Technologies Available for License

Category: electronics & instrumentation

2023-010: Optical Phase Measuring Deflectometry for Precise Surface Metrology

Invention: 2023-010

Patent Status: Application Number US 2024/0426701 A1 was published on December 26, 2024

For technical and licensing related questions, email tcp@bnl.gov.

Summary

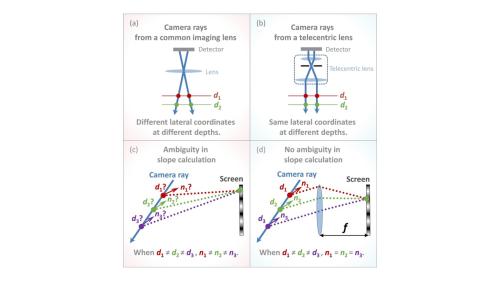

Figure: The CPMD configuration utilizes a telecentric imaging lens and a Fourier lens working together to realize the independence between the height reconstruction and the depth of sample positioning.

Freeform optical components are used in imaging systems is designed to improve the optical performance by eliminating the optical aberrations. As a high dynamic range and low-cost measurement solution, the Phase measuring deflectometry (PMD) technique has been applied to several scientific applications for deformation, curvature, and shape measurement. However, the traditional PMD is not suitable for the low-frequency form (freeform) measurement, largely due to the geometric calibration error and the sample positioning error. This deficiency in PMD strongly limits its use in many application scenarios, where an absolute surface shape measurement is required. For fabricating freeform optics, it is essential to get accurate in-process metrology feedback for the fabrication process. BNL researchers proposed a system and method that utilizes the principles of fringe phase measurement and deflectometry for accurate and reproducible measurements of flat and low-frequency specular surfaces. This new deflectometry system is named Collimated Phase Measuring Deflectometry (CPMD).

Description

The proposed CPMD device uses a telecentric camera lens in an on-axis optical geometry to restrict the camera rays parallel to each other and a set of collimation optics to collimate the beam from each source pixel on the screen. In contrast, traditional PMD measured slope results are sensitive to the depth of sample positioning, which leads to height-slope ambiguity problems. Any deviation from the depth can lead to significant low-frequency errors in the measured surface shape (Figure). With the CPMD setup, the measurement is insensitive to the depth of sample positioning, for example, the measured height dispersion is less than 30 nm RMS within a 10 mm depth range when measuring a 50-mm-diameter spherical mirror with a 200 mm radius of curvature.

Benefits

CPMD can highly reduce the requirement of the sample placement in practice, and therefore reduce the low-frequency error in the reconstruction result. It brings significant convenience in a practical measurement setup. For instance, it offers the possibility of automatic consequent metrology procedures, such as a sub-aperture stitching with the CPMD technique.

Applications and Industries

The CPMD technique enables the measurement of flat surfaces and low-frequency surface shape components and relaxing the axial depth tolerance of the sample positioning. These make CPMD more suitable for a wider range of applications, including optical fabrication with metrology for quality control, consumer products like cell phones and electronic watches curved screens, to industrial applications such as off-axis/free-form optical components, etc..

Journal Publication & Intellectual Property

Contacts

-

Poornima Upadhya

Manager Technology Transfer & Commercialization

Technology Commercialization

(631) 344-4711, pupadhya@bnl.gov

-

Avijit Sen

IP Licensing & Commercialization

Technology Commercialization

(631) 344-3752, asen@bnl.gov