Advancing in situ Transmission Electron Microscopy Research with Meng Li

interview with a CFN Staff Scientist

September 23, 2024

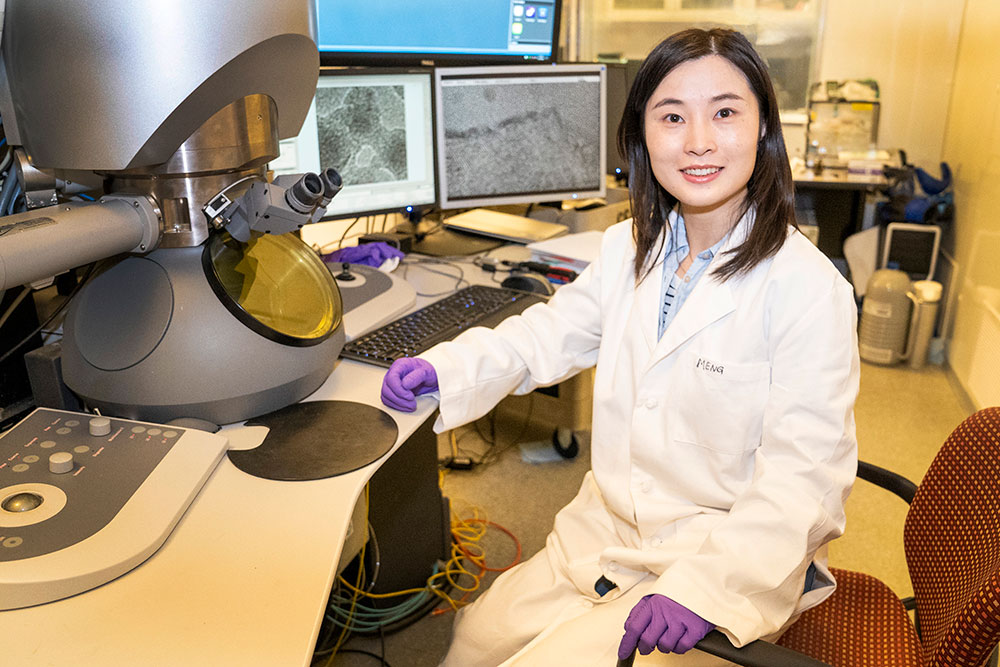

Materials scientist Meng Li is a staff scientist in the Electron Microscopy group at the Center for Functional Nanomaterials (CFN), a U.S. Department of Energy (DOE) Office of Science user facility at DOE’s Brookhaven National Laboratory, which she joined last year. Li splits her time between helping users conduct in situ experiments at CFN’s cutting-edge transmission electron microscopes (TEMs) and conducting her own research. Her research interests include in situ TEM studies of corrosion and catalysis and developing new in situ microscopy instrumentation and experimental tools.

Describe your role at CFN.

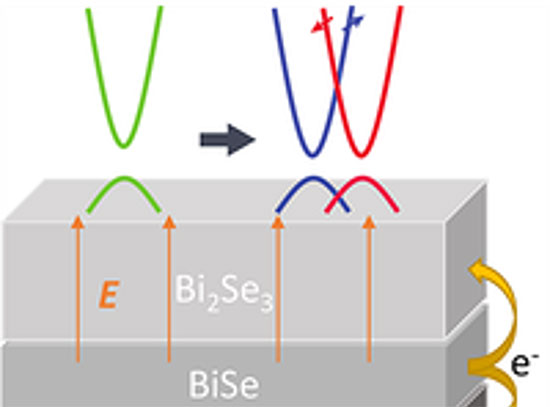

My role at CFN mainly focuses on “in situ” and “operando” transmission electron microscopy, which means that in addition to characterizing the structure of materials at static, ideal states, such as in a vacuum at room temperature, we can also apply external stimuli — such as gas and heat — to the sample inside the TEM. This approach allows us to capture the atomic-scale dynamic changes of the sample in real time, and we measure the properties or reaction products to get a direct correlation between the structure and properties of the material. For example, for a catalyst sample, instead of imaging what it looks like before and after the reaction and guessing what happened, we are trying to see how the catalyst structure evolves during the reaction process — and link the structures with its catalytic properties, which are critical for understanding these materials.

How are you developing ways to improve these studies?

These advanced experiments require specialized sample holders and/or microscopes. At CFN, we have a unique Titan Environmental TEM (E-TEM) and an upcoming state-of-the-art Nion environmental scanning TEM that enable us to introduce gases into the microscope, and we also have a suite of in situ TEM sample holders that enable heating, cooling, gas flow, liquid environments, electrical biasing, and mechanical testing. These in situ TEM experiments generate large quantities of data, especially movies or time-sequence images, which are extremely time-consuming and challenging to process with conventional TEM data analysis tools designed for single images.

Hence, I focus on developing hardware and software for CFN’s TEMs that can lead to a better understanding of atomic-scale mechanisms, especially catalytic reactions and corrosion. I have a particular interest in coming up with ways to advance in situ environmental TEM studies. One of these approaches is developing sample holders that incorporate special micro-electro-mechanical systems (MEMS) — tiny silicon-based devices that combine mechanical and electrical components. These holders allow us to study samples in a variety of ways. Another approach is developing software tools, including artificial intelligence and machine learning methods, to accelerate and enhance the analysis of in situ TEM data and to get deeper insights into the experimental results.

What kind of support do you offer user scientists?

Essentially, I help users run their in situ TEM experiments so that they leave CFN with the data they came to gather. At our E-TEM, we are able to subject samples to different environments, such as various gaseous environments, and “watch” the atomic-level reaction in real time. But getting good, meaningful data requires a lot of trial and error and experience. My role is to help users throughout the process so they can increase their success rate in the experiment and get useful data. I also provide them the support they need for advanced data analysis.

How does your work with users complement your own research?

During my own research on corrosion and catalysts, I gained a lot of experiences and developed tools to make these types of experiments and research more efficient, and these experiences are widely applicable to the users. I can bring my designs to user experiments and better understand what is working well or what should be changed. For example, I have developed new sample holders for microscopy experiments, and being able to deploy them in user experiments gives me valuable feedback. It also contributes to CFN’s unique capabilities.

I am also involved in the software side of things, developing codes to better analyze the data. The kind of data my users get are mainly in the form of images and movies, and we need to pull quantitative information from this raw data. I do my best to help accelerate and automate this process. Being able to deploy my software tools during user experiments is very helpful, and I really like this part of my job.

What kinds of activities do you enjoy outside of work?

Learning new things and trying new activities is a way for me to relax when I’m not working. I have lots of hobbies — so many that I have to take turns doing them because I don’t have enough time! I like painting, and I also like playing musical instruments. I’m learning piano, and I play a classic Chinese string instrument. I also have two cats, and they do keep me busy and entertained every day.

Brookhaven National Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit science.energy.gov.

Follow @BrookhavenLab on social media. Find us on Instagram, LinkedIn, X, and Facebook.

2024-22097 | INT/EXT | Newsroom