Technologies Available for License

Categories: electronics & instrumentationnanotechnology

2024-006: Design of Complex 3D Materials with DNA Nanotechnology

Invention: 2024-006

Patent Status: Non-Provisional filed on December 13, 2024

For technical and licensing related questions, email tcp@bnl.gov.

Summary

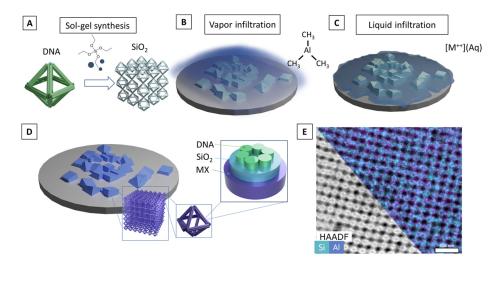

Figure: Inorganic templated structures. (A) A silica 3D framework is formed when a lattice of DNA frames is coated with a layer of silica grown via sol-gel synthesis. Templating of the framework is achieved either by (B) VPI, where a vapor precursor such as TMA infiltrates the silica framework, or (C) LPI, whereby metal salt solutions infiltrate the nanolattice structure. (D) The resultant nanolattice after heat treatment is composed of conformal coatings of silica and metal/metal oxide (MX) on a DNA scaffold. (E) Scanning TEM (STEM) cross-sectional HAADF imaging and EDS map of silica (blue) coated with alumina (purple) via vapor infiltration. Scale bar, 100 nm.

Controlling the 3D arrangement of inorganic materials is essential for unlocking new mechanical, optical, and electronic properties in various applications. In this joint invention, researchers employed programmable self-assembly properties of DNA to guide the creation of organized 3D structures of inorganic materials at the nanoscale. The DNA served as a structural template, allowing the inorganic materials to form in an ordered manner that follows the DNA's framework. By using liquid and vapor-phase infiltrations to fill the DNA frameworks, nanofabrication of diverse classes of inorganic frameworks from metal, metal oxide and semiconductor materials as well as their combinations were demonstrated.

Description

DNA origami frames are formed from the folding of a long scaffold strand of M13 phage DNA with many short synthetic strands of complementary DNA. Following synthesis of the origami precursor, the DNA frames with complementary binding strands, placed at their vertices, were mixed together and annealed from 50°C to room temperature at a rate of -0.2°C/hour to form 3D DNA frameworks. Sol-gel wet chemistry was used to grow a 4-to 10-nm-thick layer of silica on the DNA bundles of each type of framework (Figure), thus forming silica replica of the DNA framework.

Benefits

The possibility to transfer a multitude of DNA-defined geometries to a large structural diversity of inorganic materials opens possibilities for generating open framework 3D nanostructures with optical, mechanical, electrical, and catalytic functions.

Applications and Industries

Figure: Inorganic templated structures. (A) A silica 3D framework is formed when a lattice of DNA frames is coated with a layer of silica grown via sol-gel synthesis. Templating of the framework is achieved either by (B) VPI, where a vapor precursor such as TMA infiltrates the silica framework, or (C) LPI, whereby metal salt solutions infiltrate the nanolattice structure. (D) The resultant nanolattice after heat treatment is composed of conformal coatings of silica and metal/metal oxide (MX) on a DNA scaffold. (E) Scanning TEM (STEM) cross-sectional HAADF imaging and EDS map of silica (blue) coated with alumina (purple) via vapor infiltration. Scale bar, 100 nm.

Journal Publication & Intellectual Property

Tags: DNAlithography

Contacts

-

Poornima Upadhya

Manager Technology Transfer & Commercialization

Technology Commercialization

(631) 344-4711, pupadhya@bnl.gov

-

Avijit Sen

IP Licensing & Commercialization

Technology Commercialization

(631) 344-3752, asen@bnl.gov