialselectronics & instrumentation

2015-016: Alkali Antimonide Thin Films and Photocathodes

Invention: 2015-016

Patent Status: U.S. Patent Number 10,049,848 was issued on August 14, 2018

For technical and licensing related questions, email tcp@bnl.gov.

Summary

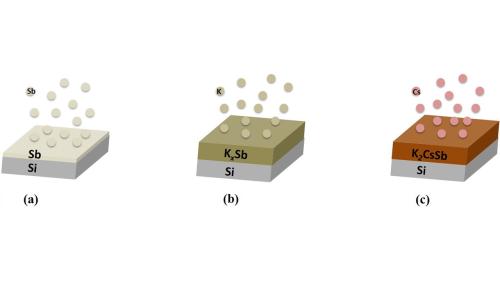

Schematic diagram shows the diffusion process of the K2CsSb photocathode: (a) Sb thin film deposition; (b) K diffusion forming a KxSb compound; and (c) Cs diffusion forming a K2CsSb photocathode.

Alkali antimonides have found extensive use in photodetectors and image intensifiers. However, these materials are inherently rough when grown through traditional sequential deposition; this roughness has a detrimental impact on the intrinsic emittance of the emitted beam. Sputter deposition may provide a path to achieving a far smoother photocathode, while maintaining reasonable quantum efficiency. In this invention Brookhaven and Berkley lab researchers described the creation of alkali antimonide films, and its use to create photocathodes, and photodetectors with high quantum efficiency. The key aspects for fabricating alkali antimonide thin films process includes, i) use of an alkali (especially Cs) to promote crystallization of an alkali antimonide film produced via sputter deposition, and ii) introduction of a deposition system consisting of a sputter source and an alkali evaporator. This device would permit the deposition of alkali material after sputtering was complete, without contaminating the sputtered film or the target.

Description

For successful stoichiometric growth of K2CsSb, the sputter source was operated at 10 W power, with a silicon substrate held at 120 0C. The substrate had been HF dipped and baked to 500 0C prior to growth. The sputter gun was cleaned via operation at 20 W onto a mask. The sputtering chamber was held at 20 m Torr of argon atmosphere. The material was observed via both in-situ X-ray florescence detector (XRF) and in-situ X-ray powder refraction detector (XRD) during growth, and while the stoichiometry was correct for K2CsSb (via XRF), the material did not crystalize (via XRD). After sputtering 50 nm film thickness, the film was observed to be very smooth via X-ray reflectivity detector (XRR) - far smoother than evaporated films. However, the photo response was poor. Subsequent evaporation of Cs onto this film catalyzed crystallization throughout the film, and lead to a good photo response, with a peak quantum efficiency (QE) of 12% at 350 nm.

Benefits

While significant room remains to optimize the growth processes of these cathodes, sputter growth of alkali antimonides appears to be a path toward much smoother high-QE cathodes.

Applications and Industries

One of the main applications of this invention is to provide a system and method for delivering photocathodes with high quantum efficiency. Among various photocathode materials, alkali antimonides, such as K2CsSb has a great promise in the application of future light sources because of their high QE, fast response time and low thermal emittance.

Journal Publication & Intellectual Property

Contacts

-

Poornima Upadhya

Manager Technology Transfer & Commercialization

Technology Commercialization

(631) 344-4711, pupadhya@bnl.gov

-

Avijit Sen

IP Licensing & Commercialization

Technology Commercialization

(631) 344-3752, asen@bnl.gov