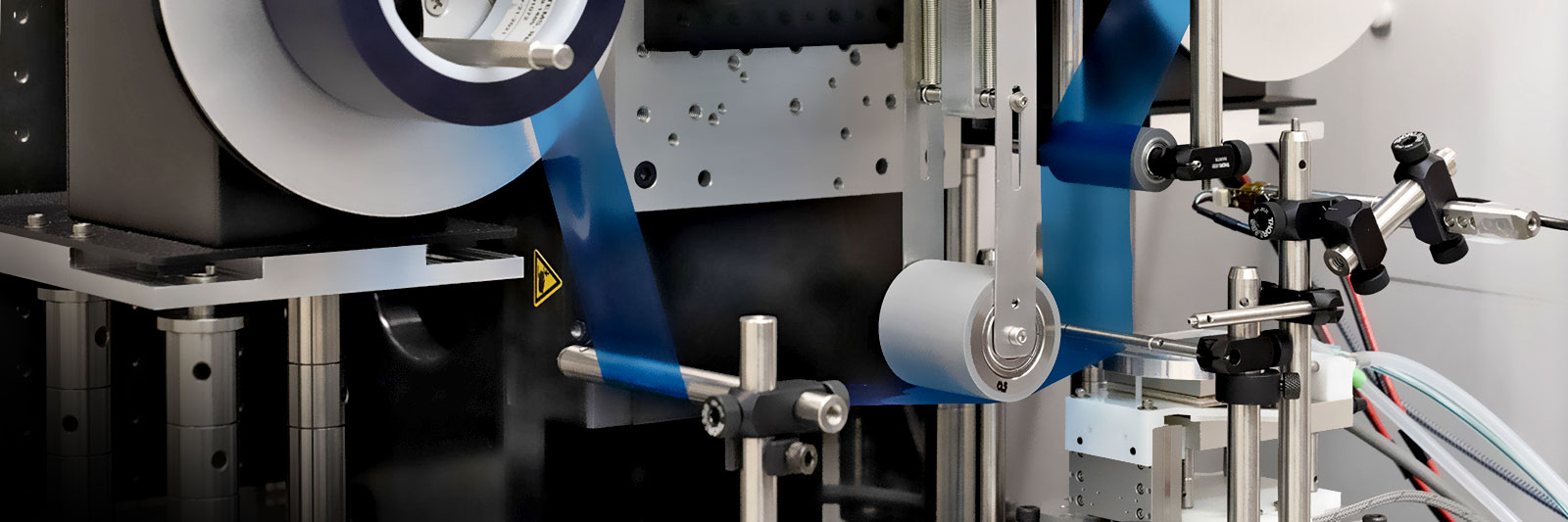

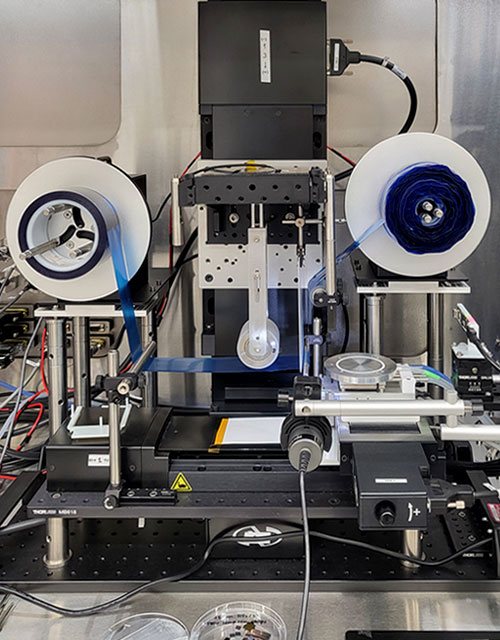

QPress Exfoliator

The exfoliator provides a mechanized version of the tape-assisted mechanical exfoliation steps.

Robotic tape exfoliation utilizes a fully mechanized exfoliation platform, or an Exfoliator, employing commercially available pressure-sensitive adhesive (PSA) tape, in a roller assembly can control the entire exfoliation process instead of human hands. This roller assembly can independently regulate various rolling and peeling conditions and allows us to study physical mechanisms in tape exfoliation.

Manual tape exfoliation involves repeatedly pressing and peeling tape on the target material, culminating with a final transfer onto a silicon dioxide (SiO2) wafer to achieve the desired thickness of mono or few-layered materials.

By mechanizing the flake generation step, the exfoliator speeds up the process of generating candidate flakes while enabling much more reproducible handling, which can be optimized for a given material.

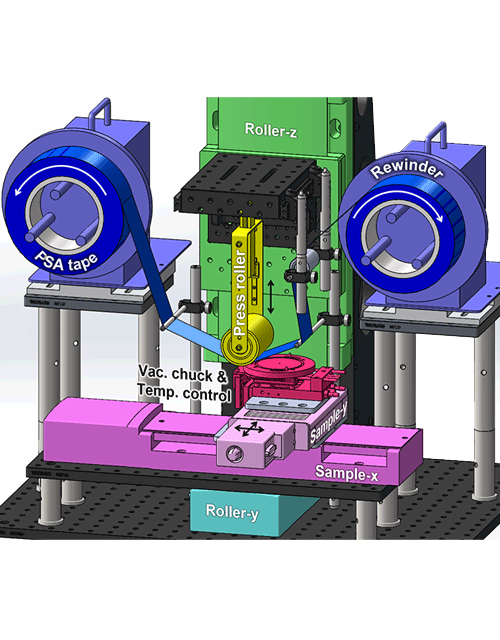

| Stage | Component | Description/Control |

|---|---|---|

| Tape Stage | Blue dicing tape | High cohesion: less residues |

| Tape rewinders | Tape position & Peeling force control | |

| Sample Stage | Sample X-stage | Rolling/peeling speed (vr, vp) control |

| Sample Y-stage | Tape/sustrate alignment | |

| Thermal vacuum chuck | Temperature control ( room < T < 200 deg C) | |

| Lifting pins | Robot loading/unloading substrates | |

| Compression stage | Press spring roller & Z-stage | Pressure (P) control, P < 0.55 MPa (*Manual ~0.25 MPa) |

| Roller Y-stage | Roller/tape alignment | |

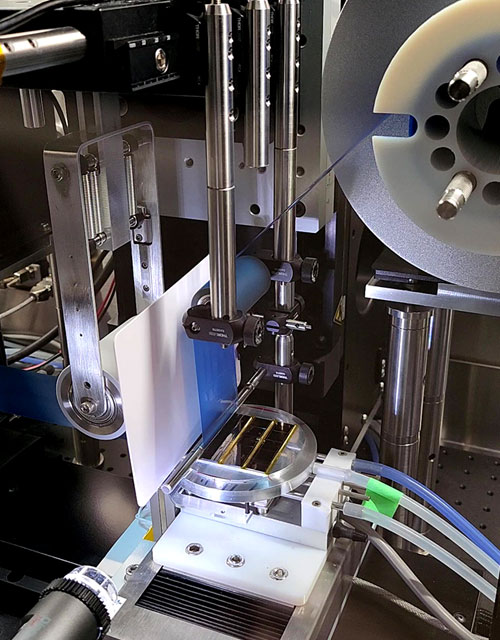

| Peeling-off stage | Peeling angle roller | Assisting peeling angle control |

| Motorized rewinders | Peeling force (F/b) control |

Status: The exfoliator is fully operational in Argon glovebox and currently accepting user proposals. We have developed and optimized exfoliation recipes for high-demand materials such as graphene, hBN, and transition metal dichalcogenides (TMDs). The system and its recipes are undergoing continuous refinement to enhance performance and user experience.

Exfoliator in glovebox

Exfoliator schematic

Exfoliator peeling off