Thea Vijaya Kumar Coordinates Mechanical Cooling Systems for EIC

Intern turned full-time engineer addresses challenges for Lab's next particle collider

July 29, 2024

enlarge

enlarge

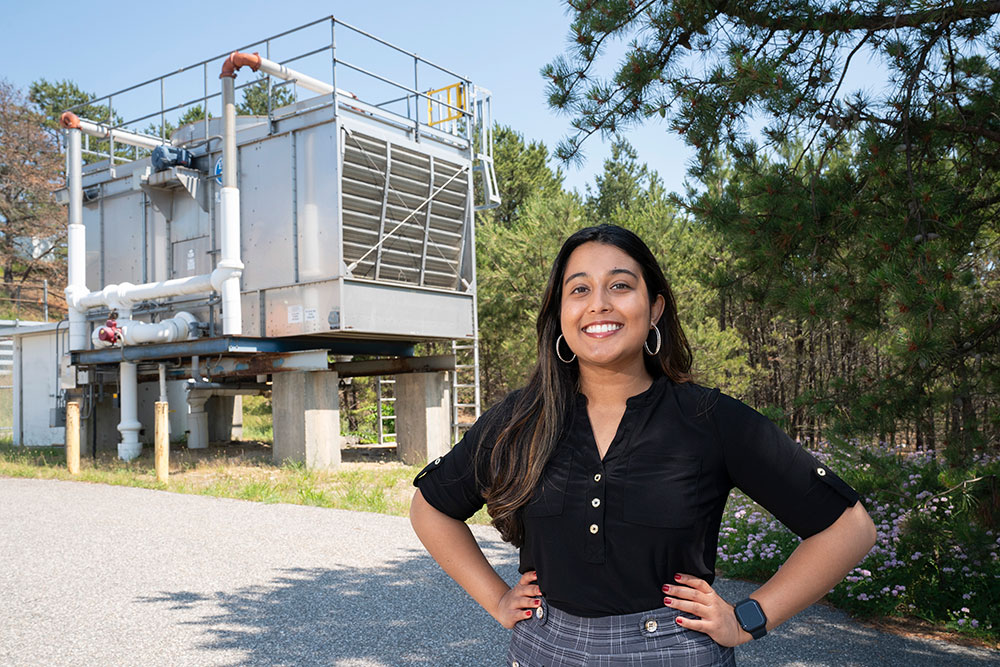

Brookhaven Lab engineer Thea Vijaya Kumar in front of a cooling tower adjacent to the ring of the Relativistic Heavy Ion Collider (RHIC). The tower cools accelerator equipment in RHIC and will also likely play a cooling role in the future Electron-Ion Collider (EIC). (Jessica Rotkiewicz/Brookhaven National Laboratory)

What do a particle collider and a human have in common? Not much. But both have parts that need to be kept within a certain temperature range to function properly. It’s a phenomenon mechanical engineer Thea Vijaya Kumar knows well. She designs systems to keep people and machines cool — a cool job in every sense of the word. Her current focus is on meeting that goal, and how to do it efficiently, for the Electron-Ion Collider (EIC), a major nuclear physics research facility in the planning phase at the U.S. Department of Energy’s Brookhaven National Laboratory.

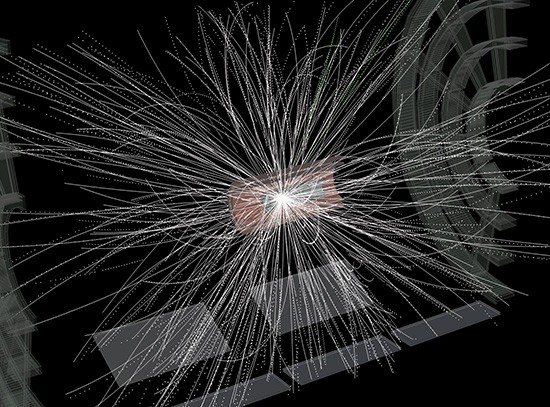

Set to be constructed where the Relativistic Heavy Ion Collider (RHIC) presently operates, the EIC will act like an ultraprecise electron microscope to see inside protons and atomic nuclei. It will produce 3D snapshots of those particles’ internal structure and reveal the dynamic interactions of their “quark” and “gluon” building blocks with extraordinary resolution beginning in the early 2030s.

Of course, it takes physicists, engineers, and technicians — people — to make this vision reality.

“If we don't provide cooling for the equipment, it can overheat, and it could fail,” said Vijaya Kumar, an engineer in the Mechanical Cooling Systems group of the EIC’s Infrastructure Division. The same could be said for the people who will run the EIC. Vijaya Kumar’s work addresses the need to keep both cool.

In addition to working on heating, ventilation, and air conditioning (HVAC) for buildings, Vijaya Kumar specializes in water cooling for accelerator support equipment, both in new buildings being constructed as part of the EIC project and in the accelerator tunnel itself. This method relies on water flowing through magnets, beampipes, and electronics with integrated cooling passages (built-in channels) to lower their temperature.

“The water-cooling method is what we use in some of the RHIC equipment currently,” Vijaya Kumar clarified. “Water is one of the best ways to remove large amounts of heat from the accelerator equipment, and the EIC will require a lot of it.”

Second time is the charm

It’s apt that Vijaya Kumar is working on a future particle accelerator because her career trajectory has been all momentum. Prior to converting to a full-time staffer, she participated in three internships at Brookhaven — a testament to the success of DOE's Science Undergraduate Laboratory Internship (SULI) program and the Lab's other efforts to train the next generation of scientists and engineers.

enlarge

enlarge

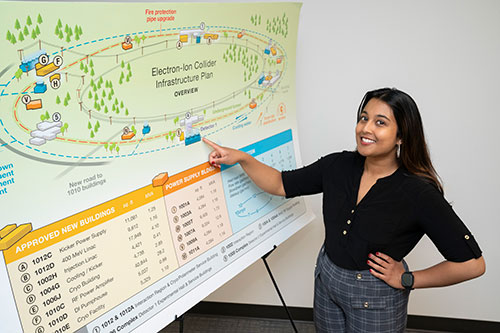

Vijaya Kumar with a schematic of the future Electron-Ion Collider (EIC), a 2.4-mile-circumference accelerator with 16 adjacent buildings, nine hosting both water-cooling and accelerator equipment. The remaining buildings will contain only accelerator equipment or only water-cooling equipment. (Jessica Rotkiewicz/Brookhaven National Laboratory)

The second internship, in particular, prepared Vijaya Kumar for her job today. As a student within the infrastructure team at the time, she learned to use a software program called AFT Fathom to simulate water cooling for half the future EIC while another intern modeled the second half. The project included cooling for the EIC’s support buildings, plus the main electron accelerator ring and storage ring. Electrons will get accelerated by the former and then injected into the latter before colliding with protons or other ions.

“The models calculate [the cooling water’s] pressure, velocity, flow rate, temperature, and more, depending on what parameters we want to see,” Vijaya Kumar elaborated. Using fluid dynamics and heat transfer equations, she creates a model and inputs information for pipes, pumps, heat exchangers, and valves, and then the program outputs a full system simulation.

Vijaya Kumar recalls that it took her a month to learn the AFT Fathom program as an intern, but it’s a tool that remains directly relevant to her role today.

Charles Folz, Vijaya Kumar’s supervisor and director for the EIC’s Infrastructure Division, noted, “Thea’s rapidly expanding engineering knowledge of the systems and analysis and design tools made for an easy transition to staff engineer. Since joining our staff, she has performed work on sustainability and reliability, requirements collection, design review and optimization, value engineering, and systems integration.”

Keep on keeping cool

The present EIC design has water cooling throughout the entire four-kilometer tunnel by dividing it into six sections and allotting a pump station for cooling equipment to each. The EIC will have 16 buildings in total, with nine hosting both water-cooling and accelerator equipment. The rest will contain only accelerator equipment or only water-cooling equipment. The biggest heat loads come from the radio frequency systems that will accelerate the EIC’s beam particle bunches.

The infrastructure team is now collaborating with HDR, an architect-engineering firm responsible for all mechanical systems design, including HVAC and cooling water systems. Vijaya Kumar emphasized how HVAC provides cooling for people and machines alike, which both release heat into buildings.

“Some HVAC for EIC buildings will be strictly to keep equipment cool, while other buildings’ HVAC systems factor in occupancy,” she noted.

“The challenge is mostly with the equipment since some machines require strict temperature ranges to operate properly, whereas people can handle larger ranges of temperature,” Vijaya Kumar said. Her team must account for humidity levels, too. Humidity makes people uncomfortable, but depending on its intensity, humidity can also cause conductivity changes, moisture damage, or static electric charge buildup in sensitive electronics. “Our concern is therefore more with the equipment being able to function.” In fact, Vijaya Kumar’s work has a meta side, as she helps cool cryogenic machinery responsible for keeping other things cool.

To fully protect functionality, cryogenic or otherwise, the engineering team incorporates “redundancy,” meaning they install adjacent backup equipment ready to ramp up at a moment’s notice. That takes a lot of planning to orchestrate. On a typical day, Vijaya Kumar “gets the analytics for which buildings have the highest heat loads, how much equipment is in each area, and where the highest concentrations of both of those parameters are.” Folz added that her job entails “accessing historical information and recording trends to help make informed decisions about control parameters and equipment selection for new systems.”

Another priority for ensuring smooth operations, Vijaya Kumar said, is “traceability” — meaning her team distinguishes in their records between assumptions and hard information about equipment and conditions. Here’s a hypothetical scenario: Say the group is choosing a vendor for new accelerator equipment. They might know for sure that no matter what vendor they pick, the same water supply temperature requirements will apply. However, different vendors’ products might handle drops in pressure differently. Knowing that supply temperature is a hard requirement while the pressure drop is documented as an assumption can help them make an informed choice.

The work is extremely detail-oriented. Vijaya Kumar regularly considers troubleshooting questions such as, “Is there enough space for our equipment in that location? Are there any issues with the topography [or the surface] of the land? Are there existing utilities that we can tie into? Do the designs that we received from our engineering firm make sense with what we have on site?”

enlarge

enlarge

When she's not designing cooling systems, Vijaya Kumar enjoys visiting the Long Island Tulip Festival in Manorville, NY, traveling to other countries such as Greece, and hanging out with her two pet cats, Rex (left) and Missy (right). (Courtesy of Thea Vijaya Kumar)

Applying herself to applied science

Vijaya Kumar was first drawn to Brookhaven at a career fair when she was an undergraduate at Stony Brook University. She got the sense that, at the Lab, “you can talk to a scientist or an engineer and ask questions, and you don't feel like you're asking dumb questions.”

That observation still rings true, she said. “I work with so many brilliant people, but they're just so humble, and they're willing to teach others.”

Such communication is essential in jobs that require problem-solving, she noted. “You're going to meet a lot of different types of people in many different disciplines. You need to know how to talk to people and get information.”

She is grateful for her positive experience as a female engineer. “When I was an intern, I was treated the same way as everybody else. Same thing now. We have a wide range of age, race, and gender in our group. My team makes sure that everybody is heard.”

Vijaya Kumar credits her father for being a big proponent of her career. He was originally interested in engineering himself but pursued a different path. His support for her remained strong, though, she said.

“I am lucky that he wanted me to be independent and highly educated, even in a field where women were a minority,” she noted.

Having moved to the United States at seven years old after briefly living in India and England, Vijaya Kumar also highlighted the role teachers and college professors played in inspiring and supporting her interest.

“We had technology classes every year since I was in fifth grade,” she recalled. “I loved that I was able to build things with my own hands,” she said, fondly remembering a lamp she built in machine shop that she still uses today — even while helping to build the world’s “coolest” new particle collider.

Brookhaven National Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit science.energy.gov.

Follow @BrookhavenLab on social media. Find us on Instagram, LinkedIn, X, and Facebook.

2024-21935 | INT/EXT | Newsroom