QPress Stacker

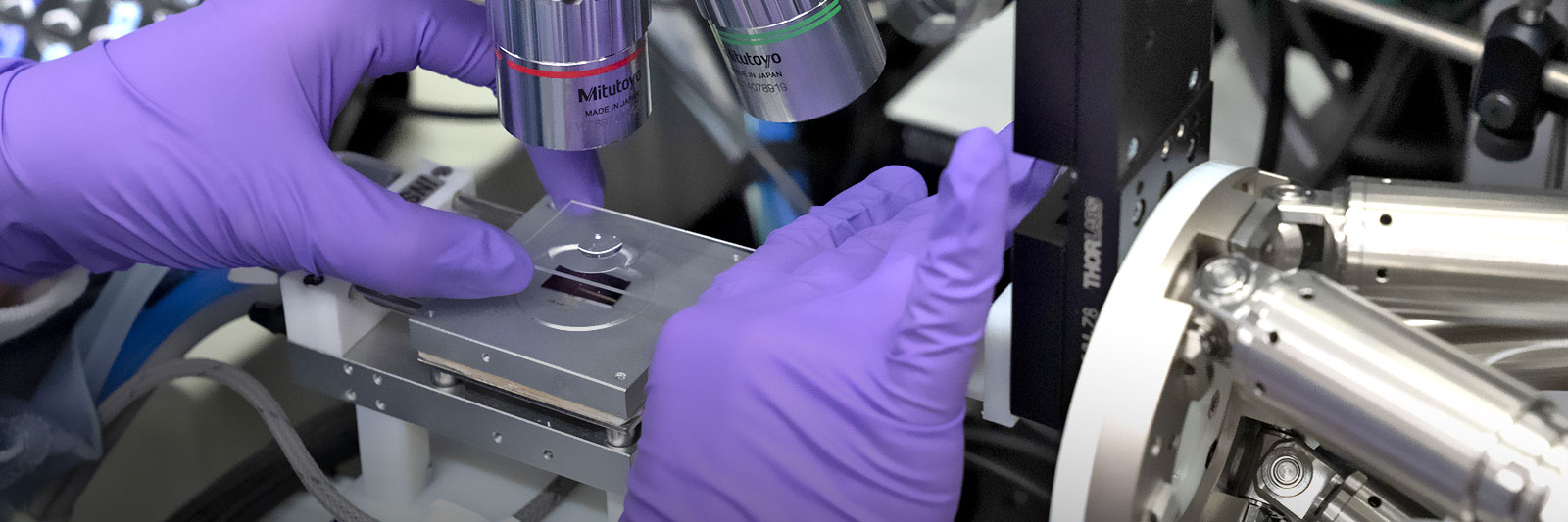

The stacker is a sophisticated robotic dry-transfer system engineered for the precise handling and placement of exfoliated flakes using a polymer adhesive stamp.

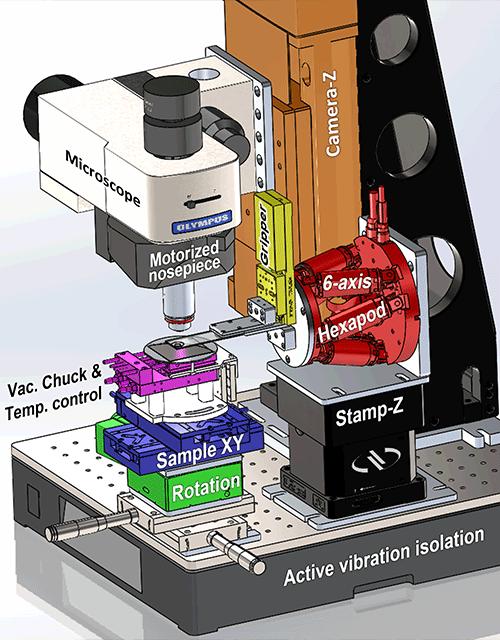

A hexapod provides six degrees of freedom (x, y, z, pitch, yaw, and roll), enabling complex and precise control of the stamp during the approach, pressing, and detachment phases of the stacking process. The substrate motion stage is capable of navigating to selected flakes of interest and rotating them—an essential feature for fabricating layered moiré heterostructures. The system also includes integrated heaters, allowing temperatures up to 300 °C for the substrate and 200 °C for the stamp, enabling precise thermal control during the transfer process and supporting mild annealing.

Status: The stacker is fully operational in Argon glovebox and currently accepting user proposals. This system is completely motorized and can be remotely controlled by an operator located outside of the glovebox, ensuring safety and precision in handling.

| Stage | Component | Description/Control |

|---|---|---|

| Substrate stage | XY-stages | res. 20 nm |

| Rotation stage | ±155°, res. = 0.2 mdeg | |

| Temperature control | room < T < 300 °C | |

| Lifting-pins | Robot loading/unloading substrates | |

| Stamp stage | 6-axis stamp control | res. x = 0.08 um y, z = 0.2 um pitch = 0.28 mdeg yaw, roll = 0.14 mdeg |

| z-stage | res. 0.10 µm | |

| Stamp gripper | Holding stamp | |

| Temperature control | room < T < 200 °C | |

| Microscope stage | Camera | 18MP color CMOS |

| Camera focus (z) | Motorized stage | |

| Motorized nosepiece and objected lenses |

Super-long Working distance lenses x5, x20, and x50 |

Status: The stacker is fully operational in Argon glovebox and currently accepting user proposals. This system is completely motorized and can be remotely controlled by an operator located outside of the glovebox, ensuring safety and precision in handling.

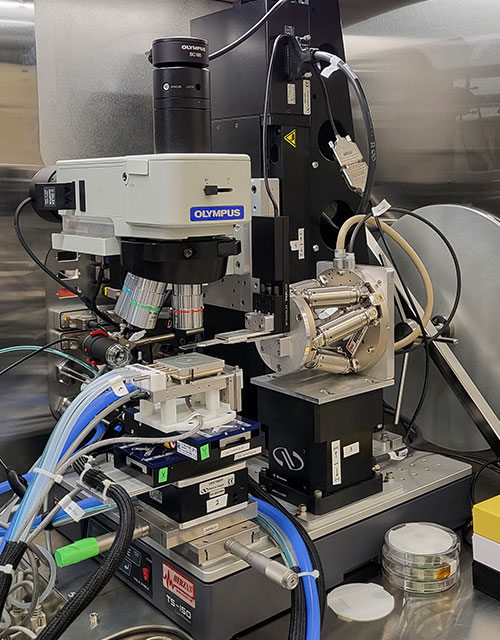

Stacker in glovebox

Stacker components

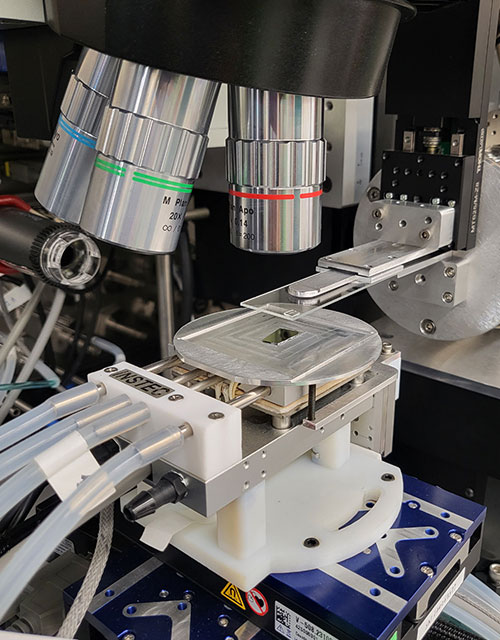

Closeup of Stacker microscope stage