From Laboratory to Industry: Unlocking the Potential of Graphene

Brookhaven Lab and Graphene Laboratories collaborate to bring atom-thin material to the masses

April 8, 2013

Elena Polyakova

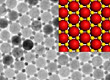

Graphene, the much-vaunted "super material" that catapulted onto the materials science scene just nine years ago, offers extraordinary opportunities for industries interested in everything from supercomputers to renewable energy. Unfortunately, graphene's singular characteristics come at the price of a challenging synthesis processes—weaving two-dimensional, atom-thin tapestries from carbon atoms requires considerable craft.

Armed with just such expertise, physicists Elena Polyakova and Daniel Stolyarov launched a company to provide laboratories and industry with much-needed samples of these remarkable hexagonal structures. Graphene Laboratories, based in Calverton, NY and founded in 2009, works in close collaboration with Brookhaven National Laboratory's Center for Functional Nanomaterials (CFN) to pioneer new synthesis techniques and characterization studies of graphene and other promising two-dimensional materials.

Daniel Stolyarov

With graphene rising in both prevalence and potential, these kinds of collaborations will help move breakthrough technologies beyond the lab and into everyday use. Polyakova, CEO of Graphene Laboratories, and Stolyarov, Chief Technology Officer, weighed in recently on the future of the field and the opportunities it offers.

What makes graphene such an exciting and worthwhile material, and how might it impact the public?

Polyakova: Some people are simply interested in the material's exciting fundamental properties, and that is certainly important. But for me, the potential for use in commercial devices is the biggest motivation to pursue graphene research. Modern economic challenges are a great reason to work with potentially disruptive technologies that can create new jobs and markets.

Stolyarov: There are extensive applications for graphene—from biology to space exploration—and the number of potential uses continues to grow. Graphene may be used as a transparent conductor and replacement for indium tin oxide in solar cells and touch-screen devices, offering superior flexibility and robustness. It could also replace silicon in the next generation of electronics, and its chemical sensitivity makes it useful as a detector. In fact, we are actively collaborating with scientists from Stony Brook University at Brookhaven's CFN to create new chemical sensors with graphene.

What makes graphene synthesis so challenging?

Polyakova: Graphene requires special equipment and expertise, which involves understanding how various subtle parameters affect both growth and quality. For example, precise conditions relating to the temperature, pressure precursor, and the quality of the substrate used all play an important role in the successful production of graphene by a process called chemical vapor deposition.

Daniel and I have done extensive research work, and it can take years to reach the level of knowledge we now possess. Other researchers, who don't need that synthesis expertise, are able to get the material from us and focus more fully on their own endeavors.

What attracted you to Brookhaven Lab's Center for Functional Nanomaterials?

Stolyarov: Graphene Labs has quite an extensive collaboration with CFN, including three active projects. Brookhaven Lab and CFN have offered an ideal partnership both because of the extraordinary facilities and the on-site expertise. Further, CFN is in an ideal location, within 15 minutes of Stony Brook University and our own offices. For us, all of these factors combine to make Brookhaven Lab the cornerstone of the Long Island high-tech community.

What specific capabilities equip CFN to help advance graphene technology?

Stolyarov: CFN has its own extensive graphene research program with all the equipment necessary to study this remarkable material. For example, Peter Sutter's Interface Science and Catalysis group developed a unique probe station that enables users to perform transport measurements at cryogenic temperatures under a high magnetic field.

I cannot overstate the value of the help we received from CFN scientist Fernando Camino. Not only does he understand the capabilities of the equipment, but he also has a broad background in nanotechnology and provided us with very useful insight many times. We also received help from many other CFN scientists, including Ming Lu, Aaron Stein, Chang-Yong Nam, and Dmytro Nykypanchuk.

Polyakova: I hope that scientists at CFN benefit from our collaboration as well. We provide them with insight into the challenges faced by industries as they unlock the commercial applications of novel materials. We may also expand upon the processes developed at Brookhaven Lab and translate it to an industrial scale.

How important are your scientific backgrounds to your current work as entrepreneurs?

Polyakova: My scientific background is essential in part because we produce many of our materials in-house, and also because knowledgeable customer support is a large part of our business model. Even as we grow and my role changes, it is still important for me to be able to help resolve any particularly challenging issues.

Beyond that, I am able to make informed decisions regarding where to take the company moving forward. Having a strong background in material science helps determine which direction to take a nanotechnology company.

There is a fairly steep learning curve to owning and managing a company, which includes knowledge of marketing, finance, taxation, web design and IT, legal issues, hiring and payroll, as well as managing employees. It is certainly a lot to digest, but I don't think it is nearly as steep as it would be for an MBA attempting to learn the science behind the materials.

Fortunately, here on Long Island, I have had the support of people like Monique Gablenz, Director of the Calverton Incubator, Anil Dhundale, Executive Director of Stony Brook's Incubator Program, and David Hamilton, Director of Business Development for the Clean Energy Business Incubator Program (CEBIP). Their combined assistance has been extraordinary.

Looking ahead, how do you see the industry and demand for these materials changing in the coming years?

Polyakova: I expect that the industry will move to large-scale manufacturing over the next 5 to 10 years as advanced materials are incorporated into commercial products. The market is still largely dependent on research groups at universities, but we are seeing a growing number of sales to major companies and graphene-related patents beginning to emerge. These companies will soon need large-scale suppliers, and there will be a lot of competition to fill those roles.

What about your company should excite the general public and Long Island in particular? Are there specific technologies on the horizon?

Polyakova: The clean-technology potential of these new materials should be of particular interest to the Long Island community. The cost of energy on Long Island is 51 percent above the national average, which poses a challenge to both residents and companies on the island. For example, graphene as a composite material may be used in windmills to create lightweight, strong turbines.

2013-3875 | INT/EXT | Newsroom