Soft Substrates Create Surprisingly Stable Glass

June 14, 2024

enlarge

enlarge

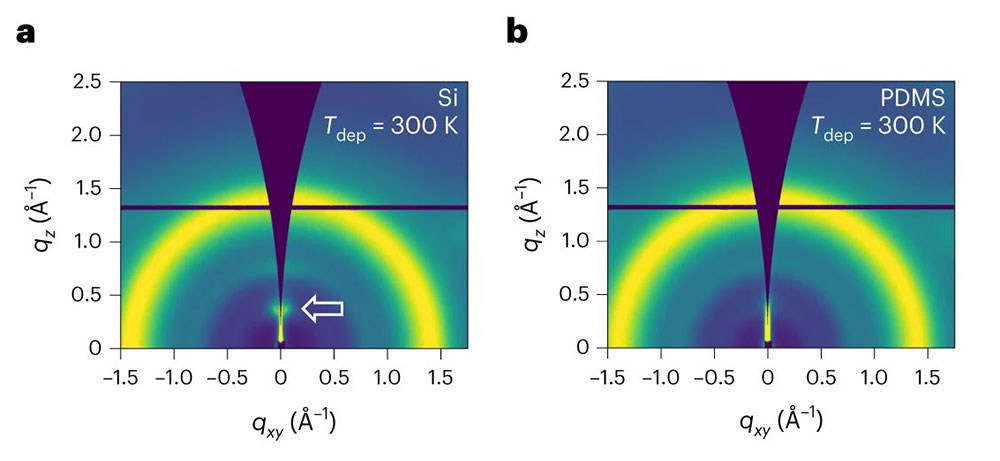

Two-dimensional grazing incidence wide-angle X-ray scattering patterns for films deposited on silicon (a) and polydimethylsiloxane (b). The arrow denotes an additional scattering feature corresponding to molecular layering. Credit: Nat. Mater. (2024)

The Science

Researchers engineer a more rigid, dense glass thin film using vapor deposition on a soft, rubbery substrate.

The Impact

This technique expedites the slow aging process needed to make glass more stable and durable, which could benefit glass’s wide range of scientific and industrial applications.

Summary

Scientists have been experimenting with a coating technique called physical vapor deposition (PVD) to create stable glass thin films. If glass molecules are deposited on a substrate at a specific temperature, layers with a uniform arrangement of molecules are created. Liquid quenched glass found in nature is aged for millions of years before achieving that kind of stability. Despite PVD being much quicker than nature, the process can still take a prohibitively long time to create stable glass films.

Typically, PVD is performed on rigid surfaces, but Researchers from the University of Pennsylvania, State University of New York Cortland, and the National Synchrotron Light Source II (NSLS-II), a U.S. Department of Energy (DOE) Office of Science User Facility at DOE’s Brookhaven National Laboratory, investigated the impact of using soft, rubbery substrates instead. The scientists found that this change significantly accelerates the process of achieving stable glasses. Gaining similar properties on rigid substrates would require 10 million times slower deposition, taking ~3,000 years. These glasses also exhibit higher density and greater stability compared to those deposited on rigid surfaces. In fact, the rate of equilibration on soft substrates is enhanced by several orders of magnitude, allowing for the creation of glasses with properties comparable to those achieved through much slower processes on rigid substrates.

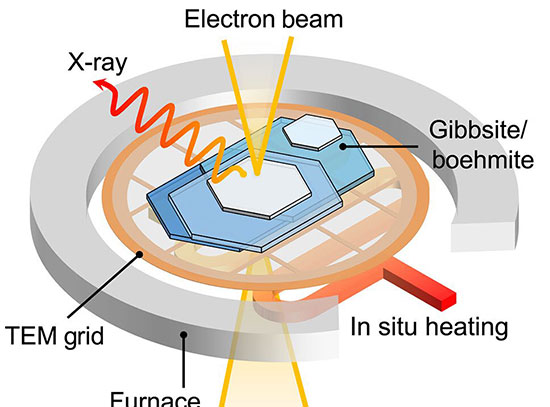

To help characterize these high-density stable glass thin films, scientists used the Soft Matter Interfaces (SMI) beamline at NSLS-II. They analyzed the structure with one of the beamline’s flagship techniques — grazing incidence wide-angle X-ray scattering. A beamline-developed analysis package then facilitated the quantification of the molecular orientation of the deposited glasses. This finding could have significant implications for various industries, including electronics and packaging, where stable glass materials are crucial.

Download the research summary slide (PDF)

Contact

Zahra Fakhraai

University of Pennsylvania

fakhraai@sas.upenn.edu

Publications

Luo, P., Wolf, S., Govind, S., Stephens, R., Kim, D., Chen, C., Nguyen, T., Wasik, P., Zhernenkov, M., Mcclimon, B., and Fakhraai, Z. High-density stable glasses formed on soft substrates. Nat. Mater. (2024). DOI: https://doi.org/10.1038/s41563-024-01828-w

Funding

We thank M. D. Ediger for insightful discussions. We acknowledge financial support from the National Science Foundation (NSF) Materials Research Science and Engineering Centers (MRSEC) under grant DMR-1720530. Support during manuscript revisions and final editing was provided by Wisconsin MRSEC grant DMR-2309000. We acknowledge the use of the Dual Source and Environmental X-ray Scattering facility operated by the Laboratory for Research on the Structure of Matter at the University of Pennsylvania supported by NSF through DMR-2309043. This research used the 12-ID (SMI) beamline of the National Synchrotron Light Source II, a US Department of Energy (DOE) Office of Science User Facility, operated for the DOE Office of Science by Brookhaven National Laboratory under contract no. DE-SC0012704. P.L. acknowledges postdoctoral fellowship funding from the School of Arts and Sciences of the University of Pennsylvania. C.Y.C. acknowledges support from the NSF Graduate Research Fellowship Program (NSF GRFP, DGE-1845298).

2024-21948 | INT/EXT | Newsroom