Coatings Choose All Sides for a Biomedical Imaging Win

March 31, 2021

enlarge

enlarge

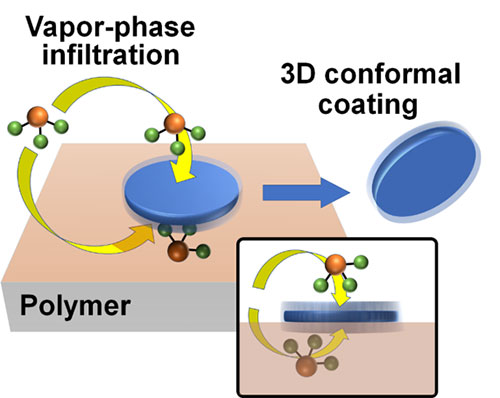

A schematic 3D conformal coating layer of a microdisc laser. Vapor-phase precursor molecules can reach the unexposed bottom surface of the laser by diffusing through the polymer substrate, resulting in an all-around coating.

What is the scientific achievement?

Harvard Medical School users and CFN staff developed a new method for coating three-dimensional (3D) laser microdiscs and other nanoparticles with ultrathin metal oxides. Placed on a polymer substrate, the material can be coated on all sides by vapor-phase infiltration synthesis because precursor molecules can diffuse freely through the polymer. The team used this approach to coat laser microdiscs with a 10 nm thick passivating alumina film, allowing the microdiscs to be used in optical cellular imaging in vivo and in vitro.

Why does this achievement matter?

Traditional encapsulation of 3D particles by vapor coating requires large quantities of bulk powders and physical tumbling, making the technique difficult to apply to small amounts of micro- and nanoparticles. The new approach is uniquely applicable to coating even a single nanoparticle.

What are the details?

Conformal ultrathin inorganic coating of micro- or nanoparticles generally requires specialized atomic layer deposition systems that can levitate particles using mechanical tumbling or a fluidized bed while requiring a large quantity of bulk powder with minimum working quantities at least 10s–100s mg. We have developed a new 3D conformal coating method for a small quantity of stationary particles, based on vapor-phase infiltration. The method leverages the diffusion of vapor-phase precursors through an underlying inert polymer film to achieve growth of an ultrathin metal oxide coating on all sides of the particle simultaneously, even on the side in contact with the substrate. The method was successfully applied to achieve 3D conformal coating of 10 nm thick alumina on less than 10 ng of individual laser microdiscs used in in vivo and in vitro optical cellular imaging and hybrid perovskite nanoparticles used in optoelectronics. The encapsulated laser microdisc displayed an excellent stability under a hydrogel and cell environment, with less than a 1 nm spectral shift in its emission wavelength after emitting 1.6 billion laser pulses. The developed method represents a unique conformal coating strategy tailored for a small quantity of micro- and nanoparticles, in principle applicable down to a single micro/nanoparticle.

CFN Capabilities

CFN Materials Synthesis and Characterization and Electron Microscopy Facilities were used for this study.

Publication Reference

A.C. Liapis, A. Subramanian, S. Cho, K. Kisslinger, C.-Y. Nam, and S.-H. Yun, Conformal Coating of Freestanding Particles by Vapor-Phase Infiltration, Adv. Mater. Interfaces 7, 24 (2020).

DOI: 10.1002/admi.202001323

OSTI: https://www.osti.gov/biblio/1708929-conformal-coating-freestanding-particles-vaporphase-infiltration

Acknowledgement of Support

This work was supported by the U.S. National Institutes of Health (NIH) grants DP1-OD022296, P41-EB015903, and R01-CA192878 and National Science Foundation (NSF) grant ECCS-1505569. This research used resources of the Center for Functional Nanomaterials, which is a U.S. DOE Office of Science Facility, at Brookhaven National Laboratory under Contract No. DE-SC0012704.

2021-18849 | INT/EXT | Newsroom