Technologies Available for License

2024-007: Fluidics Technology for Efficient Autonomous Synthesis

Invention: 2024-007

Patent Status: Application Number US20250229247A1 was published on July 17, 2025

For technical and licensing related questions, email tcp@bnl.gov.

Summary

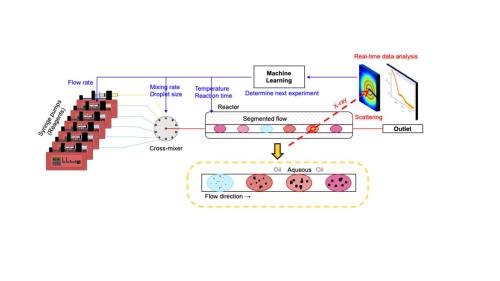

Scheme: Autonomous fluidic platform for gold nanoparticle synthesis and characterization with machine learning.

Describes a high-throughput self-driven microfluidic platform for on-the-fly autonomous synthesis of target nanoparticles or other materials. Integrated with in-situ characterization, real-time data processing, and artificial intelligence, the platform can make real-time decisions and plan experiments, enabling efficient and rapid exploration of a vast set of synthetic possibilities. Features of the platform include a modular construction, droplet fluidics design and flow path, and reactor design, allowing for parallel synthesis and adaptability for advanced X-ray and other spectrometric analyses. This platform may provide in-depth insights for wet-chemistry synthesis processes. As a proof-of-concept autonomous synthesis of gold nanoparticles is described where the size distribution of gold nanoparticles is shown to be optimized rapidly and efficiently by performing a minimal number of experiments.

Description

The self-driven microfluidic platform integrates automation, in-line analytics, and AI-driven active learning. The real-time data analysis software, coupled with a Gaussian process machine learning model, not only furnishes instantaneous feedback throughout the target nanoparticles synthesis process but also expedited and enhanced the nanoparticle discovery and optimization. The workflow for autonomous nanoparticle synthesis (scheme) consists of four major parts: (1) The automated droplet generation, (2) in-situ X-ray characterization, (3) real-time data processing & analysis, and (4) machine learning.

Benefits

The high-throughput self-driven microfluidic platform offers many technical and economic benefits including high precision and control in mixing chemicals, modular design for easy extension, remote access of synthesis process, increased productivity due to automated synthesis and optimization, reduces the need for extensive trial-and-error experimentations leading to substantial cost savings in materials and labor, etc.

Applications and Industries

The proposed system can be utilized in a wide range of research and industrial arena including pharmaceutical and biotech industries, chemical manufacturing plants, academic and research institutions, electronics and semiconductor industries, etc.

Journal Publication & Intellectual Property

- US 2025/0229247 A1 (.pdf)

- Quantifying dispersity in size and shape of nanoparticles from small-angle scattering data using machine learning based CREASE (.pdf)

- Flexible formulation of value for experiment interpretation and design (.pdf)

- Autonomous Nanoparticle Synthesis Guided by In Situ Multiscale Structural Characterization (.pdf)

Contacts

-

Poornima Upadhya

Manager Technology Transfer & Commercialization

Technology Commercialization

(631) 344-4711, pupadhya@bnl.gov

-

Avijit Sen

IP Licensing & Commercialization

Technology Commercialization

(631) 344-3752, asen@bnl.gov