Integrated Electronics

Printed Circuit Boards

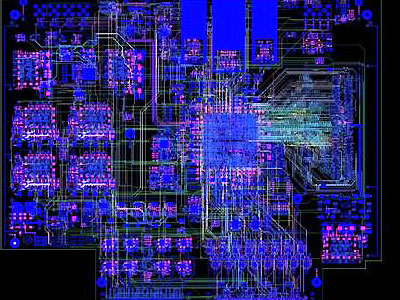

The Instrumentation Department’s Computer-Aided Design (CAD) and Printed Circuit Board (PCB) Design Group assists scientists and engineers in the design of complex multilayer PCBs, including those that serve as detector elements. Through these collaborations, we move preliminary designs to mature production-ready packages for manufacturing. Our PCBs are used in a range of technologies, from medical imagers and x-ray synchrotron beam position monitors to particle detector readouts and backend electronics.

Our Capabilities

- Progression of analog or digital designs from conception through fabrication of a finished product

- Delivery of innovative and creative technical solutions customized for particular application needs

- Establishment of tailored design standards and configurations based on challenging and unique scientific goals

- Collaboration with fabrication facilities to develop the best designs for manufacturing

- Design of advanced and low-noise signal processing systems

- Verification of completed design elements on CAD and computer-aided manufacturing (CAM) software

- Inspection and optimization of previously created designs for fabrication and assembly by PCB manufacturers

Case Studies

Gamma-Ray Detection

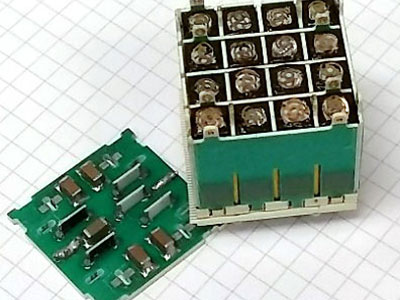

A CZT module prototype filled with 16 detectors, each 6 × 6 × 20 mm3. The CZT bars are packed inside an interlocked printed-circuit-board structure.

Gamma-ray spectroscopy for nuclear security and nonproliferation, astrophysics, and medical imaging relies on highly sensitive detectors with a high signal-to-noise ratio. We designed an extremely low-noise analog/digital application-specific integrated circuit (ASIC) carrier board, detector board, and high-voltage board for virtual Frisch-grid CZT gamma-ray detectors. The detector board carries a 4×4 array of CZT sensors, which we connected to the ASIC carrier board through a connector board customized to work within certain size constraints and our PCB pad layout. Our boards have been implemented in detectors in use by the U.S. Department of Energy, U.S. Department of Homeland Security, Defense Threat Reduction Agency, and International Atomic Energy Agency.

Neutron Detection

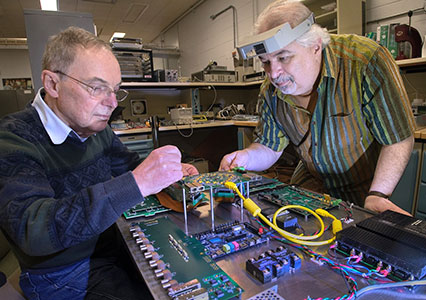

A flange transition board (elevated) connected to a series of other boards—pad detector boards, readout cards, and rigid-flex cables—that we designed in house for the scattered neutron detector at ANSTO.

The detection of scattered neutrons typically requires gas gain (multiplication of electrons in the gas) to amplify readout signals. We overcame this requirement by building a low-noise detector board, readout card, and timing and control board system. Our system was installed in the ionization-mode thermal neutron detector of the small-angle neutron scattering beamline Quokka at the Australian Nuclear Science and Technology Organization (ANSTO). This system has enabled unprecedented detector operation rates (up to 106 neutrons/sec) for dynamic food science studies and more efficient beamtime use.

Cold Electronics Readout

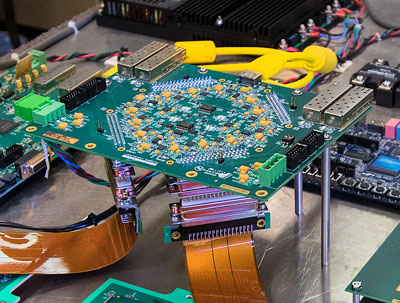

The layout of the DUNE WIB had to satisfy multiple routing requirements—such as short routes to the memory connectors and correct spacing between routes for optimal timing and signal integrity—because of its double data rate 4 (DDR4) synchronous dynamic random-access memory (SDRAM). The latest generation of memory in computing, DDR4 SDRAM supports increased memory transfer rates and lower power consumption.

The electronics for the Deep Underground Neutrino Experiment (DUNE) liquid-argon-filled massive detectors must be able to operate at ultracold temperatures to measure oscillations of fundamental particles called neutrinos. For the detector prototyping phase, we designed a cold electronics readout chain and frontend motherboard with a mezzanine card containing 128 channels of low-noise electronics and four 1.28 Gbps high-speed links. Power and signals pass through a gas-tight flange PCB into a warm-interface board (WIB), both components we developed.

X- and Gamma-ray Astronomy

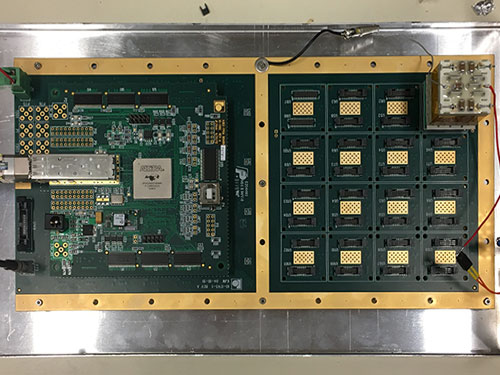

Testing of the prototype gamma CZT detector array for NASA. The motherboard shown has just one CZT “crate” inserted for testing. Each crate contains 16 CZT detectors, and each CZT detector delivers five signal channels.

Balloon flights launched by the National Aeronautics and Space Administration (NASA) need high-sensitivity, low-noise detectors to observe high-energy x-rays and gamma rays from objects in space. We designed an analog/digital CZT calorimeter motherboard carrying an array of 16 position-sensitive, low-noise 4 × 4 virtual Frisch-grid CZT detectors to support these NASA missions.