About the National Synchrotron Light Source II

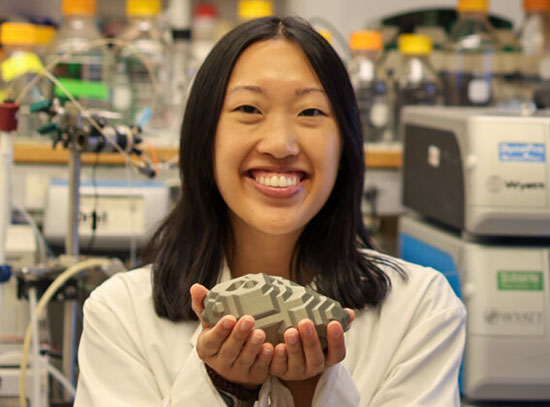

From batteries and microelectronics to drug design and cultural heritage, scientists advance our understanding of many materials every day to solve the world’s greatest challenges. However, today's problems are so complex that they require scientists to study materials with highly specialized tools and expertise that are not readily available at most institutions.

That’s where the National Synchrotron Light Source II (NSLS-II) comes in. As one of the newest, most advanced synchrotron facilities in the world, NSLS-II enables its growing research community to study materials with nanoscale resolution and exquisite sensitivity by providing cutting-edge capabilities.

The facility’s state-of-the-art, medium-energy electron storage ring (3 billion electron-volts) generates ultrabright, highly stable beams of light, ranging from infrared to hard x-rays, to run 29 experimental stations, or beamlines. Each of our beamlines offers unique research tools to reveal the electronic, chemical, and atomic structure of materials.

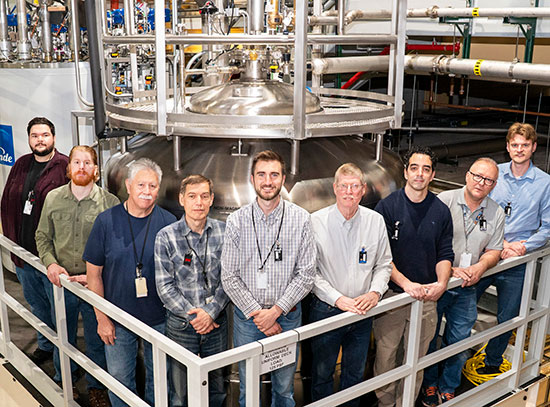

Together with visiting researchers (users) and partners from all around the world, interdisciplinary teams at NSLS-II explore materials, focus on the most important challenges in science and technology. Learn more about this U.S. Department of Energy (DOE) Office of Science User Facility.

NSLS-II News

Science Highlights

Stay informed! Subscribe to our triannual newsletter, News @ NSLS-II.

Announcements

-

NSLS-II User Access for National Security, Space Agencies, and Defense Mission-Related Research (PDF)

-

Sign up to receive NSLS-ll Machine Operating Status Updates by email

See all

Seminars / Events

- JAN9Friday

NSLS-II Friday Lunchtime Seminar

Efficient 2D/3D XAS Imaging

Friday, January 9, 2026, 12 p.m., NSLS-II Bldg. 743 Room 156

- JAN16Friday

NSLS-II Friday Lunchtime Seminar

Real-time Virtual Beamline Optimization with XRT and Blop

Friday, January 16, 2026, 12 p.m., NSLS-II Bldg. 743 Room 156

Conferences / Workshops

Affiliated Facilities at Brookhaven Lab

The Center for BioMolecular Structure (CBMS) is a suite of synchrotron beamlines and associated laboratories dedicated to studying life from the behavior of its molecular building blocks to their influence on Earth’s environment. CBMS offers a research environment that supports visiting researchers, partners, and collaborators in their research by combining staff expertise with a suite of advanced synchrotron tools including macromolecular crystallography, biological X-ray scattering, and X-ray fluorescence microscopy.

The Laboratory for BioMolecular Structure (LBMS) is a cryo-electron microscopy center whose mission is to accelerate our understanding of fundamental molecular structures. LBMS offers high-resolution data collection for single particle work, molecular tomography electron microscopy, and cellular tomography electron microscopy. The laboratory is located next door to CBMS’s x-ray imaging and structural biology capabilities, which enables shared resources and expertise across both facilities.

The Center for Functional Nanomaterials (CFN) explores the unique properties of materials and processes at the nanoscale. It is a user-oriented research center whose mission is to be an open facility for the nanoscience research community to advance research in fields as diverse as efficient catalysts, fuel cell chemistries and architectures, and photovoltaic components.

User Services Office

Brookhaven National Laboratory

743 Brookhaven Avenue

Building 743

Upton, NY 11973-5000

(631) 344-8737 | nsls2user@bnl.gov | website

For Vendors & Contractors

If you are a contractor or vendor coming to NSLS-II for the day, please work with your host to gain access to the Lab site. If you will be on site for more than one day, please contact the Guest, User, and Visitor Center for access and training requirements. See maps and directions for getting here.