Technologies Available for License

Category: electronics & instrumentation

2008-032: Nondestructive testing apparatus and method

Invention: 2008-032

Patent Status: U.S. Patent Number 83,682,892 was issued on February 5, 2013

For technical and licensing related questions, email tcp@bnl.gov.

Summary

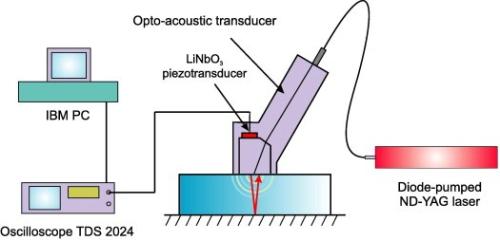

Figure: Experimental setup.

Inspecting materials for hidden damage or stress is important in many industries, such as aerospace, construction, and manufacturing. Traditional testing methods often require cutting into or damaging the object being tested, which can be costly and time-consuming. To avoid this, scientists and engineers use nondestructive testing (NDT) — a way to check for internal problems without harming the object. The invention described here builds on this approach, offering a precise and efficient way to detect such issues using a combination of laser technology and sensitive wave-measuring sensors.

Description

The nondestructive testing device and method described here use a laser to send energy into a solid object, creating tiny waves inside it. These waves can take different forms — some travel straight through the material, some move side to side, and others travel along the surface. The device also includes a sensor, known as a piezoelectric transducer, which detects and measures these wave movements. By analyzing the speed at which the waves travel, the system can identify hidden issues such as cracks, internal stress, or other defects. To determine if something is wrong, the measured wave speeds are compared to those in a similar object that is known to be free of defects. If the wave behavior is different, it may indicate a hidden problem inside the material.

Benefits

The use of laser-generated waves combined with piezoelectric sensors enables highly accurate detection of even small or deep-seated defects within solid materials. Because the method is nondestructive, it can identify internal issues without cutting, damaging, or altering the object being tested. This approach not only preserves the integrity of the material but also helps save time, reduce costs, and minimize waste.

Applications and Industries

This nondestructive testing technology has a wide range of practical applications across industries where material integrity and safety are critical. The relevant industry sectors include aerospace, automotive, construction, power generation, etc.

Journal Publication & Intellectual Property

Contacts

-

Poornima Upadhya

Manager Technology Transfer & Commercialization

Technology Commercialization

(631) 344-4711, pupadhya@bnl.gov

-

Avijit Sen

IP Licensing & Commercialization

Technology Commercialization

(631) 344-3752, asen@bnl.gov