Brookhaven National Laboratory's Quantum Material Press, or QPress, is a unique automated facility for the study of heterostructure materials. Made by stacking different two-dimensional materials, heterostructures have a host of exciting applications for quantum information science—an emerging field with the potential to revolutionize computation, communication, and sensing.

QPress is a first-of-its-kind experimental tool enabling automated synthesis of layered heterostructure materials useful to research in quantum information science (QIS). Funded by the U.S. Department of Energy (DOE) Office of Science, QPress is being constructed at the Center for Functional Nanomaterials—a DOE Office of Science User Facility at Brookhaven National Laboratory.

Ultrathin 2D materials

Two-dimensional (2D) materials are only a single atom thick. The most famous example is graphene, which is a sheet of carbon atoms that can be peeled off from the surface of graphite, a three-dimensional (3D) carbon material. Ultrathin and 2D materials can be layered into stacks to form new “heterostructure” materials with desirable properties. With QPress, researchers can layer any ultrathin material in any sequence, bypassing the usual constraints of chemical methods or epitaxial crystal growth.

Heterostructures & QIS

Ultrathin materials exhibit unique quantum properties because electronic states are confined to the atomic thickness. These quantum properties can be tuned based on the sequence and thickness of each layer in the heterostructure. Moreover, new states can be accessed by controlling the twist angle between layers. Ultrathin and heterostructure materials provide access to unique electronic states relevant to applications in quantum sensing, quantum computing, and quantum communication. For instance, one can study quantum Hall physics, anomalous superconductivity, topological valley transport, and single-photon emission.

QPress advantages

QPress is equipped with a set of experimental tools designed to automate the handling of delicate ultrathin materials. Traditional research into these materials has relied on manual, human-driven processes, with heterostructures fabricated using polymer adhesives to pick up 2D material “flakes,” which are carefully layered with micromanipulators. QPress provides mechanized and robotic systems to automate these tasks, making the entire workflow faster, easier, and more reproducible.

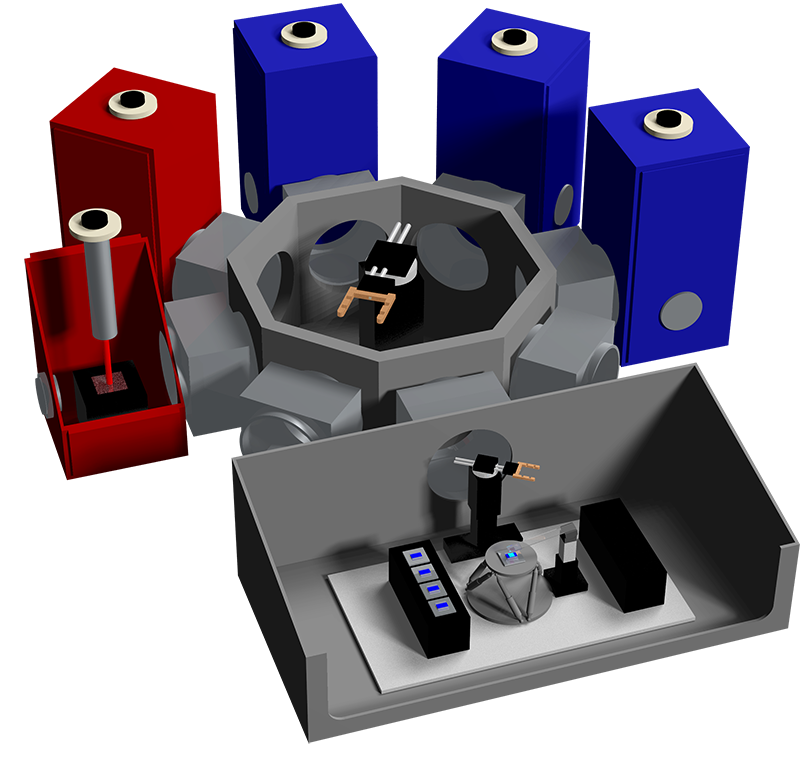

QPress is a modular system

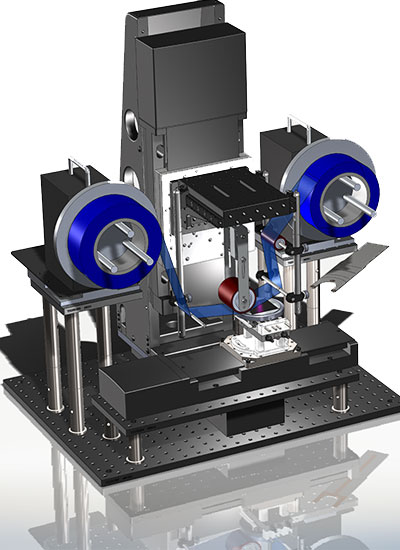

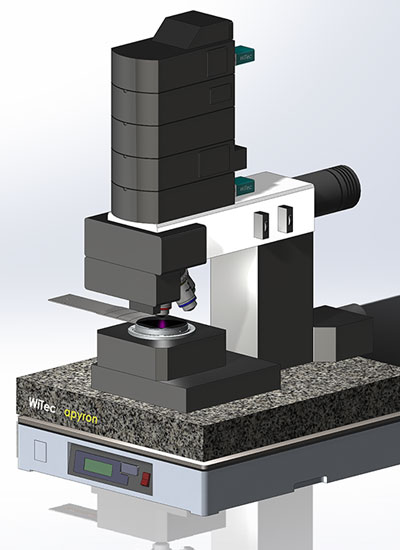

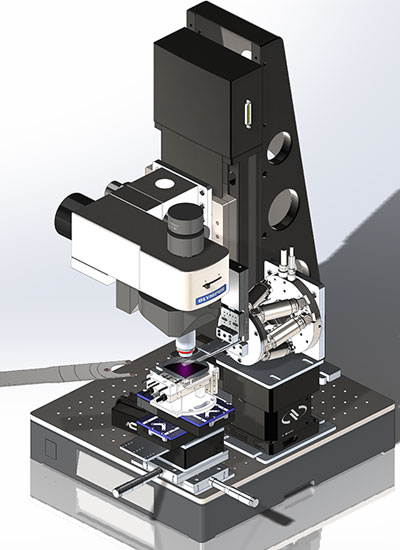

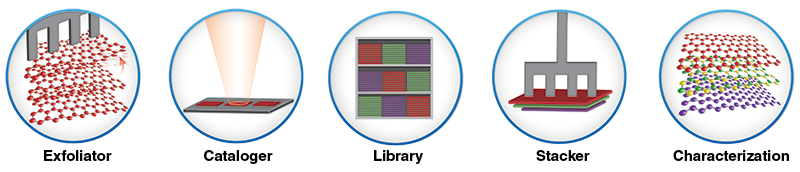

The QPress cluster tool robotically transfers substrates through an integrated sequence of synthesis, processing, and characterization stations. This tool features three custom-built modules: an exfoliator, cataloger, and stacker, each designed for robotic control and automation. This setup enhances the efficiency and reproducibility of synthesizing 2D heterostructures.

The cluster is equipped with:

- Sample Libraries: These allow for the storage and retrieval of substrates and intermediate samples under vacuum conditions.

- Deposition Methods: Includes an electron-beam system capable of handling various target materials.

- Pre-/post- Processing Methods: Features vacuum/argon annealing and oxygen plasma cleaning/etching.

- Characterization Methods: Comprises optical microscopy, Raman spectroscopy, photoluminescence spectroscopy (PL), and atomic force microscopy (AFM).

All components operate under vacuum or an inert atmosphere to facilitate the handling of air-sensitive materials, ensuring the integrity and quality of the materials throughout the process.

Funded by the U.S. Department of Energy (DOE) Office of Science, QPress is being constructed at the Center for Functional Nanomaterials—a DOE Office of Science User Facility at Brookhaven National Laboratory.