System Development

Mechanical Engineering, Fabrication, and Integration

The Instrumentation Department’s Mechanical Engineering, Fabrication, and Integration Group transforms conceptual designs into functional components and complete systems. With in-house expertise and fabrication capabilities—including a fully equipped machine shop—we support large collaborative experiments, prototype development efforts, and commercial applications. Our designs, components, and systems are used in a range of technologies, from ultrahigh vacuums capable of producing photocathodes for electron sources to parts for telescopes and neutrino detectors.

Our Capabilities

- Generation of innovative, creative mechanical design and fabrication solutions for application-specific needs, such as for cryogenics and ultrahigh-vacuum and extreme-high-vacuum systems that require substrate transfer, substrate heating, and evaporative deposition sources

- Development of assembly and test fixtures for concept realization and validation

- Verification of completed design elements on computer-aided design (CAD) and computer-aided manufacturing (CAM) software

- Validation of design requirements via computer-animated simulations and analyses run on Ansys software

- Inspection of fabricated parts to ensure conformity to specifications

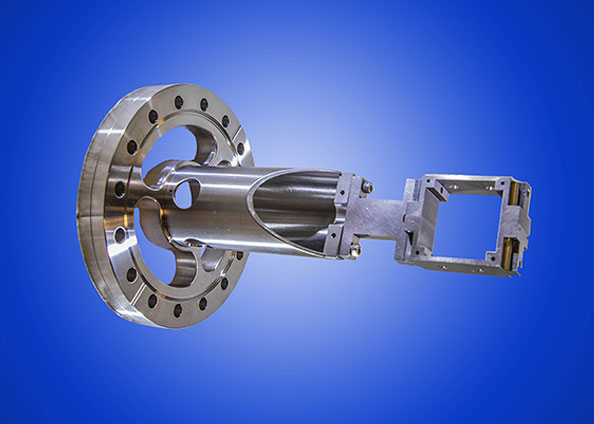

A titanium magazine for cathode storage.

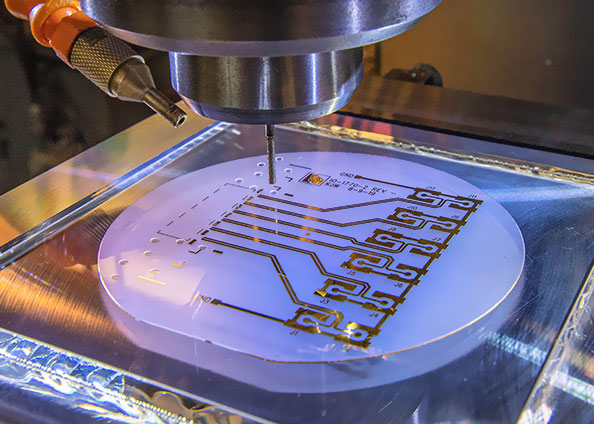

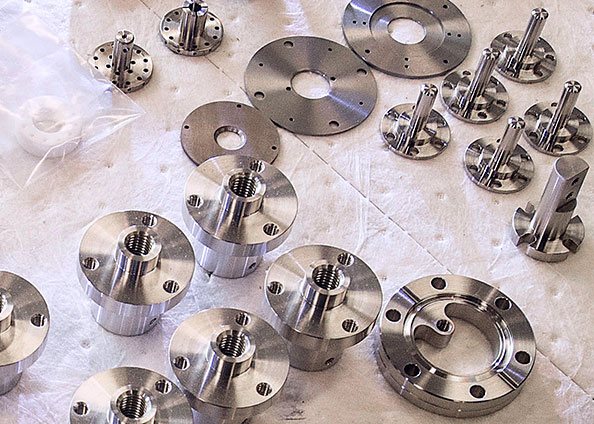

Various components for cathode deposition system development.

A cathode heater assembly.

Case Studies

Radio telescope calibration

Launching a fixed-wing unmanned aerial vehicle.

Radio astronomy experiments focusing on the 21 cm wavelength emitted by hydrogen seek to map the density of the universe at the largest scales. Radio telescope calibration is critical to the detection of this hydrogen emission line at cosmic distances. To perform this calibration, we are designing and deploying long-endurance fixed-wing unmanned aerial vehicles. These airplane-like drones present unique system integration and operational challenges, which we are solving using novel 3-D printing techniques and aerodynamic antenna designs.

Astronomical imaging

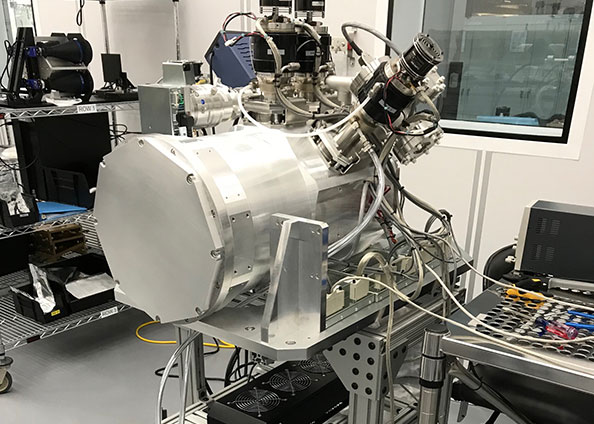

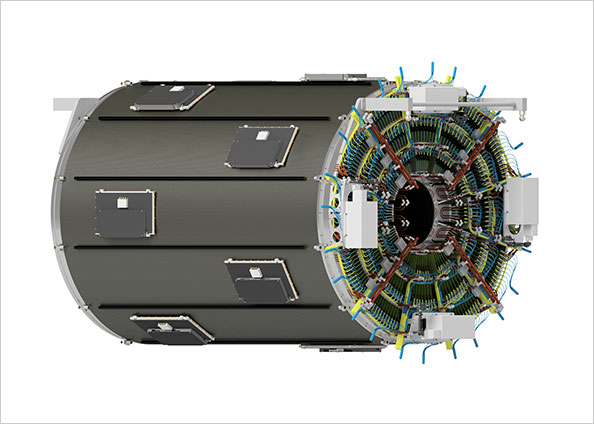

Rubin Observatory comissioning camera.

We designed novel optical systems to emulate the imaging behavior of the Rubin Observatory’s Simonyi Survey Telescope, including under the atmosphere’s dynamic aberrating effects. Following this lab-based performance validation, we designed the core of the telescope's commissioning camera with multizone active cooling, custom electrical vacuum feedthroughs, and specialized mechanical isolation to protect the 144-megapixel sensor array from the rigorous vibration of multiple cryocoolers. We also developed brushless motors and controllers for in-vacuum manipulation of isotope sources to test the charge-transfer efficiency of the telescope's sensors. These efforts will help prepare the telescope for its 10-year astronomical survey to collect data on the universe’s structure and evolution.

Particle detection

Rendering of the interior of sPHENIX detector.

The sPHENIX experiment planned at Brookhaven’s Relativistic Heavy Ion Collider will further our understanding of how interactions between the smallest building blocks of matter give rise to the remarkable properties of the quark-gluon plasma, a four-trillion-degree “soup” of fundamental particles that filled the early universe. In collaboration with sPHENIX team members, we are providing the conceptual designs, models, technical drawings, physical phenomena simulations, and assembly procedures for the compact Time Projection Chamber and Intermediate Silicon Strip Tracker. Working within several engineering constraints, we are spearheading the assembly, installation, and integration of these two detectors, which are part of the sPHENIX high-precision tracking system.