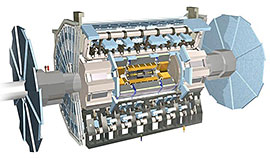

ATLAS Muon Spectrometer

Brookhaven National Laboratory led the development of the 32 muon detectors in the inner ring of the ATLAS detector's "small wheels." (A small wheel is shown here being lowered into the LHC tunnel.) The wheels are covered with sensitive detectors that will be used to identify and measure the momentum of subatomic particles called muons that are created in collisions at the LHC. Image credit: CERN.

Muons are particles that are very similar to electrons but 200 times more massive. Unlike electrons, however, muons are not stopped by the first components of ATLAS. Instead, they zip through the inside parts of the experiment, to be detected by the muon spectrometer.

The muon spectrometer is organized into three stations surrounding the central and lateral parts of the experiment. Brookhaven developed and tested the components that lie closest to the interaction point. These stations are disk-shaped (with a hole in the middle), each disk being composed of trapezoidal modules that overlap radially with each other. At a distance of 7 meters from the interaction point, the muon detectors will be particularly vulnerable to the high-radiation environment produced by the colliding high-energy protons.

These muon detectors are called cathode strip chambers, which are

read out by electronics mounted on the detectors. The collected signals

are then sent through optical fibers to the experiment's control room

for further processing.

A module of cathode strip chambers is composed of five panels of

longitudinal or transversal strips (the cathode strips), with anode

wires woven between the panels and glued with epoxy on the sides of the

panels. The space enclosing the wires between the panels is filled with

a gas mixture of argon and carbon dioxide.

A team of Brookhaven physicists, engineers and technicians tested the quality of cathode strip chamber components produced in industry and assembled the chambers. To achieve the required performance, for example, the distance between the planes needs to be uniform to within 50 microns. So the scientists made sure that no distortion of more than 50 microns was detected on the panel surfaces. The team also tested the tensions of the wires to make sure the wires stay parallel to each other and the distance from the panel surface to the wire is constant along the wire.

See also: Brookhaven contributions to the ATLAS calorimeter.