Tuning Electrochemical & Electronic Properties

Scientists present a new approach for scalable fabrication of nanocomposites for novel memory or processor devices

March 31, 2022

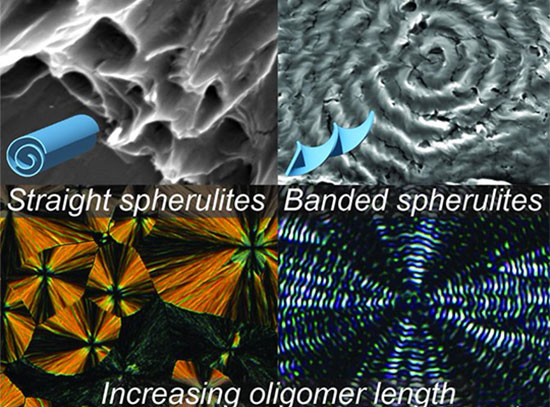

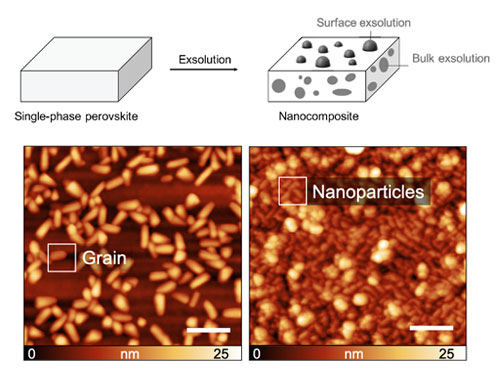

The lower panel shows how the material changes after the exsolution process depicted in the upper image. Image credit: Adv. Funct. Mater. 32, 2108005 (2022)

The Science

Scientists demonstrated that exsolution, a fabrication process, can be used to create metal oxide nanocomposites with tunable chemical, magnetic, and electrical properties.

The Impact

This study presents a new approach for scalable fabrication of nanocomposites with special electrochemical and electronic features desired in novel memory or processor devices or clean energy technologies.

Summary

Many everyday technologies, such as novel computer memory chips, processors, or clean energy devices are getting smaller to fit our needs, entering the realm of nanotechnology. However, just scaling down the manufacturing procedure doesn’t create devices with the desired chemical, magnetic, or electric properties. Instead, researchers need to develop new manufacturing processes to meet our needs.

In this study, a team of scientists demonstrated that exsolution, a fabrication process, can be used to create metal oxide nanocomposites with tunable chemical, magnetic, and electrical properties. The team used a thin-film material, La0.6Sr0.4FeO3 (LSF), as a model system to explore how changes in the exsolution process would influence the properties of the material. They found that the exsolution changed the conductive properties of the LSF by two orders of magnitude. Before exsolution the material displayed mainly ionic conductivity, while after the exsolution process the material was dominated by electronic conductivity. The team showed through numerical analysis that this change arises from iron deficient channels created by the exsolution. Similarly, they discovered how to tune the magnetic properties through temperature changes during the exsolution process.

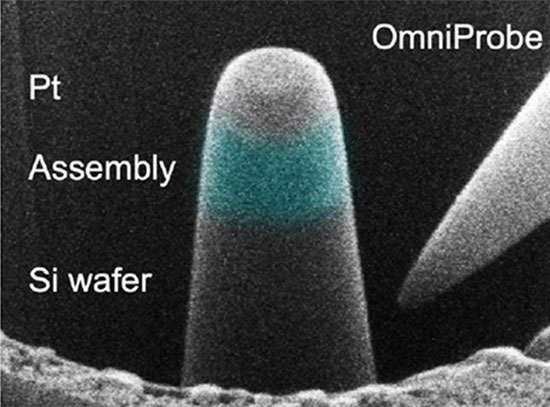

The researchers studied this process by collaborating with the scientists of the In situ and Operando Soft X-ray Spectroscopy (IOS) beamline at the National Synchrotron Light Source II (NSLS-II). They used the in situ ambient pressure x-ray photoelectron spectroscopy (APXPS) capabilities of the beamline to understand how the process affected the material’s properties. Additionally, the team performed ex situ measurements at the Advanced Light Source (ALS). Both the NSLS-II and ALS are U.S. Department of Energy (DOE) Office of Science user facilities located at DOE’s Brookhaven National Laboratory and Lawrence Berkeley National Laboratory, respectively.

The overall findings of this work show the potential of bulk exsolution in synthesizing tunable multifunctional nanocomposites, which can benefit a broad range of applications including nanophotonics, thermoelectric devices, multiferroics, and memory/logic technologies.

Download the research summary slide (PDF)

Contact

Bilge Yildiz

Massachusetts Institute of Technology

byildiz@mit.edu

Publications

Jiayue Wang, Komal Syed, Shuai Ning, Iradwikanari Waluyo, Adrian Hunt, Ethan J. Crumlin, Alexander K. Opitz, Caroline A. Ross, William J. Bowman, Bilge Yildiz. Exsolution Synthesis of Nanocomposite Perovskites with Tunable Electrical and Magnetic Properties. Adv. Funct. Mater. 32, 2108005 (2022) DOI: 10.1002/adfm.202108005

Funding

The authors would like to thank the Exelon Corporation and the MIT Energy Initiative Seed Fund Program for supporting the work presented in this paper. This research used the synchrotron radiation facilities at the National Synchrotron Light Source II (IOS/23-ID-2 beamline), a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Brookhaven National Laboratory under Contract No. DE-SC0012704; and the Advanced Light Source which was supported by the DOE Office of Basic Energy Sciences under Contract No. DE-AC02-05CH11231. For STEM-EDS characterization work, the authors acknowledge the use of facilities and instrumentation at the UC Irvine Materials Research Institute (IMRI), which is supported in part by the National Science Foundation through the UC Irvine Materials Research Science and Engineering Center (DMR-2011967). J.W. thanks Dimitrios Fraggedakis (MIT) for the helpful discussions on the Hashin–Shtrikman bounds. J.W. thanks Andreas Nenning (TU Wien) for the assistance on the Van der Pauw measurements. W.J.B. acknowledges UCI new faculty start-up funding. K.S. acknowledges support from US Department of Education Graduate Assistance in Areas of National Need (GAANN) Fellowship. C.R. and S.N. acknowledge support from NSF DMR 1419807.

2022-20659 | INT/EXT | Newsroom