Turning Up the Heat to Create New Nanostructured Metals

Scientists used heat to drive a spontaneous process in which different metals mixed to form 3-D interlocking nanostructures in thin films, with applications for catalysts, solar cells, and biomedical sensors

January 31, 2020

enlarge

enlarge

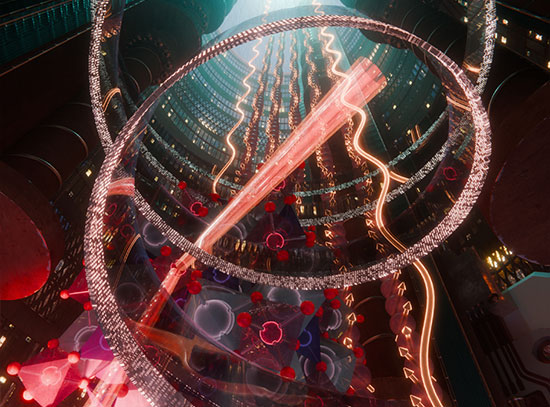

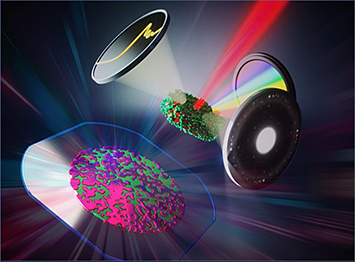

Artist's impression of multimodal characterization of a bi-continuous thin film using a combination of x-ray and electron analysis methods. Image credit: Mater. Horiz., 6, 1991-2002 (2019)

The Science

Scientists demonstrated that solid-state interfacial dealloying (SSID) can be used to create bi-continuous nanostructured thin films for potential applications in catalysis, biomedical sensing, and energy storage.

The Impact

Ranging from household mirrors to coatings on cars and electronics, thin films play an important role in our daily lives, and advances in their creation process have enabled a wide range of technological breakthroughs. This work advances the mechanistic understanding of the SSID process and sets a path for designing future nanostructured metallic thin film materials for applications.

Summary

In this study, scientists developed a new approach for making metal-metal composites and porous metals with a 3-D interconnected “bi-continuous” structure in thin films at size scales ranging from tens of nanometers to microns. Metallic materials with this sponge-like morphology—characterized by two coexisting phases that form interpenetrating networks continuing over space—could be useful in catalysis, energy generation and storage, and biomedical sensing.

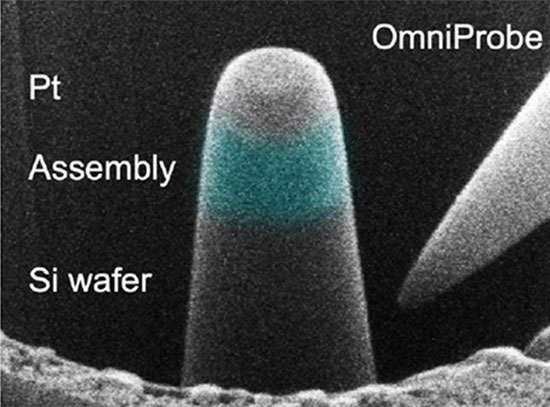

Using a process called thin film solid-state interfacial dealloying (SSID), the scientists used heat to drive a self-organizing process in which metals mix or de-mix to form a new structure. To investigate their newly formed structure, the scientists took a multimodal analysis approach, combining multiple electron- and x-ray-based techniques to visualize and characterize the formation of the bi-continuous structure.

The team identified the dealloyed bi-continuous structure of magnesium (Mg), iron (Fe) and nickel (Ni) through complementary electron microscopy techniques at the Center for Functional Nanomaterials (CFN) and x-ray synchrotron techniques at two beamlines, the Hard X-ray Nanoprobe (HXN) and Beamline for Materials Measurement (BMM), at the National Synchrotron Light Source II (NSLS-II). The NSLS-II and CFN are U.S. Department of Energy Office of Science User Facilities located at Brookhaven National Laboratory.

By demonstrating the new concept of thin film-SSID, this research sets directions for future work in fundamental studies for mechanistic understanding, innovation, and developing applications.

Download the research summary slide

Related Links

Feature Story: “Turning Up the Heat to Create New Nanostructured Metals”

Contact

Yu-Chen Karen Chen-Wiegart

Stony Brook University

Karen.Chen-Wiegart@stonybrook.edu

Publications

C. Zhao, K. Kisslinger, X. Huang, M. Lu, F. Camino, C.H. Lin, H. Yan, E. Nazaretski, Y. Chu, B. Ravel, M. Liu, Y.C.K. Chen-Wiegart. “Bi-continuous Pattern Formation in Thin Films via Solid-State Interfacial Dealloying by multimodal characterization”. Materials Horizons, 6, 1991-2002 (2019). DOI: 10.1039/c9mh00669a

Funding

This material is based on work supported by the National Science Foundation under Grant No. DMR-1752839. Karen Chen-Wiegart acknowledges the support provided via the Faculty Early Career Development Program (CAREER) program and Metals and Metallic Nanostructures program of National Science Foundation. This research used resources, HXN (3-ID) and BMM (6-BM) beamlines, of the National Synchrotron Light Source II, a US Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Brookhaven National Laboratory under Contract No. DE-SC0012704. This research used resources of the Center for Functional Nanomaterials, which is a U.S. DOE Office of Science Facility, at Brookhaven National Laboratory under Contract No. DE-SC0012704. Karen Chen-Wiegart, Chonghang Zhao and Cheng-Hung Lin acknowledge the financial support by the Department of Materials Science and Chemical Engineering, the College of Engineering and Applied Sciences, and the Stony Brook University, as well as by the Brookhaven National Laboratory. Chonghang Zhao and Karen Chen-Wiegart are grateful for the support of a student fellowship by the Joint Photon Science Institute at Stony Brook University.

2020-17168 | INT/EXT | Newsroom