Technologies Available for License

Categories: advanced materialsnanotechnology

2023-013: High Performance Membranes for Gas Separation

Invention: 2023-013

Patent Status: Application Number WO2025111491A1 was published on May 30, 2025

For technical and licensing related questions, email tcp@bnl.gov.

Summary

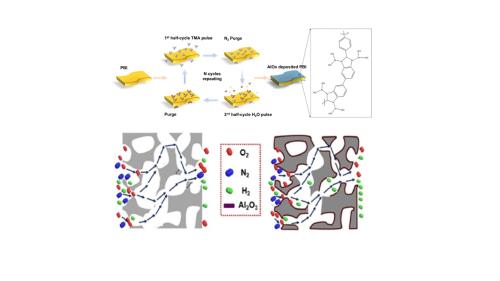

Schematic diagrams of the synthesis process AlOx layer on PBI films via atomic layer deposition and membrane function.

In this joint invention, researchers from Brookhaven with Stony Brook University and University at Buffalo provide a facile and scalable way of engineering polymeric membranes at a sub-nanometer level to improve its gas permeability and/or gas enrichment functions. Atomic layer deposition (ALD) treated polymer polybenzimidazole (PBI) showed increased H2 permeability by 120%-270% and H2/CO2 selectivity by 30% at 35-200oC.

Description

Few-cycles of ALD can be used to engineer functional polymers at a sub-nanometer scale to improve both molecular size-sieving ability and counterintuitively, gas permeability. Specifically with just one cycle of ALD for polybenzimidazole (PBI-1C) by sequential exposure to trimethylaluminum (TMA) and water vapor remarkably increased its H2 permeability and H2/CO2 selectivity. The ALD treatment deposits an AlOx layer on the surface and also enables the TMA to infiltrate and react with the bulk PBI to form an AlOx network, disrupting polymer chain packing and increasing chain rigidity. One ALD cycle remarkably increased pure-gas H2 permeability by 270% from 2.3 to 8.4 Barrer while retaining H2/CO2 selectivity of 12 at 35oC, and increasing the temperature from 35 to 200oC increases H2 permeability of PBI-1C by more than on order of magnitude to 110 Barrer and H2/CO2 selectivity by 58% to 19. The PBI-1C also exhibits stable H2/CO2 separation performance when challenged with simulated syngas containing water vapor up to 200oC, overcoming the permeability/selectivity tradeoff for H2/CO2 separation.

Benefits

The thermally stable membranes described here have high H2 permeability and high H2/CO2 selectivity. This membrane technology has the potential to offer a low cost and energy efficient hydrogen purification and CO2 capture for fossil fuel derived power plants. Additionally, unlike the conventional absorption or adsorption technology operating near ambient temperatures, the ALD-engineered membranes are robust and can operate at the syngas processing temperature (150°C).

Applications and Industries

Generally this invention holds the promise for improving membrane technologies in energy, environmental, and industrial applications. Specifically, the technology can be used in, i) hydrogen purification and CO2 capture in hydrogen production plants and power plants; ii) hydrogen recovery from refinery off-gas and natural gas liquid production; iii) hydrogen recovery from mixtures with nitrogen in ammonia plants; iv) hydrogen removal from syngas for methanol plants, and v) hydrogen separation from mixtures with helium, etc.

Journal Publication & Intellectual Property

Contacts

-

Poornima Upadhya

Manager Technology Transfer & Commercialization

Technology Commercialization

(631) 344-4711, pupadhya@bnl.gov

-

Avijit Sen

IP Licensing & Commercialization

Technology Commercialization

(631) 344-3752, asen@bnl.gov